Tel:

+8615930870079

Tel:

+8615930870079

Sep . 28, 2024 06:59 Back to list

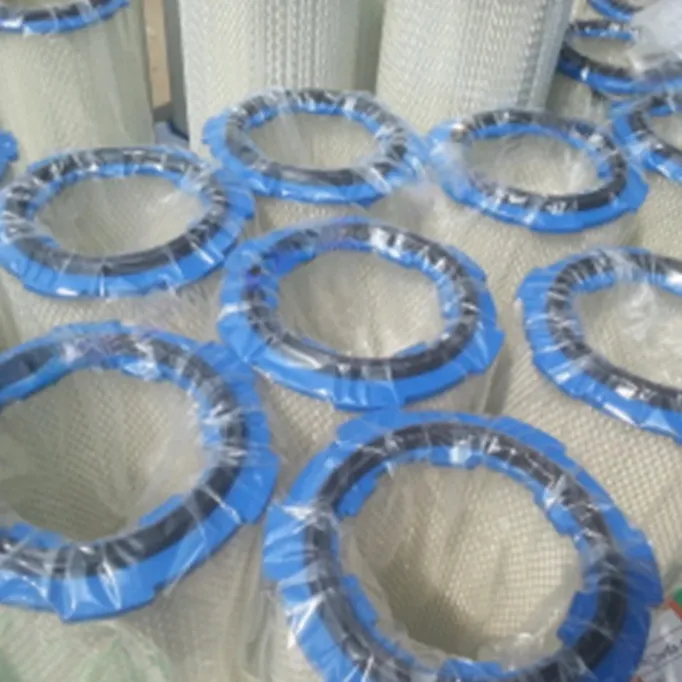

Antistatic Filter Components for Enhanced Performance and Safety in Sensitive Environments

The Importance of Antistatic Filter Elements in Industrial Applications

In an age where technology permeates every aspect of our daily lives, the importance of maintaining optimal performance and safety standards in various industrial applications cannot be overstated. One such crucial component that plays a significant role in this regard is the antistatic filter element. These specialized filters are engineered to mitigate the risks associated with static electricity, ensuring operational efficiency and safety in environments where dust and airborne particles pose a threat.

Static electricity is generated by the friction between two surfaces, which can lead to the accumulation of electrical charges on various materials. In industrial settings, this buildup can create hazardous situations, potentially resulting in equipment malfunctions, fires, or even explosions. With the increasing implementation of automation and advanced machinery, the accumulation of fine particulate matter can exacerbate static-related risks. This is where antistatic filter elements come into play.

Antistatic filter elements are designed to not only trap harmful particles but also dissipate static charges effectively. They often incorporate conductive or dissipative materials that allow for the safe discharge of static electricity. This feature helps maintain a balanced environment, preventing the dangerous sparking that can ignite flammable substances or damage sensitive electronic components.

The applications of antistatic filter elements are diverse, covering a wide range of industries. In the pharmaceutical sector, for instance, these filters are vital in maintaining air quality and preventing contamination. Dust and fine particles can compromise product integrity, and the introduction of static charge can lead to the explosion of combustible substances. Using antistatic filters ensures that environments remain sterile while also being safe from static discharge risks.

antistatic filter element

Similarly, the electronics industry benefits significantly from these filtration systems. Manufacturing processes often involve sensitive components that can be adversely affected by static electricity. Dust and other contaminants can also impair the functionality of electronic devices, leading to increased failure rates or inefficiencies. Antistatic filter elements mitigate these risks by ensuring that the air is clean and free from static charges, thus protecting both workers and products.

Moreover, the automotive industry relies on antistatic filters during production processes. The assembly lines, often bustling with activity, involve various materials that can generate static. Filters placed in paint booths or during assembly can prevent particles from settling on surfaces and affecting the quality of paintwork or electronic fittings. Through the use of antistatic technology, manufacturers can enhance quality control measures, improve surface finishes, and protect delicate electronic parts.

When selecting antistatic filter elements, several factors should be considered. The nature of the application, the type of contaminants present, and the environment in which the filter will operate are all critical points of assessment. Filters should be compatible with the specific machinery and processes used, ensuring that they do not introduce additional risks or complications. Furthermore, ongoing maintenance and regular replacement of filter elements are necessary to maintain their effectiveness in static charge dissipation and particle capture.

In conclusion, antistatic filter elements are an indispensable part of modern industrial applications, offering both safety and efficiency. As industries continue to evolve, the demand for reliable air filtration solutions that counteract static electricity will only grow. By integrating these advanced filters into their processes, industries can safeguard their operations, protect their products and enhance overall performance. Investing in antistatic filter technology is not just a matter of compliance; it’s a step towards ensuring operational excellence and safety in our ever-evolving industrial landscape.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: