Tel:

+8615930870079

Tel:

+8615930870079

12月 . 03, 2024 16:49 Back to list

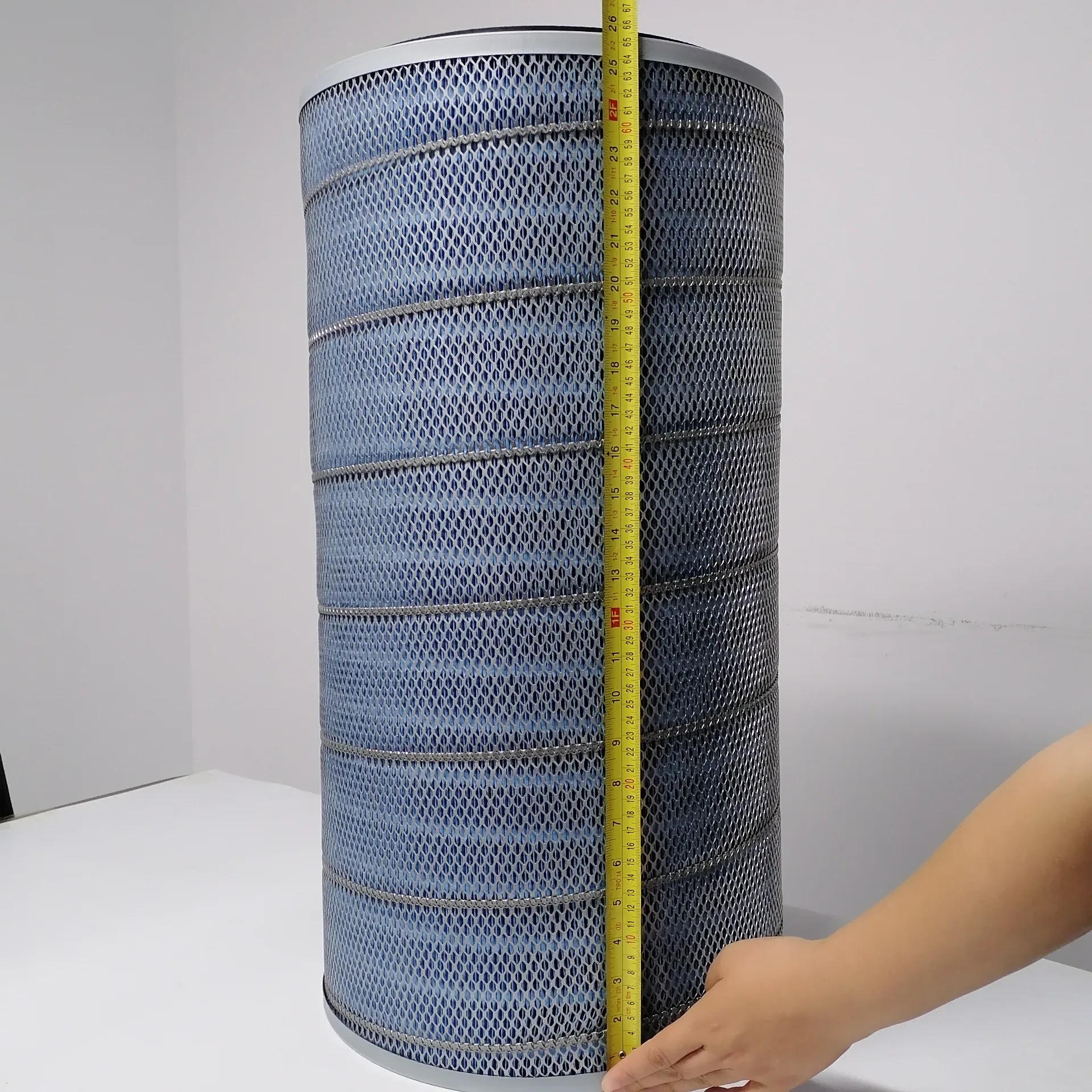

gas turbine air intake filter

The Importance of Air Intake Filters in Gas Turbines

Gas turbines have established themselves as a fundamental pillar in the generation of power and propulsion in various industries. These machines, which convert the energy from fuel into mechanical energy, rely heavily on a consistent supply of clean air. The air intake system plays a crucial role in this process, and at its heart lies the air intake filter. This article explores the significance of air intake filters for gas turbines, their operation, and their impact on performance and maintenance.

Understanding the Air Intake Process

Before diving into the specifics of air intake filters, it is essential to grasp their role within the gas turbine's operation. Gas turbines extract energy from burning fuel within a compressed air environment. While it may seem straightforward, the quality of the air entering the turbine is paramount for optimal performance. Contaminants such as dust, dirt, salt, and other particulates can severely impair the functioning of the turbine, leading to inefficiencies and potential damage.

The Role of Air Intake Filters

Air intake filters serve as the first line of defense against these contaminants. Positioned strategically at the air intake, these filters are designed to capture particles before they enter the turbine, ensuring that only clean air reaches the combustion chamber. The efficiency of these filters directly correlates with the turbine's efficiency; thus, their proper selection and maintenance are critical.

Various types of air filters are commonly used in gas turbines, including panel filters, bag filters, and pleated filters. The choice of filter depends on several factors, including the environment in which the turbine operates, the size of the particulate matter, and the specific design of the turbine.

Efficiency and Performance

gas turbine air intake filter

The efficiency of gas turbines can be significantly impacted by the condition of the air intake filter. A clean filter allows for optimal airflow, which is essential for maintaining the right pressure and temperature within the combustion chamber. When filters are clogged or dirty, they reduce airflow, leading to a drop in performance. This can manifest as reduced power output, increased fuel consumption, and higher emissions.

Moreover, the presence of harmful particulates can lead to excessive wear on turbine components, contributing to increased maintenance costs and downtime. Consequently, regular monitoring and timely replacement of air intake filters are vital practices for operators aiming to ensure the longevity and efficiency of their gas turbines.

Maintenance Best Practices

To maximize the effectiveness of air intake filters in gas turbines, operators should adhere to several best practices. First, establishing a scheduled maintenance routine is essential. This includes regularly checking the condition of the filters, cleaning or replacing them as necessary based on operational environments and loading conditions. Operators should refer to specific guidelines from the turbine manufacturer regarding filter replacement intervals.

Second, utilizing advanced filtration technologies can enhance the filtration efficiency. HEPA (High-Efficiency Particulate Air) filters and synthetic media filters provide superior protection against smaller particles that standard filters may miss. By investing in higher-quality filters, operators can further safeguard their turbines from contaminants.

Additionally, monitoring systems can be implemented to gauge the pressure drop across the filters. A noticeable increase in pressure drop indicates a buildup of dirt and debris, prompting timely action before efficiency suffers.

Conclusion

In the world of gas turbines, air intake filters may often be overlooked in the grand scheme of operations. However, their importance cannot be overstated. A reliable air intake filter system is integral to maintaining turbine efficiency, optimizing performance, and prolonging equipment lifespan. By implementing regular maintenance practices, utilizing advanced filtration technologies, and monitoring filter conditions, operators can ensure their gas turbines operate at peak efficiency while minimizing risks associated with air quality. In an era where efficiency and sustainability are paramount, prioritizing the health of air intake filters is a step every gas turbine operator should take.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: