هاتف:

+8615930870079

هاتف:

+8615930870079

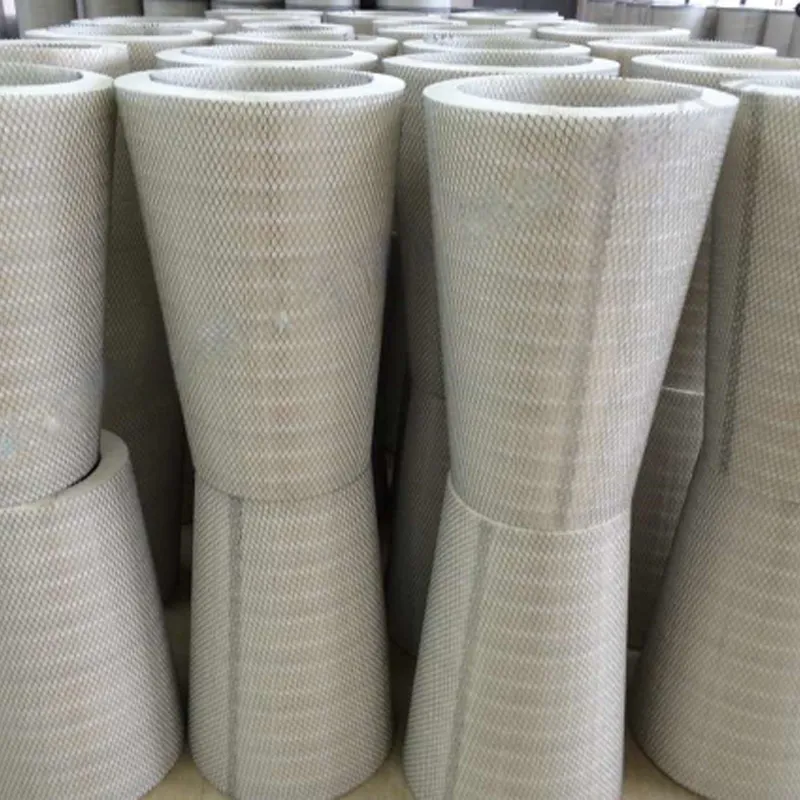

مرشح مدخل توربينات الغاز

وصف المنتج: خرطوشة فلتر توربينات الغاز عبارة عن معدات ترشيح عالية الكفاءة مصممة خصيصًا لتوربينات الغاز. وتتمثل وظيفتها الرئيسية في إزالة الشوائب والجسيمات الموجودة في الهواء الداخل إلى نظام احتراق توربينات الغاز لمنع هذه الملوثات من التسبب في تآكل شفرات التوربينات واحتراق توربينات الغاز. والأضرار، وبالتالي ضمان التشغيل الفعال والاستقرار على المدى الطويل لتوربينات الغاز.

تستخدم خراطيش فلتر توربينات الغاز عادةً مواد ألياف صناعية متقدمة، مثل البوليستر أو الألياف الزجاجية، والتي تتميز بقوة عالية ومقاومة درجات الحرارة العالية ومقاومة التآكل وأداء ترشيح جيد. يتضمن تصميم خرطوشة الفلتر عادةً طبقات متعددة من وسائط الفلتر، كل طبقة لها حجم مسام مختلف، لتحقيق تأثير الترشيح خطوة بخطوة من الأكبر إلى الأصغر. وهذا يضمن التقاط حتى الجزيئات الصغيرة بشكل فعال مع السماح للهواء النظيف بالمرور من خلالها.

من أجل التكيف مع احتياجات توربينات الغاز في ظل ظروف عمل مختلفة، تتمتع خرطوشة الفلتر أيضًا بدرجة معينة من المرونة والانضغاط للتكيف مع التغيرات في درجة حرارة الهواء الداخل والضغط والتدفق. بالإضافة إلى ذلك، تم أيضًا تصميم طرق الختم والتركيب لخرطوشة الفلتر بعناية لضمان عدم حدوث تسرب في البيئات ذات الضغط العالي ودرجات الحرارة العالية.

عند اختيار خرطوشة فلتر توربينات الغاز، عليك أن تأخذ بعين الاعتبار نموذج توربينات الغاز، وظروف التشغيل، ودقة الترشيح المطلوبة. لا يمكن لخرطوشة الفلتر الصحيحة تحسين كفاءة توربينات الغاز فحسب، بل يمكنها أيضًا إطالة عمر الخدمة وتقليل تكاليف الصيانة.

باختصار، تعد خرطوشة فلتر توربينات الغاز أحد المكونات الرئيسية للتشغيل العادي لتوربينات الغاز. إنه يضمن نظافة وسلامة نظام احتراق توربينات الغاز من خلال أداء الترشيح الفعال، ويلعب دورًا حيويًا في تحسين الأداء العام وموثوقية توربينات الغاز.

Gas Turbine Intake Filters: The Unsung Hero of Turbine Longevity

In the high-stakes world of power generation and industrial energy, gas turbines are the workhorses that drive productivity—but their longevity depends on a component often overlooked: the gas turbine air intake filter. As a leading gas turbine air intake filter manufacturer, ONLY TECHNOLOGY understands that these filters are the unsung heroes, silently safeguarding turbines from the contaminants that threaten their performance and lifespan.

At the core of this protection is the gas turbine filter’s ability to intercept harmful particles. Turbines operate in harsh environments, exposed to dust, sand, salt, and industrial debris—each capable of causing catastrophic damage. A high-quality gas turbine air filter traps particles as small as 1 micron, preventing them from entering the turbine’s combustion chamber and turbine blades. Over time, unfiltered particles cause erosion, corrosion, and fouling, which reduce efficiency by up to 20% and force premature overhauls. Our filters act as a first line of defense, ensuring only clean air reaches critical components.

The design of turbine air intake filters is engineered for durability, a trait that directly impacts turbine longevity. Crafted with multi-layered media—including hydrophobic materials to repel moisture and synthetic fibers for high dust-holding capacity—these filters withstand extreme temperatures, humidity, and pressure fluctuations. Unlike generic filters that degrade quickly, our gas turbine air intake filter maintains integrity for 6–12 months in heavy-duty operations, reducing the frequency of replacements that disrupt turbine runtime.

Efficiency in airflow is another key role these filters play. A well-designed gas turbine air filter balances filtration precision with low airflow resistance, ensuring the turbine receives the high-volume air it needs for optimal combustion. Restricted airflow strains the turbine, increasing fuel consumption and wear on internal parts. Our filters, optimized for minimal pressure drop, preserve airflow efficiency, allowing turbines to operate at peak performance while staying protected—extending their service life by years.

As a dedicated gas turbine air intake filter manufacturer, we tailor solutions to specific environments. Coastal turbines facing salt spray benefit from anti-corrosive turbine air intake filters, while desert installations use specialized media to block fine sand. This customization ensures targeted protection, addressing the unique threats in each location and further enhancing turbine durability.

In essence, gas turbine air intake filter systems are the guardians of turbine longevity. They may not command attention like the turbines themselves, but their role in preventing damage, maintaining efficiency, and reducing downtime is irreplaceable. At ONLY TECHNOLOGY, we craft these unsung heroes to the highest standards, ensuring that every gas turbine filter contributes to the long, reliable service of the turbines that power our world.

|

نموذج |

تحديد |

معالجة حجم الهواء |

تركيب الثقوب الصغيرة |

المقاومة الأولية |

منطقة التصفية |

كفاءة التصفية |

|

AR-ON3266 |

406/360Xφ324X660 |

1000 م 3 / ساعة |

φ14 |

120 ~ 150 باسكال |

22.3m2 |

99.99% |

|

AR-ON3266 |

φ445Xφ324X660 |

900 م 3 / ساعة |

φ14 |

120 ~ 150 باسكال |

25 m2 |

99.99% |

قبول تخصيص المنتج غير القياسي.

نطاق التطبيق: يمكن استخدامه في ترشيح مدخل ضاغط توربينات الغاز، وترشيح تهوية المولدات، وما إلى ذلك لشركة GE، وSOLAR، وSIEMENS، وALSTOM، وMITSUBISHI، وما إلى ذلك.

From Dust to Durability: How Gas Turbine Intake Filters Transform Performance

In the world of industrial power, the journey from unfiltered air—laden with dust, grit, and contaminants—to a turbine’s long-term durability is guided by a critical component: the gas turbine air intake filter. As a leading gas turbine air intake filter manufacturer, ONLY TECHNOLOGY understands that these filters do more than clean air—they transform turbine performance, turning potential damage into sustained efficiency and longevity.

Dust and particulate matter are turbine enemies. When unfiltered, even micron-sized particles erode compressor blades, clog cooling channels, and degrade combustion efficiency, leading to increased fuel consumption, frequent breakdowns, and shortened lifespans. This is where the gas turbine filter steps in. Engineered to trap particles as small as 0.3 microns, it acts as a barrier, preventing abrasive contaminants from entering the turbine’s core. By stopping dust at the intake, the gas turbine air filter eliminates the root cause of wear, preserving critical components and maintaining optimal airflow— the first step in transforming vulnerability into resilience.

The design of turbine air intake filters amplifies this transformation. Multi-layered filtration media, combining synthetic fibers and hydrophobic materials, ensures high dust-holding capacity while resisting moisture and corrosion. This means the filter remains effective even in harsh environments—whether desert dust storms, coastal salt spray, or industrial emissions. Unlike basic filters that saturate quickly, our gas turbine air intake filter maintains performance for 6–12 months under heavy use, reducing downtime and keeping turbines operating at peak levels. This consistency turns sporadic performance into reliable output.

Efficiency is another key transformation. A clogged or inefficient filter restricts airflow, forcing turbines to work harder and burn more fuel. Our gas turbine air filter, optimized for low pressure drop, balances strict filtration with unobstructed airflow. This harmony ensures the turbine receives the volume of clean air needed for efficient combustion, cutting fuel costs by up to 5% and lowering emissions. What starts as a battle against dust becomes a boost in operational efficiency, driving both performance and sustainability.

As a dedicated gas turbine air intake filter manufacturer, we tailor solutions to specific challenges. Coastal turbines get turbine air intake filters with anti-salt coatings, while industrial settings use high-temperature media to combat chemical particles. This customization ensures the gas turbine filter addresses unique contaminants, turning generic protection into targeted defense.

In essence, gas turbine air intake filter systems bridge the gap between harmful dust and turbine durability. They transform the threat of wear into long-term reliability, the inefficiency of restricted airflow into smooth operation, and generic filtration into precision performance. At ONLY TECHNOLOGY, every gas turbine air filter is engineered to make this transformation possible—proving that when it comes to turbine performance, the right filter doesn’t just filter—it transforms.

اترك رسالتك

بريد إلكتروني:

بريد إلكتروني: