Tel:

+8615930870079

Tel:

+8615930870079

12月 . 16, 2024 18:15 Back to list

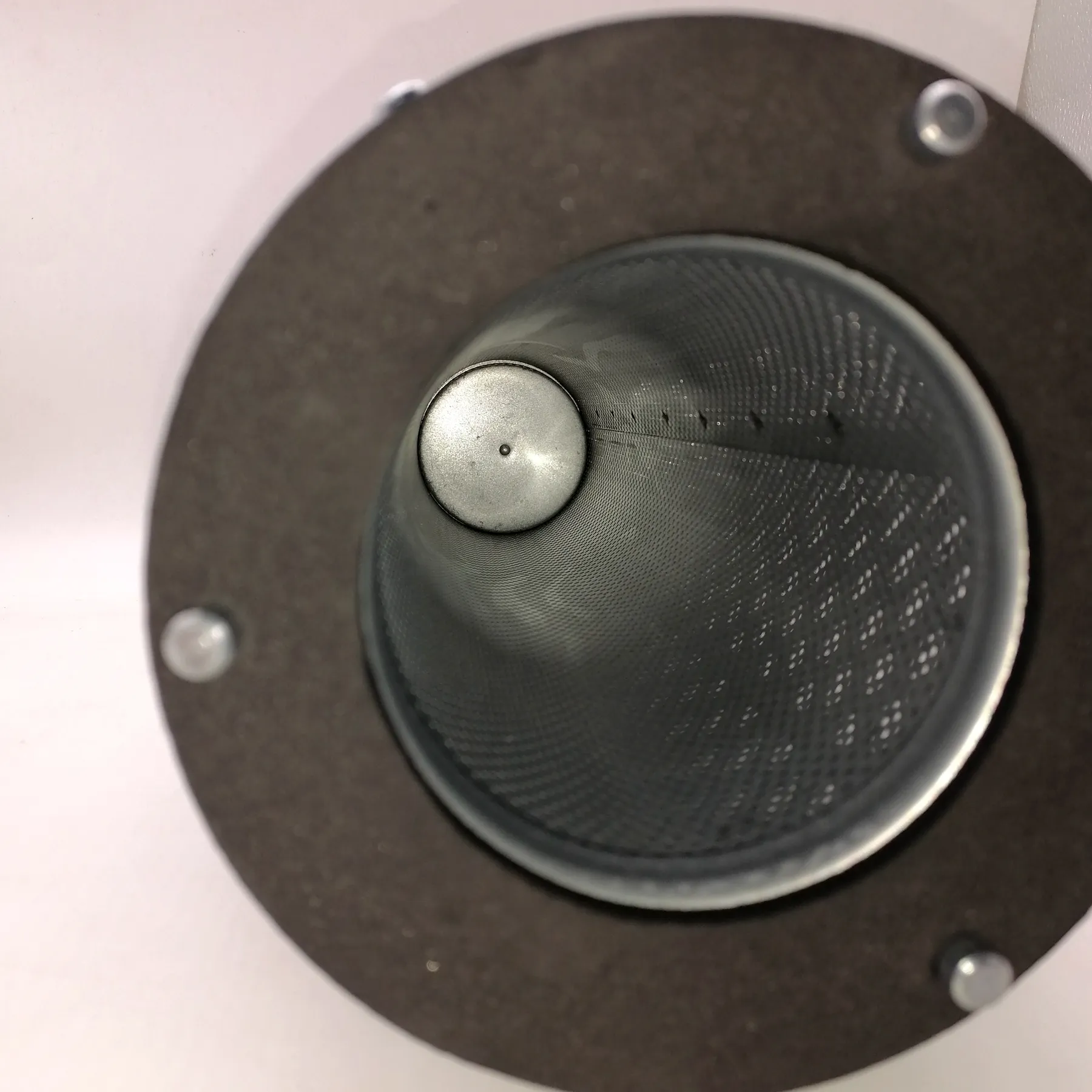

stainless steel mesh filter cartridge

Understanding Stainless Steel Mesh Filter Cartridges Features and Applications

In various industrial and commercial applications, the need for effective filtration solutions is paramount. Stainless steel mesh filter cartridges have emerged as a preferred choice due to their robust characteristics, versatility, and efficiency. These cartridges play a crucial role in ensuring the purity of fluids and gases by removing unwanted particles and contaminants.

What is a Stainless Steel Mesh Filter Cartridge?

A stainless steel mesh filter cartridge is a cylindrical device made from woven or welded stainless steel mesh. It is designed to trap and filter out solid particles from liquids or gases, thereby protecting downstream equipment and processes from potential damage caused by contaminants. Typically, these cartridges come in various micron ratings, which determine the size of particles they can effectively filter out.

Key Features of Stainless Steel Mesh Filter Cartridges

1. Durability and Strength One of the outstanding features of stainless steel is its high tensile strength and resistance to deformation. Stainless steel mesh filter cartridges can withstand extreme pressures and temperatures, making them suitable for various challenging applications.

2. Corrosion Resistance Unlike other materials, stainless steel is inherently resistant to rust and corrosion, which is crucial when filtering corrosive fluids. This characteristic extends the lifespan of the filter cartridge, resulting in fewer replacements and lower operational costs.

3. Easy Maintenance and Cleaning Stainless steel mesh filters can be cleaned and reused, a significant advantage over disposable filters. They can often be backwashed or cleaned with solvents, eliminating operational downtime associated with frequent filter changes.

4. Versatility Stainless steel mesh filter cartridges are used in a wide range of applications, including water treatment, oil and gas industries, pharmaceuticals, and food and beverage processing. Their ability to filter different substances makes them an adaptable solution across various sectors.

stainless steel mesh filter cartridge

5. Customizable Designs Manufacturers often provide custom options to fit specific requirements. Various mesh sizes, shapes, and filter configurations can be tailored to meet unique filtration needs, enhancing their effectiveness in specific applications.

Applications of Stainless Steel Mesh Filter Cartridges

1. Water Treatment These cartridges are widely used in municipal and industrial water treatment facilities to remove sediment and particulate matter, ensuring the production of clean water for consumption or further processing.

2. Chemical Processing In chemical industries, maintaining purity is vital. Stainless steel mesh filter cartridges help in filtering out contaminants from solvents, acids, and other chemicals critical to maintaining quality and safety.

3. Petroleum and Oil Filtration In the oil and gas sector, stainless steel mesh filters are utilized to remove debris from crude oil and natural gas. Their ability to tolerate harsh environments makes them ideal for upstream and downstream applications.

4. Pharmaceuticals and Food Industry Ensuring product purity in the pharmaceutical and food sectors is non-negotiable. Stainless steel mesh filter cartridges help in the filtration of various fluids to prevent contamination and ensure compliance with health regulations.

Conclusion

Stainless steel mesh filter cartridges are an invaluable asset in a myriad of industries due to their durability, corrosion resistance, and ability to maintain high filtration standards. As industries continue to evolve and the demand for quality and efficiency rises, these filter cartridges will remain at the forefront of filtration technology. Their effectiveness and adaptability ensure that they not only meet current needs but also adapt to future challenges in filtration processes. Investing in stainless steel mesh filter cartridges is not just a choice for immediate filtration needs but a long-term solution that contributes to operational efficiency and cost savings.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: