Tel:

+8618931101301

Tel:

+8618931101301

Sep . 22, 2024 00:15 Back to list

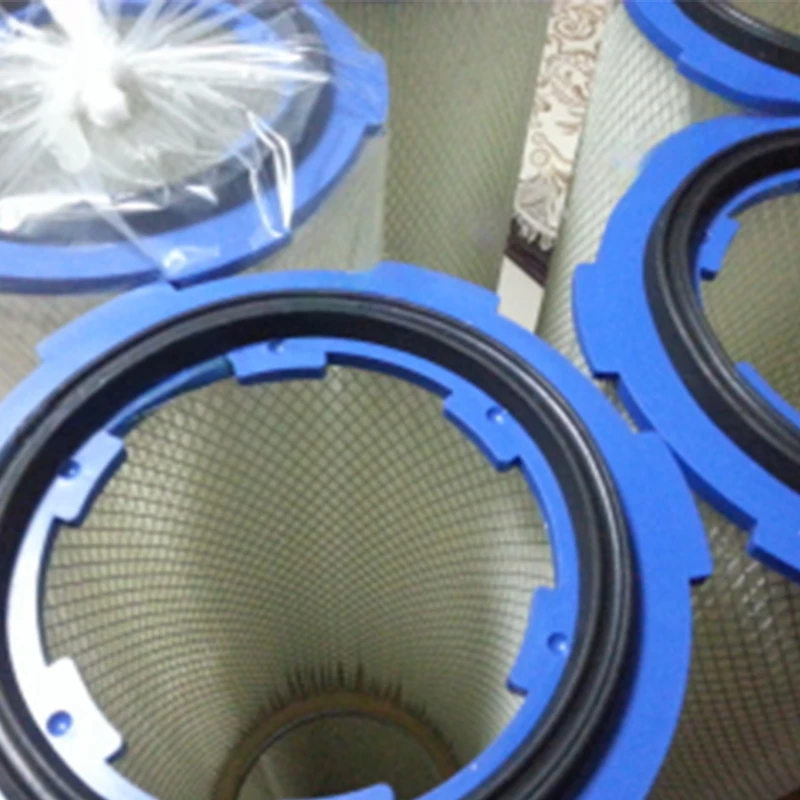

antistatic filter element

Antistatic Filter Elements Importance and Applications

In an increasingly technology-driven world, the significance of managing static electricity cannot be overstated. Antistatic filter elements are a crucial component for various industries that require the control of static charge to ensure the safe and efficient operation of processes and machinery. These filter elements are specifically designed to prevent the accumulation of static electricity, which can lead to significant hazards, including sparks, equipment failure, and contamination.

Static electricity is generated by the movement of materials, which can produce a charge that adheres to surfaces. In environments where flammable gases, powders, or liquids are present, this static buildup can create dangerous conditions that may lead to fires or explosions. In industries such as pharmaceuticals, food processing, and electronics manufacturing, the presence of static electricity poses a risk not only to workers but also to product quality. Consequently, the use of antistatic filter elements becomes essential.

Antistatic filter elements are made from materials that have conductive or dissipative properties. These materials allow for electrostatic charge to flow safely away from surfaces, reducing the likelihood of static build-up. These filters can be integrated into various systems, including air filtration, fume extraction, or vacuum systems, ensuring a controlled environment free from hazardous static discharges.

antistatic filter element

The use of antistatic filter elements is particularly beneficial in cleanrooms, where even microscopic levels of contamination from static electricity can affect product integrity. In such environments, particles charged with static electricity can cling to surfaces or materials, leading to contamination of sensitive products. By employing specialized filter elements, companies can maintain the stringent standards required in cleanroom operations and improve overall product quality.

Moreover, in the electronic industry, antistatic measures are vital to prevent damage to sensitive components. Electronic devices can be severely affected by electrostatic discharge (ESD), which can prematurely degrade or destroy items like printed circuit boards (PCBs). Antistatic filter elements help to mitigate this risk, playing a crucial role in both the manufacturing and packaging processes of electronic devices.

The benefits of integrating antistatic filter elements go beyond safety; they can also enhance operational efficiency. By preventing static-related disruptions, businesses can maintain productivity and avoid costly downtime related to equipment malfunctions. Antistatic filters contribute to a safer working environment, ensuring that employees can focus on their tasks without concern for static-related incidents.

In conclusion, the importance of antistatic filter elements cannot be underestimated in various industries. As the demand for high-quality, safe products continues to grow, these components will remain critical. Understanding their role and implementing effective antistatic measures is essential for any organization that prioritizes safety, quality, and operational excellence. Investing in the right filtration technologies will not only protect employees and products but will also ensure long-term success in an ever-evolving industrial landscape.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: