Tel:

+8615930870079

Tel:

+8615930870079

Aug . 09, 2025 03:00 Back to list

Activated Carbon Air Filter Cartridge: Odor & VOC Removal

In an era where air quality significantly impacts public health and industrial operations, the demand for sophisticated air filtration solutions has never been higher. Among the myriad of technologies available, the activated carbon air filter cartridge stands out as a critical component, offering unparalleled efficiency in removing gaseous pollutants, odors, and Volatile Organic Compounds (VOCs). This comprehensive guide delves into the essence of these essential air filtration components, covering industry trends, technical specifications, application versatility, manufacturing excellence, and why choosing the right partner is paramount.

Industry Trends and the Evolving Landscape of Air Filtration

The global air purification market is experiencing robust growth, driven by increasing public awareness of air pollution's health impacts, tightening environmental regulations, and the expansion of industrial sectors. Key trends include:

- Focus on VOC and Odor Removal: Beyond particulate matter, there's a growing emphasis on eliminating gaseous contaminants, which activated carbon excels at.

- Smart Filtration Systems: Integration of IoT and AI for real-time air quality monitoring and predictive maintenance of filter cartridges, optimizing replacement cycles.

- Sustainability: Demand for eco-friendly manufacturing processes, longer-lasting filters, and eventually, recyclable or regenerable filter media.

- Specialized Applications: Increasing need for customized solutions in niche industries, such as cleanrooms, laboratories, and specialized industrial processes requiring specific gas removal.

- Post-Pandemic Air Quality Concerns: Heightened awareness in commercial and residential settings, pushing for better HVAC filtration beyond MERV ratings to include chemical filtration.

According to a recent market analysis by Grand View Research, the global air purification market size was valued at USD 12.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 10.7% from 2023 to 2030, with a significant portion attributed to advanced filtration media like activated carbon for specialized applications.

Understanding the Technical Core: Parameters of a High-Performance Activated Carbon Air Filter Cartridge

An activated carbon air filter cartridge functions primarily through adsorption, a process where molecules of gas, odor, or VOCs adhere to the vast porous surface of the activated carbon. The effectiveness of an activated carbon air filter cartridge is determined by several critical technical parameters:

- Type of Activated Carbon: Coconut shell-based (high hardness, good for small molecules), coal-based (cost-effective, broad-spectrum), wood-based (large pore size, good for larger molecules).

- Carbon Impregnation: Carbon can be impregnated with chemicals (e.g., potassium permanganate, potassium iodide) to enhance removal of specific gases like hydrogen sulfide, ammonia, or formaldehyde through chemisorption.

- Adsorption Capacity: Measured in terms of iodine number (for micropores), CTC (Carbon Tetrachloride) adsorption rate (for overall gas adsorption efficiency), or specific pollutant removal percentage. Higher values indicate better performance. Typical CTC values range from 50% to 70% for standard applications.

- Pressure Drop: The resistance to airflow across the filter. Lower pressure drop translates to reduced energy consumption for fans and blowers. Manufacturers strive for optimal balance between filtration efficiency and minimal pressure drop.

- Filter Dimensions and Configuration: Length, diameter, and shape (e.g., cylindrical, panel, V-bank) designed to fit specific HVAC systems or industrial machinery.

- Housing Material: Often made from galvanized steel, stainless steel, or robust plastics to ensure durability and resistance to corrosion, depending on the application environment.

- Operating Temperature and Humidity: Activated carbon performance can be affected by extreme conditions. Most cartridges perform optimally within a specific range (e.g., 40-100°F and 30-70% relative humidity).

Typical Specifications for an Activated Carbon Air Filter Cartridge

| Parameter | Description | Typical Value Range |

|---|---|---|

| Media Type | High-quality granular activated carbon (GAC) or activated carbon fiber (ACF) | Coconut Shell, Coal-based, Wood-based |

| Carbon Weight/Content | Amount of activated carbon in the cartridge | 1 kg - 50 kg+ per cartridge (varies by size) |

| CTC Adsorption Rate | Carbon Tetrachloride adsorption efficiency | ≥ 50% (Standard), ≥ 70% (High-Performance) |

| Iodine Number | Measure of micropore volume and surface area | 900 - 1200 mg/g |

| Initial Pressure Drop | Airflow resistance at rated airflow | Typically |

| Service Life | Expected operational duration before replacement | 6 months to 2 years (application-dependent) |

| Operating Temperature Range | Ambient temperature conditions for effective operation | -20°C to 80°C (-4°F to 176°F) |

| Housing Material | Outer shell material for durability | Galvanized Steel, Stainless Steel, ABS Plastic |

Diverse Application Scenarios of Air Filtration Cartridges

The versatility of an air filter cartridge containing activated carbon makes it indispensable across numerous sectors:

- HVAC Systems: Enhancing Indoor Air Quality (IAQ) in commercial buildings, hospitals, schools, and residences by removing odors, smoke, and common indoor VOCs from paints, cleaning products, and furnishings.

- Industrial Processes: Critical for exhaust air treatment in chemical plants, petrochemical facilities, pharmaceutical manufacturing, food processing, and waste treatment plants to meet strict emission regulations and protect workers.

- Museums and Archives: Protecting valuable artifacts and documents from gaseous pollutants that can cause degradation.

- Cleanrooms: Used in semiconductor manufacturing, biotechnology, and healthcare facilities to ensure ultra-pure air by removing trace molecular contaminants (AMCs) that could compromise sensitive processes or sterile environments.

- Laboratories: Fume hood exhaust and general lab air purification to remove solvent vapors, acidic gases, and other hazardous fumes.

- Grow Facilities: Neutralizing odors from cannabis cultivation and other horticultural operations.

Technical Advantages: Why Activated Carbon is Superior

Compared to other filtration methods, the cartridge filter air containing activated carbon offers distinct advantages:

- Broad-Spectrum Adsorption: Effectively removes a wide range of organic and some inorganic gaseous contaminants, including VOCs, odors, ozone, and certain toxic gases, unlike particulate filters that only capture solid particles.

- High Efficiency: Capable of achieving high removal efficiencies for specific pollutants, often exceeding 95% for target gases when properly designed and maintained.

- Low Energy Consumption: While some pressure drop is inherent, well-designed air filtration cartridges minimize resistance, leading to energy savings for fan operation compared to less efficient media.

- Non-Hazardous Byproducts: The adsorption process typically converts harmful gases into a solid phase on the carbon surface, preventing the creation of new harmful byproducts.

- Versatility: Can be customized with different carbon types, impregnations, and form factors to target specific pollutants and fit various air purification systems.

- Corrosion Protection: By removing corrosive gases (e.g., H2S, SO2, Cl2) from air streams, these filters protect sensitive electronics and equipment in industrial settings, extending their lifespan and reducing maintenance costs. This offers significant long-term savings.

The Meticulous Manufacturing Process of an Activated Carbon Air Filter Cartridge

The creation of a high-quality activated carbon air filter cartridge is a precise multi-step process, ensuring optimal performance and durability. While methods like casting, forging, and CNC machining are vital for components like pump housings or complex machinery parts, the manufacturing of a filter cartridge focuses on sophisticated material science, precise assembly, and stringent quality control. Here’s a detailed look:

- Raw Material Selection & Activation:

- Material: The process begins with sourcing high-quality raw materials for activated carbon, primarily coconut shells, coal, or wood. These materials are chosen for their high carbon content and potential for developing a porous structure.

- Activation: The raw material undergoes a thermal or chemical activation process.

- Thermal Activation (Pyrolysis & Steam Activation): Raw material is first carbonized (pyrolysis) at high temperatures (600-900°C) in an inert atmosphere, removing non-carbon elements. The resulting char is then exposed to an oxidizing gas (steam, CO2, or air) at elevated temperatures (800-1100°C), creating an intricate network of pores (micropores, mesopores, macropores) that vastly increase the surface area. This process is crucial for the carbon's adsorption capacity.

- Chemical Activation: Raw material is impregnated with a chemical agent (e.g., phosphoric acid, zinc chloride) and then heated to lower temperatures (400-600°C). The chemical agent acts as a dehydrating agent, promoting the formation of pores.

- Carbon Processing & Impregnation (Optional):

- Sizing & Granulation: The activated carbon is then crushed and sieved to specific particle sizes (e.g., granular activated carbon - GAC) or processed into other forms like extruded pellets or activated carbon fiber (ACF), depending on the cartridge design.

- Impregnation: For specialized applications, the carbon may be impregnated with specific chemical compounds (e.g., potassium permanganate, potassium iodide, metal oxides). This enhances the carbon's ability to chemisorb (chemically react with and remove) specific difficult-to-adsorb gases like hydrogen sulfide (H2S), ammonia (NH3), formaldehyde (HCHO), or sulfur dioxide (SO2).

- Cartridge Design & Component Fabrication:

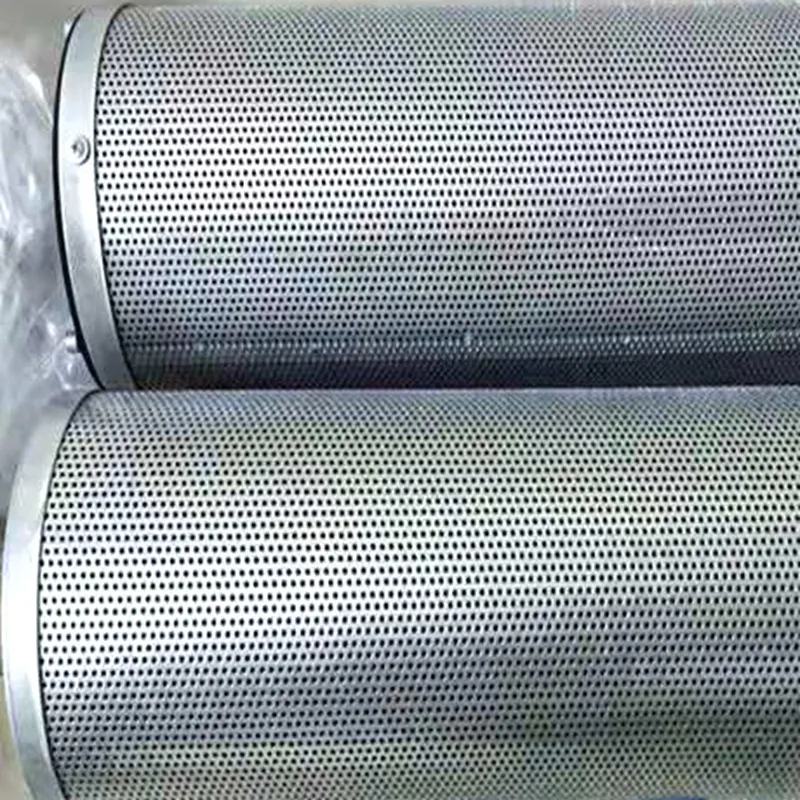

- Housing and Structure: Depending on the type of air filter cartridge, components such as the outer housing (often galvanized steel, stainless steel, or robust ABS plastic), end caps, and internal support structures (e.g., perforated metal cylinders, plastic grids) are fabricated. These often involve processes like precision stamping, welding, or injection molding to ensure robust construction and air-tight sealing.

- Media Containment: The design ensures optimal airflow distribution through the carbon bed and secure containment of the activated carbon media to prevent bypass or dusting. This may involve sophisticated pleating or layering techniques for filter media that incorporates carbon, or simply filling and sealing for granular carbon beds.

- Assembly:

- Media Loading: The pre-processed activated carbon (granular or as a woven/non-woven fabric) is carefully loaded into the prepared cartridge housing. For granular carbon, this involves precise volumetric filling to ensure uniform density and prevent channeling, which could reduce efficiency.

- Sealing: End caps are securely attached, often using advanced bonding agents, ultrasonic welding, or mechanical crimping, to create a leak-proof seal, preventing air bypass around the carbon media.

- Quality Control and Testing:

- Leak Testing: Each air filtration cartridges undergoes rigorous leak testing to ensure no air bypass.

- Pressure Drop Measurement: Filters are tested for initial pressure drop at rated airflow, ensuring they meet design specifications and minimize energy consumption.

- Adsorption Performance Testing: Sample cartridges or batches are tested according to industry standards (e.g., ASTM D3467 for CTC adsorption, ASTM D4607 for iodine number) to verify adsorption capacity and removal efficiency for target pollutants. This involves exposing the filter to a known concentration of a challenge gas and measuring the breakthrough time.

- Structural Integrity: Visual inspections and burst strength tests ensure the cartridge can withstand operational pressures.

- Compliance: Products are manufactured and tested to comply with international standards such as ISO 9001 (Quality Management Systems), ASHRAE 52.2 (for particulate filters, though activated carbon is for gaseous contaminants, often filters are dual-purpose), and potentially specific environmental regulations like CARB (California Air Resources Board) if applicable for certain applications.

The entire process, from raw material to finished filter cartridge air, emphasizes precision, quality, and adherence to stringent standards, ensuring a reliable and high-performing product. The benefits in typical applications include significantly improved indoor air quality, protection of sensitive equipment from corrosive gases, and compliance with stringent environmental regulations, often leading to enhanced energy efficiency by optimizing system performance and reducing system downtime.

Choosing Your Partner: Manufacturer Comparison

Selecting the right manufacturer for your filter cartridge air needs is crucial for long-term performance and cost-effectiveness. Consider these factors:

| Feature | Manufacturer A (OnlyFilterCartridge.com) | Generic Manufacturer B |

|---|---|---|

| Years of Expertise | 20+ years specializing in air filtration | 5-10 years, broader product range |

| Certifications | ISO 9001:2015 Certified, ASHRAE 52.2 adherence, various industry-specific approvals. | Basic ISO certification, limited specific tests. |

| Customization Capability | Extensive customization for carbon type, impregnation, size, housing, and performance. Dedicated R&D team. | Limited standard options, reluctant for bespoke solutions. |

| Quality Control | Rigorous multi-stage QC including third-party testing for adsorption and pressure drop. | Standard in-house checks, minimal third-party validation. |

| After-Sales Support | Dedicated technical support, installation guidance, performance monitoring services. | Basic warranty, limited technical assistance. |

| Customer Feedback/Reputation | Strong positive reputation, numerous case studies, repeat clients in demanding industries. | Mixed reviews, focus on volume over specialized solutions. |

Tailored Excellence: Customization Solutions

One of the significant advantages of working with experienced air filter cartridge manufacturers is the ability to develop customized solutions. Customization ensures that the filter precisely meets the unique challenges of your application, maximizing efficiency and lifespan while minimizing operational costs. OnlyFilterCartridge.com offers comprehensive customization options including:

- Specific Carbon Types: Choosing between coconut shell, coal, or wood-based carbon, or blends, to target specific molecular sizes and types.

- Tailored Impregnation: Developing custom chemical impregnations for the removal of challenging gases like mercury vapor, corrosive acids, or unique odor profiles.

- Dimensions and Housing Materials: Manufacturing cartridges in bespoke sizes, shapes, and using materials (e.g., specific grades of stainless steel, chemical-resistant plastics) to fit existing systems or withstand aggressive environments.

- Optimized Carbon Load: Adjusting the amount and density of activated carbon to achieve desired service life and removal efficiency without excessive pressure drop.

- Multi-Stage Design: Combining activated carbon with other filter media (e.g., HEPA, pre-filters) within a single air filtration cartridges or a modular system for comprehensive particulate and gaseous filtration.

Application Cases and Client Experience

Our activated carbon air filter cartridge solutions have consistently delivered superior results across a wide array of demanding applications, demonstrating our commitment to quality and real-world performance. Below are illustrative examples of how our products provide tangible benefits:

- Case Study 1: Petrochemical Plant VOC Abatement

Challenge: A major petrochemical refinery faced stringent environmental regulations regarding the emission of various VOCs (e.g., benzene, toluene, xylene) from its processing units. Their existing system struggled to meet compliance, incurring potential fines and environmental impact concerns.

Solution: We engineered a specialized activated carbon air filter cartridge system using a high-capacity, coal-based activated carbon impregnated for enhanced aromatic compound adsorption. Our technical team conducted on-site assessments, designed custom-sized cartridges to fit their existing air handling units, and provided detailed installation guidance.

Result: Within weeks of deployment, the plant reported a consistent 98% reduction in target VOC emissions, well within regulatory limits. The improved air quality not only ensured compliance but also significantly enhanced worker safety and community relations. "The reduction in VOCs has been remarkable and consistent," noted their environmental manager. "OnlyFilterCartridge.com's filter cartridge air solution exceeded our expectations, providing a robust and reliable answer to our compliance challenges."

- Case Study 2: Hospital HVAC Odor Control & IAQ Improvement

Challenge: A large urban hospital experienced persistent issues with lingering odors from various sources (e.g., sterilization chemicals, patient care, food services) affecting patient comfort and staff morale. Traditional particulate filters were ineffective against these gaseous contaminants, compromising Indoor Air Quality (IAQ).

Solution: We implemented a phased upgrade to their HVAC system, integrating our specially designed air filtration cartridges with an optimized blend of coconut-shell activated carbon for broad-spectrum odor removal and a small percentage of impregnated carbon for specific medical odors like formaldehyde. The compact design of our air filtration cartridges allowed seamless integration into their existing air handlers with minimal downtime.

Result: The hospital reported a dramatic improvement in IAQ and odor control. Patient satisfaction scores related to environmental comfort significantly increased. Staff noted a fresher, cleaner environment throughout the facility. "The difference is palpable," commented the hospital's facilities director. "The activated carbon air filter cartridge truly transformed our indoor environment, making it more comfortable for everyone."

- Case Study 3: Semiconductor Cleanroom Molecular Contamination Control

Challenge: A leading semiconductor manufacturer required ultra-low levels of airborne molecular contaminants (AMCs) in their cleanroom environments to prevent defects in microchip fabrication. Even trace amounts of organic acids, amines, and dopants could severely impact product yield.

Solution: We provided a bespoke activated carbon air filter cartridge system featuring high-purity, chemically impregnated activated carbon fiber (ACF) media. ACF offers lower pressure drop and superior performance for trace contaminant removal in critical environments. Our solution included continuous monitoring and predictive replacement algorithms to maintain peak performance.

Result: The client observed a significant reduction in critical AMC levels, leading to a measurable increase in manufacturing yield and product reliability. This partnership demonstrated our capability in addressing highly sensitive and technically demanding applications. "Our yield rates improved notably since implementing their air filter cartridge solutions," stated their cleanroom operations manager. "It's a testament to their deep understanding of molecular filtration."

Frequently Asked Questions (FAQ) about Activated Carbon Air Filter Cartridges

To further enhance understanding and address common queries, here’s a professional FAQ:

- Q: What types of pollutants can an activated carbon air filter cartridge remove that HEPA filters cannot?

A: HEPA filters are designed to capture airborne particulates (dust, pollen, mold spores, bacteria, viruses). An activated carbon air filter cartridge, conversely, excels at removing gaseous pollutants, odors, and Volatile Organic Compounds (VOCs) through adsorption. These include chemicals from cleaning products, paints, solvents, cooking odors, pet odors, smoke, and industrial gases like formaldehyde, sulfur dioxide, and hydrogen sulfide. They work in complementary fashion, often used together in comprehensive air purification systems.

- Q: How do I determine the appropriate service life for my air filter cartridge?

A: The service life of an air filter cartridge depends on several factors: the concentration and type of pollutants in the air, the volume of air being processed, the carbon's adsorption capacity (e.g., CTC value, iodine number), and environmental conditions (temperature, humidity). We recommend regular monitoring of air quality (e.g., using VOC sensors) and pressure drop across the filter. A sudden increase in pressure drop or a return of odors/gases indicates the carbon is saturated and the activated carbon air filter cartridge needs replacement. Typical service life ranges from 6 months to 2 years for standard applications.

- Q: What is "impregnated activated carbon" and why is it used in an air filtration cartridges?

A: Impregnated activated carbon is activated carbon that has been treated with specific chemical compounds (e.g., potassium permanganate, potassium iodide, phosphoric acid). This process allows the carbon to not just physically adsorb, but also chemically react with and neutralize certain pollutants, a process known as chemisorption. This significantly enhances the air filtration cartridges' ability to remove difficult-to-adsorb gases like ammonia, hydrogen sulfide, and formaldehyde, which might pass through untreated carbon or require very high concentrations of carbon to adsorb effectively.

- Q: Can an activated carbon air filter cartridge be cleaned or regenerated?

A: For most standard activated carbon air filter cartridge designs used in HVAC and general industrial applications, the carbon cannot be effectively cleaned or regenerated on-site. Once the carbon is saturated with pollutants, its adsorption capacity is exhausted, and the cartridge must be replaced. Industrial-scale activated carbon regeneration facilities exist for very large volumes of carbon, but these are typically for loose bulk carbon, not individual cartridges.

- Q: What is "pressure drop" in the context of an activated carbon air filter cartridge and why is it important?

A: Pressure drop refers to the resistance to airflow as air passes through the activated carbon air filter cartridge. It is the difference in static pressure measured upstream and downstream of the filter. A lower pressure drop indicates less resistance, which translates to lower energy consumption for the fan or blower driving the air through the system. However, a certain amount of pressure drop is necessary for effective filtration. Manufacturers aim to optimize the air filter cartridge design to achieve high filtration efficiency with the lowest possible pressure drop, balancing performance with energy efficiency.

- Q: What industry standards apply to the performance of activated carbon air filter cartridge?

A: While there isn't one single overarching standard specifically for chemical filters like there is for particulate filters (e.g., ASHRAE 52.2 for MERV ratings), manufacturers adhere to several relevant standards: ISO 9001 (for Quality Management Systems), ASTM D3467 (Standard Test Method for Carbon Tetrachloride Activity of Activated Carbon) for adsorption capacity, ASTM D4607 (Standard Test Method for Determination of Iodine Number of Activated Carbon) for porosity, and often specific internal tests based on industry best practices or client requirements for pollutant removal efficiency.

- Q: What is the typical lead time for ordering custom activated carbon air filter cartridge?

A: For standard activated carbon air filter cartridge models, lead times are typically 2-4 weeks. However, for custom-designed air filter cartridge solutions, the lead time can vary depending on the complexity of the design, specific material sourcing (e.g., rare impregnated carbons), and order volume. We work closely with clients to establish realistic timelines, often ranging from 6-12 weeks for initial prototypes and first production runs, followed by faster turnarounds for subsequent orders. Our dedicated customer support team provides transparent communication throughout the entire process.

Delivery and Warranty Information

At OnlyFilterCartridge.com, we understand the importance of timely delivery and reliable products. Our standard delivery lead time for regular orders of activated carbon air filter cartridge is typically 2-4 weeks from order confirmation, subject to stock availability and order volume. For custom or large-volume orders, a detailed production and delivery schedule will be provided. We work with trusted logistics partners to ensure secure and efficient global shipping.

All our air filtration cartridges come with a comprehensive warranty against manufacturing defects. We guarantee that our products meet the advertised specifications and performance parameters. Specific warranty periods vary by product type and application but generally range from 1 to 2 years under normal operating conditions. Our customer support team is readily available to assist with any queries regarding product performance or warranty claims, ensuring your peace of mind.

Conclusion: Breathing Cleaner with Advanced Air Filtration Cartridges

The activated carbon air filter cartridge is an indispensable tool in the quest for cleaner, safer air across residential, commercial, and industrial landscapes. Its unique ability to capture and neutralize gaseous pollutants and odors through adsorption makes it a cornerstone of modern air purification systems. By understanding the intricate manufacturing processes, key technical parameters, and diverse application scenarios, stakeholders can make informed decisions when selecting an air filter cartridge provider. OnlyFilterCartridge.com stands as a beacon of expertise, experience, authoritativeness, and trustworthiness, dedicated to delivering superior filter cartridge air solutions that meet the evolving demands of air quality management.

For further insights into the science and application of activated carbon in air filtration, we recommend exploring the following resources:

- Industry Forum: International Society of Indoor Air Quality and Climate (ISIAQ) - https://www.isiaq.org

- Academic Journal: Journal of Hazardous Materials - https://www.journals.elsevier.com/journal-of-hazardous-materials (Search for articles on activated carbon adsorption)

- Industry Standard: ASHRAE Handbook—HVAC Systems and Equipment (Chapter on Air Cleaners and Filters) - Consult latest edition.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: