Tel:

+8615930870079

Tel:

+8615930870079

Nov . 18, 2024 01:00 Back to list

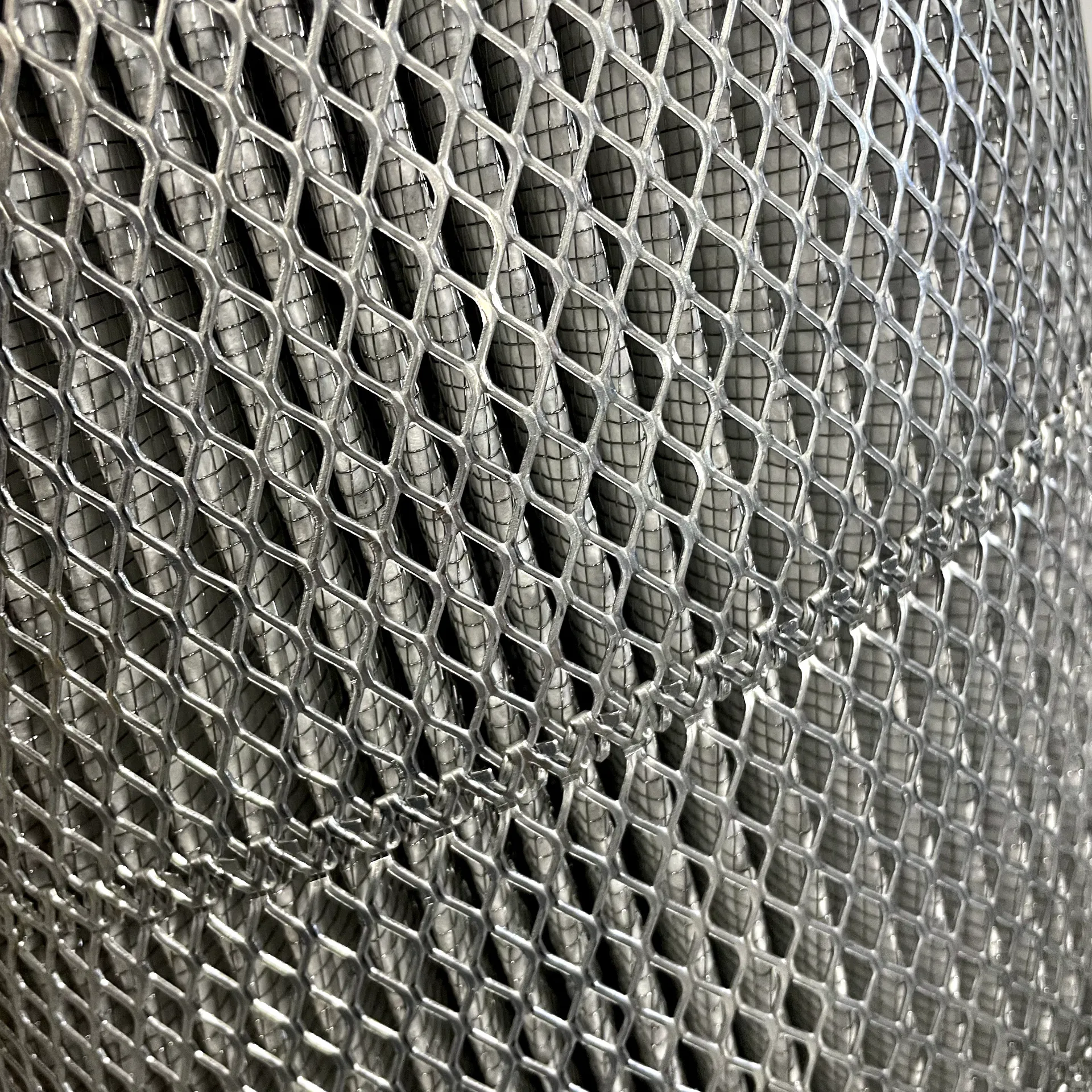

antistatic filter element

Understanding Antistatic Filter Elements Importance and Applications

In various industrial applications, dust and particulate contamination can pose significant challenges to both equipment performance and product quality. This is particularly true in environments where static electricity can cause sparks, potentially leading to dangerous explosions or damaging sensitive electronic components. To mitigate these risks, antistatic filter elements play a crucial role in maintaining a safe and efficient working environment.

What Are Antistatic Filter Elements?

Antistatic filter elements are specially designed air or liquid filters that incorporate materials with antistatic properties. These filters are engineered to reduce or eliminate the build-up of static electricity, thereby preventing dust and other particles from clinging to filter surfaces. The technology behind these filters often involves the addition of conductive materials, such as carbon fibers or other conductive agents, that safely dissipate static charges before they can accumulate.

The Importance of Antistatic Filter Elements

1. Safety In environments where flammable gases or dust are present, static electricity can create sparks. Antistatic filters significantly lower the risk of ignition and explosion. Therefore, they are commonly utilized in industries like chemical manufacturing, pharmaceuticals, and food processing.

2. Protecting Equipment Static electricity can cause damage to sensitive electronic components. Antistatic filter elements help maintain the integrity of equipment by ensuring that only clean, particle-free air or liquid is circulated through systems. This is particularly essential in sectors such as semiconductor manufacturing, where even the smallest dust particles can lead to product defects.

3. Enhanced Filtration Efficiency The unique properties of antistatic filter materials ensure that particles are more effectively captured. The reduction of static cling means that particles that might otherwise settle or accumulate on filter surfaces are effectively drawn into the filter media, leading to greater overall filtration efficiency.

4. Longer Filter Life By preventing the build-up of static charge, antistatic filter elements can also prolong the life of the filters themselves. When particles cling less to the filter surface, the filters can maintain their performance over longer periods, reducing the frequency of replacements and associated costs.

antistatic filter element

Applications of Antistatic Filter Elements

Antistatic filter elements find applications in various fields

- Electronics Manufacturing Cleanrooms in electronics manufacturing require stringent control of particulate contamination. Antistatic filters help maintain these environments by ensuring that any airborne particles do not interfere with the production process.

- Pharmaceutical Production In pharmaceutical facilities, even minute levels of static electricity can affect product quality. Antistatic filters are essential for ensuring that products meet strict regulatory standards.

- Paint and Coating Industries In industries where spray painting or coating is performed, static electricity can cause paint to repel from surfaces, leading to uneven coatings. The use of antistatic filters helps mitigate this issue, ensuring a smooth and consistent finish.

- Food Processing The food industry also benefits from the use of antistatic filters, particularly in processes where airborne particulates can contaminate food products. These filters ensure a safe environment for food production.

Conclusion

Antistatic filter elements are an essential technology in many industrial sectors, providing safety, efficiency, and enhanced product quality. By controlling static electricity and improving filtration, these elements play a vital role in protecting both people and equipment. As industries continue to evolve and the demand for clean and safe working environments grows, the importance of antistatic filter elements will undoubtedly increase, reflecting a commitment to both safety and innovation in industrial practices. As we move forward, investing in advanced filtration technologies will be crucial for ensuring sustainable and safe industrial operations.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: