Tel:

+8615930870079

Tel:

+8615930870079

12月 . 15, 2024 13:11 Back to list

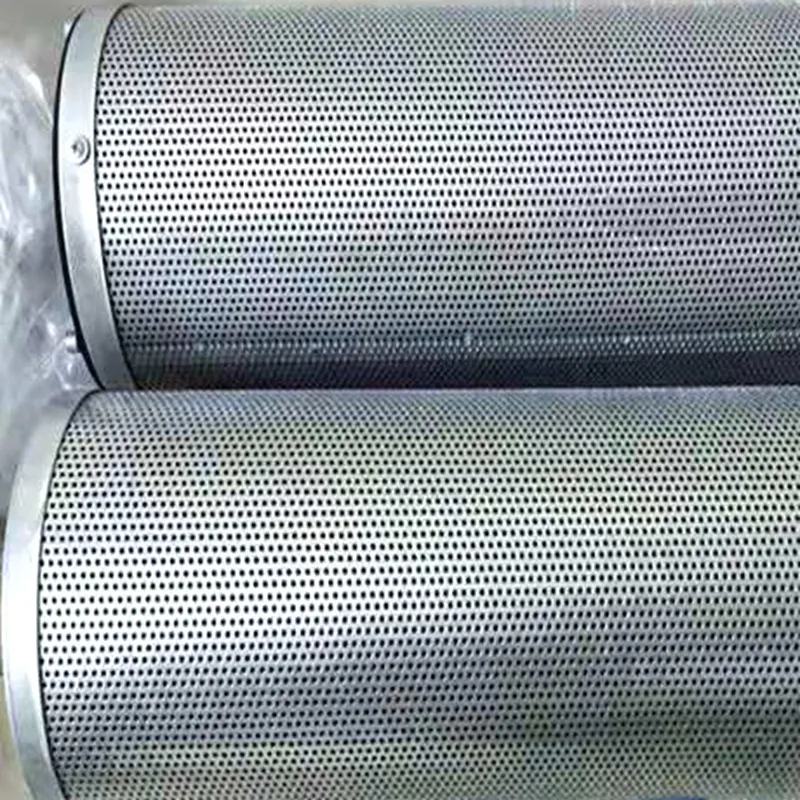

dust extractor pleated filter cartridges

The Importance of Pleated Filter Cartridges in Dust Extractors

In industries where dust and particulate matter are prevalent, maintaining a clean and safe working environment is crucial. Dust extractors play a vital role in controlling airborne contaminants, and at the heart of these systems are pleated filter cartridges. These filters not only enhance the efficiency of dust collection but also contribute to the overall effectiveness of the dust extraction process.

What are Pleated Filter Cartridges?

Pleated filter cartridges are specialized filter elements designed to capture dust and particulates from the air. Unlike traditional filters, pleated filters feature a series of folds or pleats that increase the surface area available for filtration. This design allows them to trap more dust and particles, leading to improved performance and longevity. The pleats also help in reducing the resistance to airflow, ensuring that the dust extraction system operates efficiently without overworking the machinery.

Benefits of Pleated Filters

One of the primary advantages of pleated filter cartridges is their high dust-holding capacity. This means that they can capture a larger volume of dust before needing replacement. As a result, businesses can reduce maintenance costs and minimize downtime associated with filter changes. Additionally, these filters are often made from high-quality materials that can withstand harsh conditions, ensuring durability and reliability.

dust extractor pleated filter cartridges

Another significant benefit is the enhanced filtration efficiency. Pleated filters are effective at capturing a wide range of particle sizes, including fine dust, allergens, and other airborne contaminants. This capability is particularly essential in industries such as woodworking, metalworking, pharmaceuticals, and food processing, where air quality standards must be upheld to ensure worker safety and product integrity.

Moreover, pleated filter cartridges are increasingly designed to be user-friendly. Many modern filters come with features such as easy installation and replacement, which helps reduce the labor involved in maintenance. Some manufacturers even offer filters with built-in indicators that signal when a filter is nearing the end of its operational life, thereby simplifying the upkeep process for facility managers.

Environmental Impact

Choosing pleated filter cartridges for dust extractors can also have positive environmental implications. Efficient filters reduce the amount of energy required to maintain airflow, leading to lower overall energy consumption. Additionally, by capturing more dust and particulate matter, these filters help protect the environment and comply with regulatory standards, thereby promoting a healthier workplace and broader community.

Conclusion

In summary, pleated filter cartridges are an integral component of effective dust extraction systems. Their increased surface area, high dust-holding capacity, and excellent filtration efficiency make them superior to conventional filters, providing a myriad of benefits for various industries. By investing in high-quality pleated filters, businesses can enhance their air quality, ensure the safety of their workforce, and maintain compliance with environmental regulations. As industries continue to prioritize cleanliness and efficiency, pleated filter cartridges will undoubtedly remain a fundamental element in the quest for cleaner air and healthier work environments.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: