Tel:

+8615930870079

Tel:

+8615930870079

11月 . 11, 2024 13:07 Back to list

dust cartridge

Understanding Dust % Cartridge Importance, Maintenance, and Applications

In the realm of industrial processes and various manufacturing sectors, effective dust management is critical for ensuring both worker safety and equipment longevity. One of the key components in dust management systems is the dust cartridge, which serves as a crucial filter for air purification in various industrial applications. This article will delve into the significance of dust cartridges, their maintenance requirements, and their applications across multiple industries.

The Importance of Dust Cartridges

Dust cartridges are designed to capture and separate solid particles such as dust, smoke, and aerosols from the air. Their efficiency directly influences air quality and overall operational safety. Industries that rely on heavy machinery, woodworking, metalworking, food processing, and pharmaceuticals produce substantial amounts of dust. Failure to manage this dust can lead to severe respiratory problems among workers and increase the risk of explosions in volatile environments.

The performance of a dust cartridge is often measured by its dust-holding capacity and filtration efficiency. Dust % cartridge refers to the percentage of dust captured by the filter, indicating how effective it is in maintaining clean air. A high dust % signifies greater efficiency and ensures a healthier working environment. Regular monitoring of their performance is essential; otherwise, reduced airflow and increased energy consumption can occur, leading to higher operational costs.

Maintenance of Dust Cartridges

To ensure optimal performance, dust cartridges require specific maintenance procedures. Regular inspection and testing of dust filtration systems are necessary to evaluate the dust % and overall filter performance. Here are some crucial maintenance tips to extend the life of a dust cartridge

1. Routine Cleaning Depending on the level of dust generated in the workspace, the cartridges should be cleaned regularly. You can use methods such as pulse jet cleaning, where bursts of air are used to dislodge dust from the filter.

2. Replacement Schedule Establish a schedule for cartridge replacement based on the manufacturer's recommendations and the specific conditions of the workplace. Monitoring the dust % can help in determining when a cartridge has reached its limit.

3. Seal Checks Regularly inspect seals and gaskets to ensure there are no air leaks. An efficient dust cartridge system depends on the integrity of seals. Air leaks can reduce efficiency, leading to higher levels of unfiltered particulates in the air.

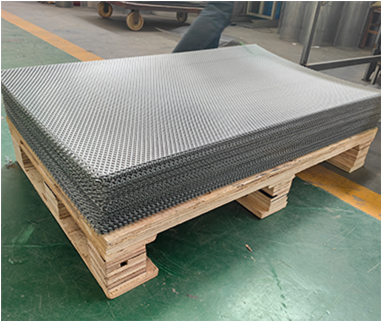

dust cartridge

4. Performance Monitoring Implementing pressure drop measurements across the filter can help in understanding the degree of clogging. Significant increases in pressure drop may indicate the need for cleaning or replacing the cartridge.

5. Training Staff Proper training of staff responsible for maintaining dust cartridges is essential. Understanding how to identify signs of wear and when to take action can mitigate risks and enhance safety.

Applications Across Industries

Dust % cartridges are utilized in various industries to mitigate dust and ensure compliance with safety regulations. Some of the most common applications include

- Woodworking In workshops where wood is cut, sanded, or finished, dust cartridges capture wood particles, preventing respiratory issues.

- Metal Fabrication Metalworking processes create hazardous dust and fumes. Dust cartridges are vital in capturing these particulates, protecting workers from harmful exposures.

- Food Processing Maintaining hygiene in food production is paramount. Dust cartridges help capture flour, sugar, and other food ingredients that can create airborne contaminants.

- Pharmaceutical Manufacturing In the pharmaceutical industry, it’s crucial to avoid contamination. Dust cartridges prevent the spread of active pharmaceutical ingredients (APIs) within production areas.

Conclusion

In conclusion, dust % cartridges play an essential role in ensuring safe and efficient operations across numerous industries. Their ability to capture harmful particulates significantly impacts air quality and worker safety. Proper maintenance and vigilance in monitoring dust cartridge performance can lead to cost savings and enhanced operational effectiveness. As industries evolve, the importance of effective dust management will only increase, making the dust cartridge an indispensable component in the pursuit of cleaner, safer work environments.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: