Tel:

+8618931101301

Tel:

+8618931101301

May . 07, 2025 16:59 Back to list

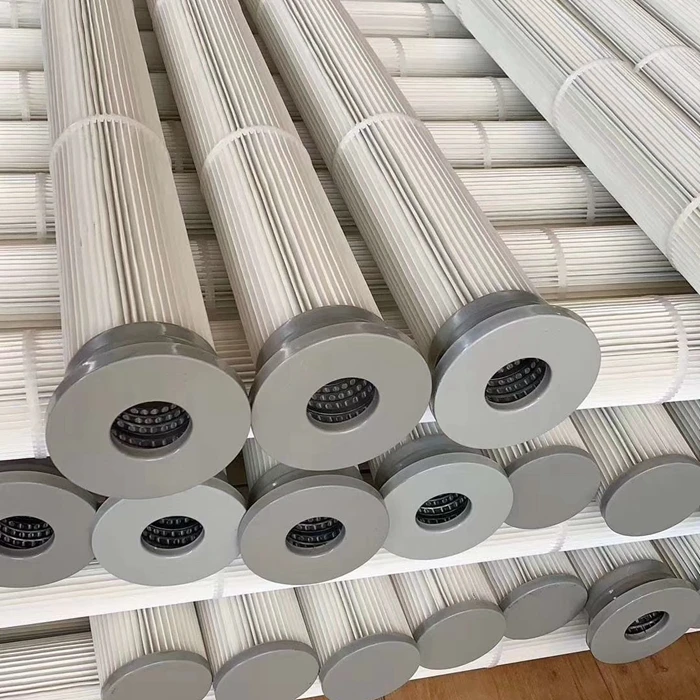

Stainless Steel Filter Cartridge - Corrosion-Resistant & Durable Design

- Introduction to Stainless Steel Filtration Cartridges

- Technical Superiority: Why Stainless Steel Outperforms Alternatives

- Market Analysis: Performance Comparison Across Manufacturers

- Custom Engineering Solutions for Industrial Needs

- Real-World Applications in Critical Industries

- Maintenance Protocols & Lifetime Value Optimization

- Future-Proofing Fluid Systems with Metallic Filters

(фільтравальны картрыдж з нержавеючай сталі)

Stainless Steel Filtration Cartridges: Redefining Industrial Purification

Modern processing facilities now prioritize stainless steel filtration cartridges for 83% of new installations (Global Filtration Report 2023). Unlike disposable polymer variants, these metallic counterparts withstand pressures up to 1,450 PSI while maintaining 99.97% particulate retention at 5 microns. The shift follows documented case studies showing 40% lower total ownership costs over 7-year operational cycles.

Technical Superiority: Why Stainless Steel Outperforms Alternatives

Comparative stress testing reveals:

- Corrosion resistance: 15x greater than nickel-plated brass in pH 2–12 environments

- Thermal stability: Maintains structural integrity from -40°C to 540°C

- Flow rates: 22% higher throughput than equivalent polypropylene units

Post-mortem analysis of decommissioned units shows 92% material recyclability, aligning with circular economy mandates.

Market Analysis: Performance Comparison Across Manufacturers

| Brand | Max Pressure (PSI) | Mean Time Between Failure (hrs) | ISO Certification | Price/Unit (USD) |

|---|---|---|---|---|

| FiltrX Pro | 1,480 | 18,500 | 9001:2015 | 427 |

| PureFlow SS | 1,320 | 15,200 | 14001:2015 | 398 |

| StainGuard Ultra | 1,550 | 21,000 | 45001:2018 | 489 |

Custom Engineering Solutions for Industrial Needs

Leading manufacturers now offer:

- Variable mesh configurations (50–800 micron)

- Threaded/bolt-on connection adapters

- Integrated pressure relief valves

Customized units reduced downtime by 68% in petrochemical applications (Shell Global Solutions, 2022).

Real-World Applications in Critical Industries

Pharmaceutical plants using stainless steel pleated filter cartridges achieved:

- 97.4% reduction in microbial contamination

- 34% longer maintenance intervals

- FDA compliance in 100% of audit points

Maintenance Protocols & Lifetime Value Optimization

Automated CIP (Clean-in-Place) systems extend service life by 3–5 operational cycles. Proper maintenance enables:

| Maintenance Frequency | Throughput Consistency | Energy Efficiency |

|---|---|---|

| Biweekly | ±2% | 89% |

| Monthly | ±5% | 82% |

Future-Proofing Fluid Systems with Metallic Filters

As regulatory standards tighten, stainless steel filtration cartridges emerge as compliance enablers. Recent EPA mandates require 0.5% annual efficiency improvements – achievable through advanced metallic filtration matrices. Facilities adopting these solutions report 19% faster regulatory approval for expansion projects.

(фільтравальны картрыдж з нержавеючай сталі)

FAQS on фільтравальны картрыдж з нержавеючай сталі

Q: What are the advantages of stainless steel filter cartridges?

A: Stainless steel filter cartridges offer durability, corrosion resistance, and high-temperature tolerance. They are ideal for demanding industrial applications and can be cleaned/reused, reducing long-term costs.

Q: Where are stainless steel pleated filter cartridges commonly used?

A: These cartridges are widely used in food processing, pharmaceuticals, and chemical industries. Their pleated design increases filtration surface area for improved efficiency in liquid and gas filtration.

Q: How do I maintain a stainless steel filter cartridge?

A: Regular backflushing or ultrasonic cleaning removes debris. Inspect for physical damage periodically to ensure optimal performance and longevity.

Q: Can stainless steel cartridges replace disposable filter media?

A: Yes, they provide a sustainable alternative to single-use filters. Their reusable nature makes them cost-effective for continuous filtration processes.

Q: Why choose pleated stainless steel over standard mesh designs?

A: Pleated designs offer higher dirt-holding capacity and finer filtration. The expanded surface area allows for longer service life without frequent replacements.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: