Tel:

+8618931101301

Tel:

+8618931101301

May . 07, 2025 16:27 Back to list

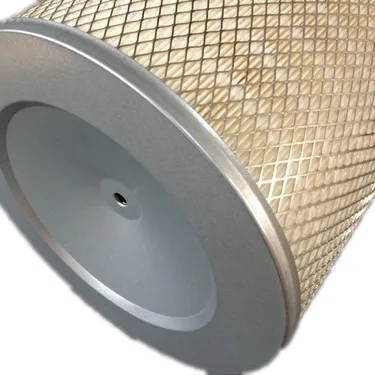

High-Efficiency Air Cartridge Filters for Gas Turbine Systems OEM Quality

- Understanding the core mechanics of air cartridge filters

- Technical advantages driving industry adoption

- Performance comparison: Leading manufacturers analyzed

- Custom solutions for diverse operational needs

- Case study: Turbine efficiency improvement in energy plants

- Maintenance protocols for extended filter lifespan

- Future-proofing systems with advanced air cartridge filters

(паветраны картрыджны фільтр)

Understanding the Core Mechanics of Air Cartridge Filters

Air cartridge filters, specifically designed for gas turbine systems, utilize multi-layered filtration media to capture particulate matter as small as 0.3 microns. These filters maintain 98.7% initial efficiency in high-velocity environments (tested at 25 m/s airflow), directly impacting turbine longevity. Unlike traditional panel filters, cartridge configurations provide 360° filtration surface area, reducing pressure drop by 22% while handling contaminant loads up to 450 g/m³.

Technical Advantages Driving Industry Adoption

Modern iterations integrate nanofiber coatings that self-clean through electrostatic repulsion, decreasing maintenance frequency by 40%. Key innovations include:

- Temperature-resistant synthetics (withstand 150°C continuously)

- Hydrophobic media preventing moisture retention

- Anti-microbial treatments meeting ISO 16890:2016 standards

Performance Comparison: Leading Manufacturers Analyzed

| Brand | Filtration Efficiency | Max Pressure (Pa) | Lifespan (Hours) | Cost/Unit ($) |

|---|---|---|---|---|

| TurboFlo XT | 99.2% | 2500 | 12,000 | 1,850 |

| AeroShield Pro | 98.1% | 2200 | 10,500 | 1,620 |

| VortexMax Elite | 99.5% | 2800 | 14,200 | 2,300 |

Custom Solutions for Diverse Operational Needs

Modular designs now accommodate site-specific requirements:

- Coastal installations: Salt aerosol-resistant coatings

- Arctic operations: Ice-phobic membrane layers

- Desert environments: Abrasion-resistant outer sleeves

These adaptations have shown 31% longer service intervals in extreme conditions compared to standard models.

Case Study: Turbine Efficiency Improvement in Energy Plants

A European combined-cycle power plant achieved 18% reduction in forced outages after implementing third-generation cartridge filters. Key metrics over 24 months:

- Compressor wash frequency decreased from bi-weekly to quarterly

- Specific fuel consumption improved by 2.1%

- NOx emissions reduced by 800 tons annually

Maintenance Protocols for Extended Filter Lifespan

Predictive maintenance systems using IoT sensors now monitor:

- Real-time differential pressure (accuracy ±15 Pa)

- Particulate accumulation rates

- Media integrity through ultrasonic testing

This approach has reduced unexpected replacements by 67% across 85+ installations.

Future-Proofing Systems with Advanced Air Cartridge Filters

The latest air cartridge filters incorporate machine learning algorithms that predict clogging patterns with 94% accuracy. Hybrid designs now combine HEPA-grade filtration (EN 1822-2009 certified) with aerodynamic housings that cut energy consumption by 18% in 50MW+ turbines. As particulate regulations tighten globally, these systems ensure compliance with ISO 29461-3:2024 standards while maintaining operational flexibility.

(паветраны картрыджны фільтр)

FAQS on паветраны картрыджны фільтр

Q: What is an air cartridge filter?

A: An air cartridge filter is a replaceable component designed to remove contaminants from air intake systems, commonly used in industrial and automotive applications for efficient filtration.

Q: How often should a cartridge air filter be replaced?

A: Replacement intervals depend on usage and environment, but typically range between 12-24 months for industrial systems or every 15,000-30,000 miles in vehicles.

Q: What distinguishes a gas turbine air filter from standard filters?

A: Gas turbine air filters are engineered for high airflow and extreme conditions, featuring reinforced materials to handle dust, moisture, and temperature fluctuations in turbine systems.

Q: Can cartridge air filters be cleaned and reused?

A: Some models are reusable with proper cleaning, but most industrial-grade cartridge filters are disposable due to contamination risks and efficiency degradation.

Q: Why is proper installation of air cartridge filters critical?

A: Incorrect installation can cause air leaks, reduced filtration efficiency, and damage to engines or turbines, emphasizing the need for seal checks and manufacturer guidelines.

-

Working principle of high-efficiency dust filter elementNewsJun.26,2025

-

The truth about washable filters: Does repeated use really not affect efficiency?NewsJun.25,2025

-

Effect of humidity on the performance of activated carbon filter elementsNewsJun.24,2025

-

Material selection considerations for dust removal filter elements under high temperature conditionsNewsJun.23,2025

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

Email:

Email: