Tel:

+8615930870079

Tel:

+8615930870079

11月 . 24, 2024 15:40 Back to list

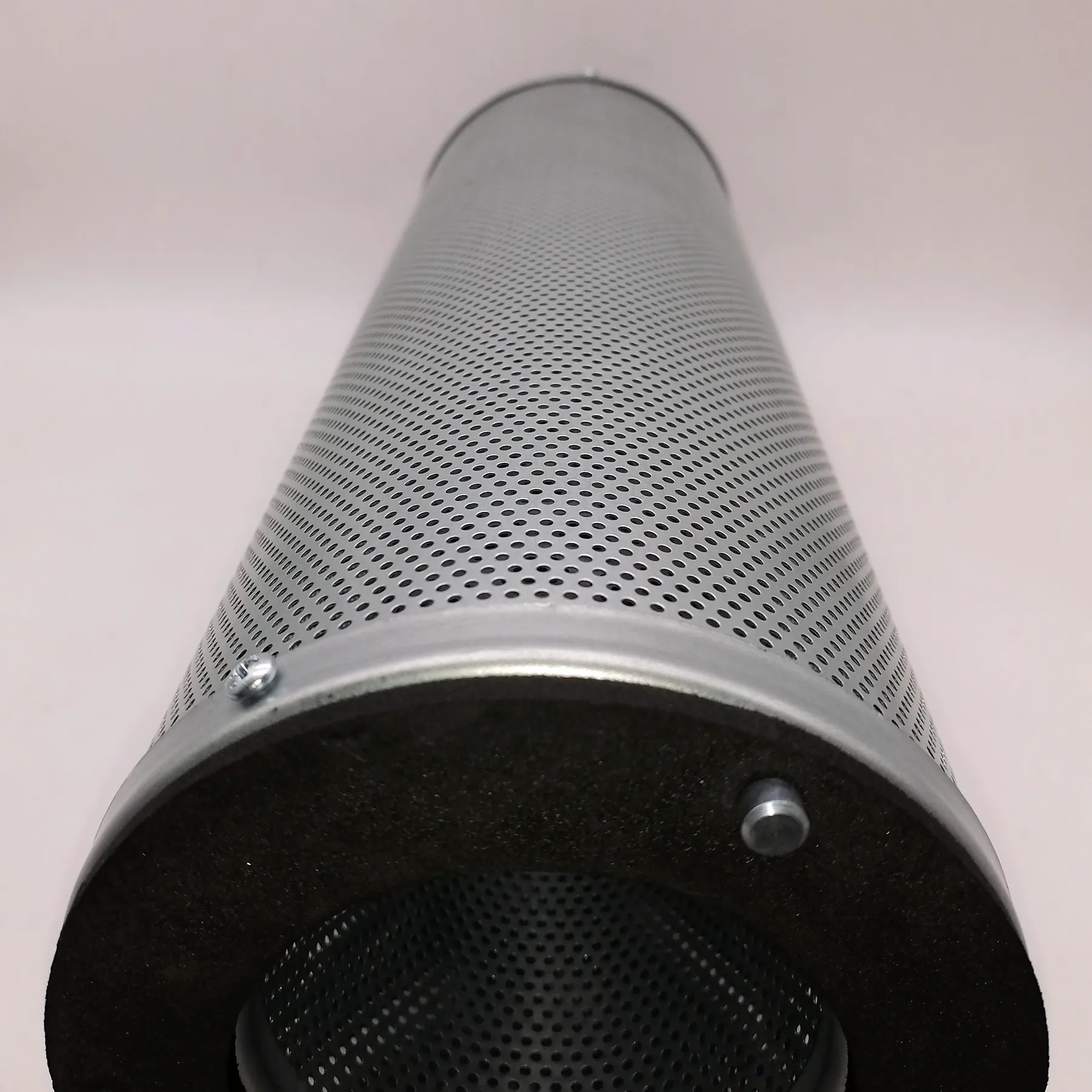

pleated polyester filter cartridge

The Importance of Pleated Polyester Filter Cartridges in Modern Filtration Technology

In today's rapidly evolving industrial landscape, efficient filtration systems have become essential for maintaining product quality, ensuring safety, and protecting equipment. Among the various types of filter cartridges available, pleated polyester filter cartridges have gained significant popularity due to their superior performance and versatility. This article explores the characteristics, benefits, and applications of pleated polyester filter cartridges, highlighting their crucial role in modern filtration technology.

What is a Pleated Polyester Filter Cartridge?

A pleated polyester filter cartridge consists of a series of folds or pleats made from high-quality polyester material, which increases the surface area of the filter media. This design enhances the filtration capacity, allowing for the effective removal of particulate matter while maintaining a high flow rate. By utilizing polyester, these cartridges can withstand various chemical environments, making them suitable for multiple applications across different industries.

Key Features

1. High Dirt Holding Capacity The pleated design significantly increases the filter’s surface area, allowing it to capture more contaminants before becoming saturated. This characteristic leads to longer service life and reduced maintenance frequency.

2. Chemical Compatibility Polyester is known for its excellent chemical resistance, making pleated polyester filter cartridges suitable for filtering various fluids, including those containing chemicals, oils, and solvents.

3. Temperature Resistance These cartridges can operate effectively in a range of temperatures, making them ideal for both hot and cold processes.

4. Easy Installation and Replacement Pleated polyester filter cartridges are designed for user-friendly installation, and replacing them is straightforward, minimizing downtime during routine maintenance.

5. Cost-Effectiveness With their durability and extended lifespan, pleated polyester filter cartridges can provide significant cost savings over time, reducing the need for frequent replacements.

Benefits of Using Pleated Polyester Filter Cartridges

The adoption of pleated polyester filter cartridges offers several advantages to industries reliant on effective filtration systems

1. Improved Efficiency The high dirt holding capacity ensures that these filters can operate efficiently, providing consistent filtration performance even in demanding conditions. This reliability translates to less downtime and greater productivity.

pleated polyester filter cartridge

2. Enhanced Product Quality In applications where the purity of the final product is crucial, such as food and beverage manufacturing or pharmaceuticals, pleated polyester filter cartridges help maintain high standards by removing contaminants that could compromise quality.

3. Environmental Protection By ensuring the clarity and quality of effluents, these filter cartridges play a role in protecting the environment. They help industries comply with regulatory standards regarding wastewater discharge.

4. Versatility Pleated polyester filter cartridges are suitable for various applications, including water treatment, chemical processing, and industrial fluid filtration. Their adaptability makes them a preferred choice across multiple sectors.

Applications

Pleated polyester filter cartridges find applications in numerous industries, including

- Water Treatment In municipal water treatment plants, these filters effectively remove sediments and particulate matter, ensuring clean water supply for communities.

- Food and Beverage The food industry relies on these cartridges to ensure the safety and quality of products, filtering out unwanted particles from beverages, juices, and other consumables.

- Pharmaceuticals In the pharmaceutical realm, maintaining sterility and product purity is vital. Pleated polyester filters help achieve the necessary standards for drug manufacturing.

- Oil and Gas These filters can withstand harsh conditions and are used to refine oils and process fluids, enhancing product quality while protecting equipment.

- Manufacturing Processes Various manufacturing industries utilize pleated polyester filters to maintain equipment efficiency and product quality, filtering out debris and contaminants during production.

Conclusion

In conclusion, pleated polyester filter cartridges represent a significant advancement in filtration technology. Their high dirt holding capacity, chemical compatibility, and cost-effectiveness make them essential for a wide range of applications across various industries. As the demand for efficient and reliable filtration solutions continues to grow, pleated polyester filter cartridges will undoubtedly play a pivotal role in meeting these challenges, ensuring product quality, equipment longevity, and environmental protection. Investing in these innovative filters is not just a choice; it is a step towards operational excellence and sustainability in today's industrial environment.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: