Tel:

+8618931101301

Tel:

+8618931101301

1月 . 06, 2025 18:58 Back to list

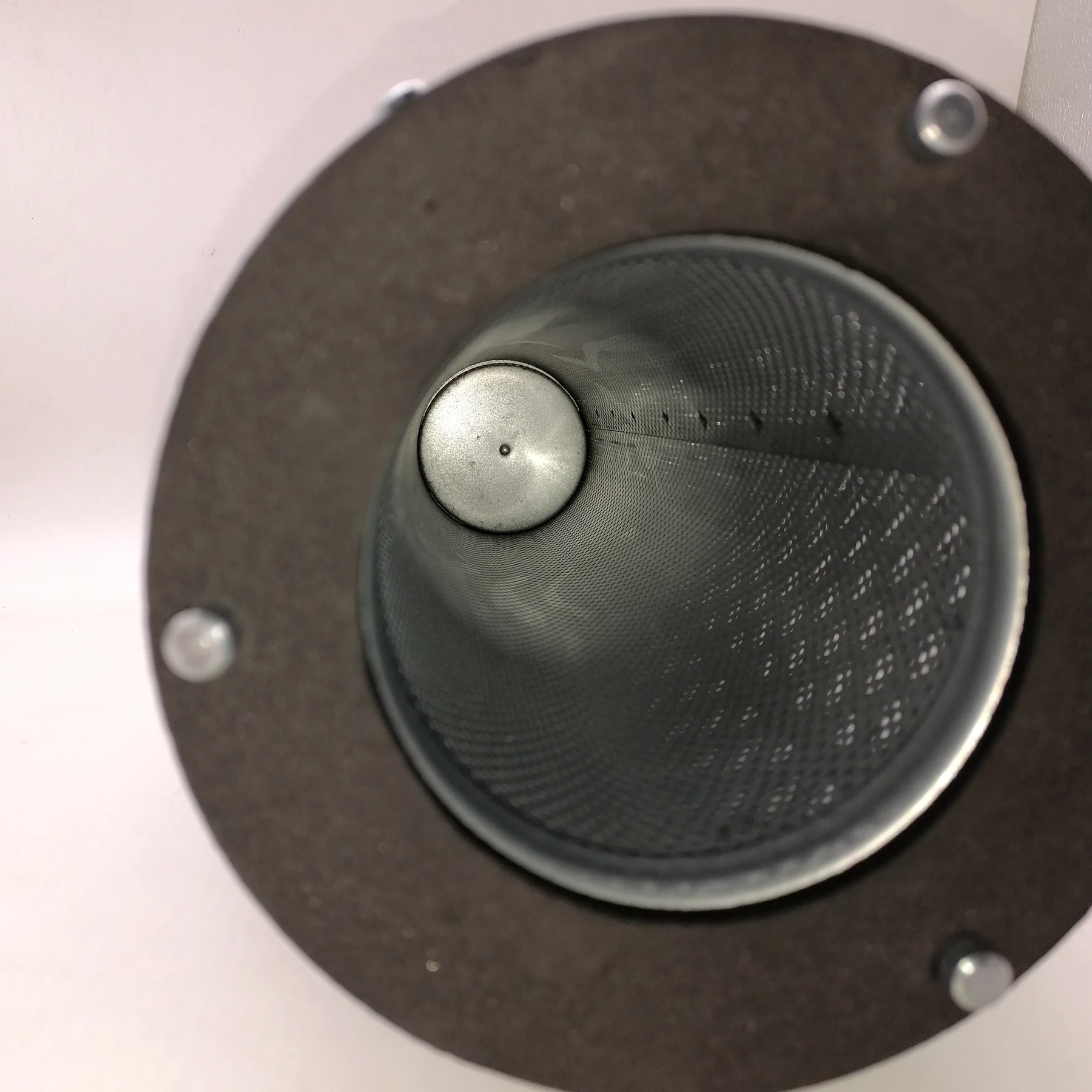

filter cartridge dust collector

Dust filter cartridges are essential components in maintaining clean air in industrial and commercial settings

. Designed to capture particulate matter and prevent contaminants from circulating in the environment, these cartridges are pivotal for ensuring a safe and efficient workplace. With years of experience in industrial filtration systems, it becomes evident that the selection and maintenance of dust filter cartridges directly impact an organization's operational efficiency and employee health.

A vital aspect of understanding how dust filter cartridges work is recognizing their construction and material. Typically, these cartridges consist of a pleated design, which maximizes the surface area for filtration. This design not only improves the filtration process but also extends the life of the cartridge, offering cost savings in the long run. The filter media, often made from cellulose, polyester, or a blend of synthetic materials, is chosen based on the specific application and type of dust particles involved. Each material offers distinct advantages in terms of durability, resistance to moisture, and filtration efficiency.

From a professional standpoint, choosing the right dust filter cartridge involves more than selecting a product from a catalog. It requires an expert evaluation of the working environment, including the type of dust particles, the volume of dust, and the operational temperatures. For instance, wood processing factories may encounter different challenges compared to metalworking shops, necessitating a bespoke filtration solution.

Our expertise reveals that proactive maintenance strategies significantly enhance the effectiveness and longevity of dust filter cartridges. This includes regular inspections for wear and tear, timely replacements based on differential pressure readings, and adhering to manufacturer guidelines for cleaning and maintenance. Proper handling prevents clogging and ensures that air quality standards are consistently met, safeguarding both machinery and personnel.

dust filter cartridge

Authoritativeness in the domain of dust filter cartridges is demonstrated through ongoing research and adaptation to changing industry regulations and environmental standards. Possessing certifications and compliance with organizations such as the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) is a testament to the quality and reliability of the products offered in the market. Staying updated with technological advancements, such as nanofiber coatings that enhance particle capture while maintaining airflow, also reflects a deep commitment to excellence.

Trustworthiness is built on providing clients with transparent information regarding the performance metrics of dust filter cartridges, comparisons between models, and customer testimonials that can offer insights into real-world applications. Case studies illustrating successful implementations and their impact on productivity and safety can further solidify a company's standing as a trusted partner in air filtration solutions.

In conclusion, dust filter cartridges are indispensable for maintaining a clean, efficient, and safe working environment. Their selection, use, and maintenance require a blend of practical experience and technical expertise. By focusing on quality, compliance, and customer satisfaction, organizations not only enhance their operational capabilities but also contribute positively to environmental sustainability and workplace health standards.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: