電話:

+8615930870079

電話:

+8615930870079

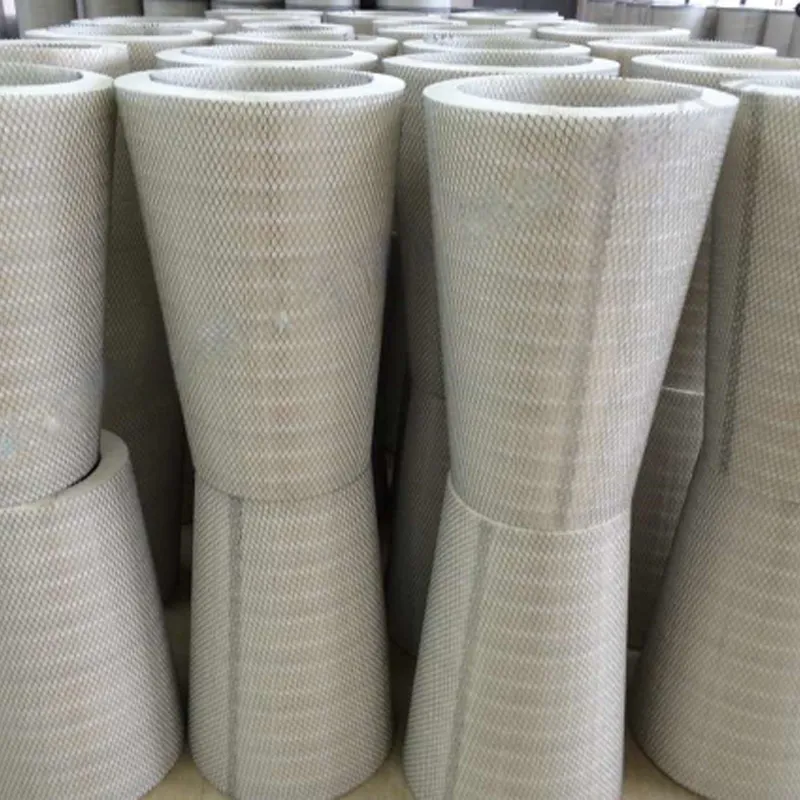

ガスタービン吸気フィルター

製品説明: ガスタービンフィルターカートリッジは、ガスタービン専用に設計された高効率ろ過装置です。主な機能は、ガスタービン燃焼システムに入る空気中の不純物や粒子状物質を除去し、これらの汚染物質がガスタービンのタービンブレードや燃焼器に摩耗や損傷を引き起こすのを防ぎ、ガスタービンの効率的な動作と長期安定性を確保することです。

ガスタービン フィルター カートリッジには通常、ポリエステルやグラスファイバーなどの高度な合成繊維材料が使用されています。これらの材料は、強度、耐高温性、耐腐食性、優れた濾過性能を備えています。フィルター カートリッジの設計には通常、複数の層のフィルター メディアが含まれ、各層は異なる孔サイズを持ち、大きなものから小さなものまで段階的な濾過効果を実現します。これにより、きれいな空気を通過させながら、小さな粒子も効果的に捕捉できます。

ガスタービンのさまざまな作業条件のニーズに適応するために、フィルターカートリッジには、吸気温度、圧力、流量の変化に適応するための一定の弾性と圧縮性もあります。また、フィルターカートリッジのシールと取り付け方法も慎重に設計されており、高圧および高温環境で漏れが発生しないようにします。

ガスタービン フィルター カートリッジを選択するときは、ガスタービンのモデル、動作条件、必要なろ過精度を考慮する必要があります。適切なフィルター カートリッジを選択すると、ガスタービンの効率が向上するだけでなく、耐用年数が延び、メンテナンス コストも削減されます。

つまり、ガスタービンフィルターカートリッジは、ガスタービンの正常な動作のための重要なコンポーネントの 1 つであり、効率的なろ過性能を通じてガスタービン燃焼システムの清浄度と安全性を確保し、ガスタービンの全体的な性能と信頼性を向上させる上で重要な役割を果たします。

Gas Turbine Intake Filters: The Unsung Hero of Turbine Longevity

In the high-stakes world of power generation and industrial energy, gas turbines are the workhorses that drive productivity—but their longevity depends on a component often overlooked: the gas turbine air intake filter. As a leading gas turbine air intake filter manufacturer, ONLY TECHNOLOGY understands that these filters are the unsung heroes, silently safeguarding turbines from the contaminants that threaten their performance and lifespan.

At the core of this protection is the gas turbine filter’s ability to intercept harmful particles. Turbines operate in harsh environments, exposed to dust, sand, salt, and industrial debris—each capable of causing catastrophic damage. A high-quality gas turbine air filter traps particles as small as 1 micron, preventing them from entering the turbine’s combustion chamber and turbine blades. Over time, unfiltered particles cause erosion, corrosion, and fouling, which reduce efficiency by up to 20% and force premature overhauls. Our filters act as a first line of defense, ensuring only clean air reaches critical components.

The design of turbine air intake filters is engineered for durability, a trait that directly impacts turbine longevity. Crafted with multi-layered media—including hydrophobic materials to repel moisture and synthetic fibers for high dust-holding capacity—these filters withstand extreme temperatures, humidity, and pressure fluctuations. Unlike generic filters that degrade quickly, our gas turbine air intake filter maintains integrity for 6–12 months in heavy-duty operations, reducing the frequency of replacements that disrupt turbine runtime.

Efficiency in airflow is another key role these filters play. A well-designed gas turbine air filter balances filtration precision with low airflow resistance, ensuring the turbine receives the high-volume air it needs for optimal combustion. Restricted airflow strains the turbine, increasing fuel consumption and wear on internal parts. Our filters, optimized for minimal pressure drop, preserve airflow efficiency, allowing turbines to operate at peak performance while staying protected—extending their service life by years.

As a dedicated gas turbine air intake filter manufacturer, we tailor solutions to specific environments. Coastal turbines facing salt spray benefit from anti-corrosive turbine air intake filters, while desert installations use specialized media to block fine sand. This customization ensures targeted protection, addressing the unique threats in each location and further enhancing turbine durability.

In essence, gas turbine air intake filter systems are the guardians of turbine longevity. They may not command attention like the turbines themselves, but their role in preventing damage, maintaining efficiency, and reducing downtime is irreplaceable. At ONLY TECHNOLOGY, we craft these unsung heroes to the highest standards, ensuring that every gas turbine filter contributes to the long, reliable service of the turbines that power our world.

|

モデル |

仕様 |

処理空気量 |

小さな穴の取り付け |

初期の抵抗 |

フィルターエリア |

フィルタリング効率 |

|

AR-ON3266 |

406/360Xφ324X660 |

1000m3/時 |

φ14 |

120〜150Pa |

22.3㎡ |

99.99% |

|

AR-ON3266 |

φ445Xφ324X660 |

900m3/時 |

φ14 |

120〜150Pa |

25㎡ |

99.99% |

標準外の製品カスタマイズも承ります。

適用範囲:GE、SOLAR、SIEMENS、ALSTOM、MITSUBISHIなどのガスタービンコンプレッサー入口ろ過、発電機換気ろ過などに使用できます。

From Dust to Durability: How Gas Turbine Intake Filters Transform Performance

In the world of industrial power, the journey from unfiltered air—laden with dust, grit, and contaminants—to a turbine’s long-term durability is guided by a critical component: the gas turbine air intake filter. As a leading gas turbine air intake filter manufacturer, ONLY TECHNOLOGY understands that these filters do more than clean air—they transform turbine performance, turning potential damage into sustained efficiency and longevity.

Dust and particulate matter are turbine enemies. When unfiltered, even micron-sized particles erode compressor blades, clog cooling channels, and degrade combustion efficiency, leading to increased fuel consumption, frequent breakdowns, and shortened lifespans. This is where the gas turbine filter steps in. Engineered to trap particles as small as 0.3 microns, it acts as a barrier, preventing abrasive contaminants from entering the turbine’s core. By stopping dust at the intake, the gas turbine air filter eliminates the root cause of wear, preserving critical components and maintaining optimal airflow— the first step in transforming vulnerability into resilience.

The design of turbine air intake filters amplifies this transformation. Multi-layered filtration media, combining synthetic fibers and hydrophobic materials, ensures high dust-holding capacity while resisting moisture and corrosion. This means the filter remains effective even in harsh environments—whether desert dust storms, coastal salt spray, or industrial emissions. Unlike basic filters that saturate quickly, our gas turbine air intake filter maintains performance for 6–12 months under heavy use, reducing downtime and keeping turbines operating at peak levels. This consistency turns sporadic performance into reliable output.

Efficiency is another key transformation. A clogged or inefficient filter restricts airflow, forcing turbines to work harder and burn more fuel. Our gas turbine air filter, optimized for low pressure drop, balances strict filtration with unobstructed airflow. This harmony ensures the turbine receives the volume of clean air needed for efficient combustion, cutting fuel costs by up to 5% and lowering emissions. What starts as a battle against dust becomes a boost in operational efficiency, driving both performance and sustainability.

As a dedicated gas turbine air intake filter manufacturer, we tailor solutions to specific challenges. Coastal turbines get turbine air intake filters with anti-salt coatings, while industrial settings use high-temperature media to combat chemical particles. This customization ensures the gas turbine filter addresses unique contaminants, turning generic protection into targeted defense.

In essence, gas turbine air intake filter systems bridge the gap between harmful dust and turbine durability. They transform the threat of wear into long-term reliability, the inefficiency of restricted airflow into smooth operation, and generic filtration into precision performance. At ONLY TECHNOLOGY, every gas turbine air filter is engineered to make this transformation possible—proving that when it comes to turbine performance, the right filter doesn’t just filter—it transforms.

メッセージを残す

Eメール:

Eメール: