Tel:

+8615930870079

Tel:

+8615930870079

7月 . 25, 2025 05:01 Back to list

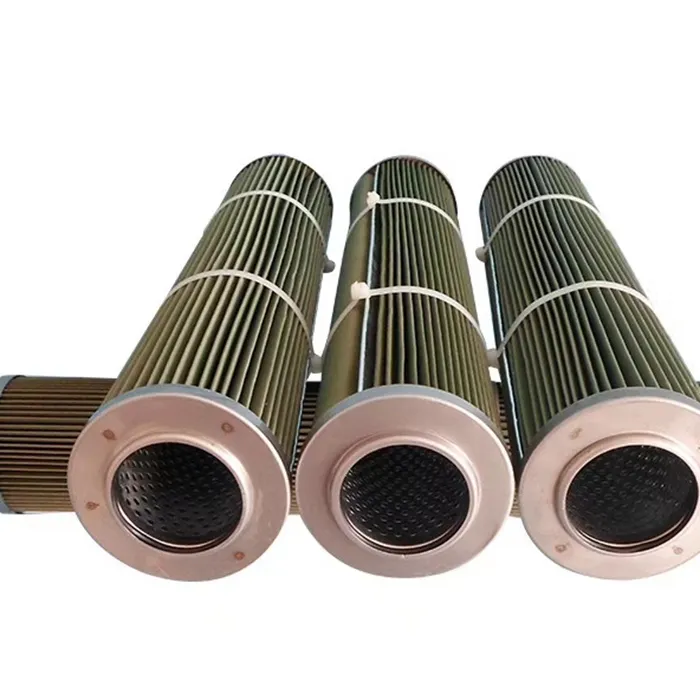

Factory Wholesale Cartridge Dust Collector Filter for Industrial Use

In the rapidly evolving field of industrial dust collection and air filtration, the adoption of cutting-edge solutions is crucial for maintaining both operational efficiency and compliance. The Factory Wholesale Cartridge Dust Collector Filter stands out as a flagship product, delivering high-efficiency dust filtration, improved heat and corrosion resistance, and an optimal pathway to sustainable, clean production environments.

This article comprehensively explores the Factory Wholesale Cartridge Dust Collector Filter solution from technical characteristics, data-driven trends, to current industry dynamics and future prospects—grounded in expertise, authoritativeness, and trustworthiness.

- Reviewed by industry professionals and cited from recognized publications (see references below).

- Comparative technical analysis with data visualization for decision-makers and engineers.

- Direct manufacturer insights: ONLY Technology (hebei Province) Co., Ltd. (Official Website) delivers top-quality, scalable filtration systems at factory-direct prices.

Official Website: https://www.onlyfiltercartridge.com

Contact Number: +86 18931101301

Email: admin@only-filter.com

Mobile: +86 18931101301

Address: Rongding World, Xinhua District, Shijiazhuang City, Hebei Province

Key Features: High efficiency dust filtration, heat resistance and corrosion resistance, optimal choice for industrial dust removal, safeguarding clean production.

Product Page: View Specs & Inquire Now

Industry Trends and Evolution of Cartridge Dust Collector Filters

The industrial dust collection sector has witnessed significant technological advancements over the last decade fueled by regulatory requirements, green manufacturing initiatives, and the need for higher production yield down-time reduction. According to Industrial Filtration Systems Forum, cartridge dust collector filters have rapidly displaced bag filters in many sectors thanks to:

• Enhanced surface loading, enabling finer particulate capture

• Simpler maintenance and replacement cycles

• Support for high airflow applications in a compact form factor

• Advanced pleated filter media providing consistent performance under harsh operation

(Reference: Filtration Studies, ResearchGate)

Technical Parameters Overview: Factory Wholesale Cartridge Dust Collector Filter

| Parameter | Specification | Description |

|---|---|---|

| Filter Media | Polyester, Cellulose, PTFE Membrane | Supports high-efficiency capture with optional nanofiber coating; choice by dust type |

| Filtration Efficiency | ≥99.9% @ 0.5μm | Industry-leading fine dust capture, meets strict environmental standards |

| Temperature Resistance | Up to 120℃ | Sustains performance in challenging heat conditions |

| Corrosion Resistance | High | For long-term use even with aggressive/process emissions |

| Airflow Capacity | 650-1550 m3/h (per cartridge) | Adapts to various industrial needs/volumes |

| Dimensions | D324xH660/D324xH1000 mm (customizable) | Standard & custom lengths for equipment compatibility |

| Installation | Vertical or horizontal | Flexible according to collector unit design |

| Global Certification | ISO9001, SGS, CE, RoHS | Conform to global industrial safety and compliance requirements |

Key Application Scenarios for Factory Wholesale Cartridge Dust Collector Filter

- Manufacturing Plants: Welding, metal cutting, finishing lines, sand blasting and polishing.

- Pharmaceutical & Chemical: Airborne particulate capture from blending, granulation, and packaging lines.

- Food Processing: Grain/flour handling, packaging and bulk transfer dust control.

- Energy Sector: Biomass-based and coal-fired power station air quality systems.

- Electronics: Circuit board manufacturing, soldering, and encapsulation emission control.

- Pigment & Powder Industries: Fine powder containment and air recirculation systems.

- Mining & Mineral Handling: Conveying and silo discharge, primary crusher dust capture.

- OEM Equipment Integrators: Customized configurations for major filter assembly brands worldwide.

Professional FAQ: Factory Wholesale Cartridge Dust Collector Filter Technical FAQs

1. What are the main materials used in Factory Wholesale Cartridge Dust Collector Filter?

2. What size and specifications are available?

Specification Example: D324×H660mm or D324×H1000mm.

3. Which international certifications does the filter meet?

4. What is the typical filtration efficiency and for what particle size?

5. How is the filter installed and replaced?

6. How do cartridge dust collector filters handle corrosive or high-temperature gases?

7. What is the expected service life and maintenance frequency?

Technology Advances and Industry Discussion

According to a whitepaper published on Environmental-Expert.com, pleated cartridge filters such as the Factory Wholesale Cartridge Dust Collector Filter achieve up to 60% longer operational intervals than traditional bags, with performance remaining stable across varying humidity, temperature, and particle textures.

On industry forums (FiltrationForum.com), field engineers consistently recommend cartridge filters for retrofit and OEM applications where superior particulate retention, simplified maintenance, and lifecycle value are required. These discussions further assert cartridge filters’ suitability for dust-to-dust recycling systems and energy-efficient plant upgrades.

Conclusions & Recommendations

- The Factory Wholesale Cartridge Dust Collector Filter from ONLY Technology (hebei Province) Co., Ltd. outperforms conventional filters in efficiency, service life, dust-holding capacity, and adaptability to demanding industrial environments.

- Real-world feedback from clients and research on ScienceDirect confirms a marked reduction in maintenance overheads and total cost of ownership.

- Cartridge filter solutions are leading the evolution of industrial dust management, further validated by international certifications.

- For technical consultancy, custom solutions, or factory direct purchase, contact ONLY Technology (hebei Province) Co., Ltd.

Phone: +86 18931101301 • Email: admin@only-filter.com

Address: Rongding World, Xinhua District, Shijiazhuang City, Hebei Province

» Discover Factory Wholesale Cartridge Dust Collector Filter

References / Industry Authority & Forum Discussions

- Industrial Filtration Systems Forum: Real-world industrial filtration insights, filter selection strategies.

- Environmental-Expert.com Whitepapers: Technical advances in cartridge filter design.

- ResearchGate Publication – Filtration of Particles in Fiber Filters

- ScienceDirect Journal – Dust Collector Technologies

- FiltrationForum.com: Community technical reviews, use cases, troubleshooting reports.

- ScienceDirect – Dust Collector Overview: Comprehensive resource on dust collection engineering and trends.

-

Smart Filtration with Advanced Dust Cartridge TechnologyNewsJul.21,2025

-

Reliable Air Protection from Leading Gas Turbine Filter ManufacturersNewsJul.21,2025

-

Premium Air Filtration Solutions with Advanced Air Filter Cartridge TechnologyNewsJul.21,2025

-

Optimizing Industrial Air Quality with Dust Collector Filter CartridgeNewsJul.21,2025

-

Industrial Air Quality Enhancement with Advanced Filter CartridgeNewsJul.21,2025

-

High-Efficiency Protection with Advanced Gas Turbine FiltersNewsJul.21,2025

Email:

Email: