Tel:

+8615930870079

Tel:

+8615930870079

8月 . 28, 2024 22:05 Back to list

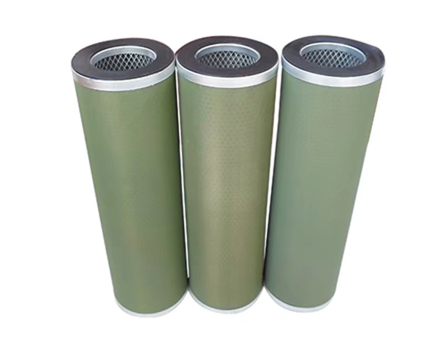

Cartridge Vacuum Filter - Efficient Filtration Solutions

Understanding Cartridge Vacuum Filters A Comprehensive Overview

Cartridge vacuum filters are essential components in various industrial processes, particularly in the realms of wastewater treatment, pharmaceuticals, food and beverage, and even in manufacturing sectors. These filters play a crucial role in separating particulates from liquids, thereby ensuring the clarity and quality of the final product. This article explores the mechanics, applications, and advantages of cartridge vacuum filters.

How Cartridge Vacuum Filters Work

At the core of a cartridge vacuum filter is a filtration system designed to operate efficiently under vacuum conditions. The filter consists of a cylindrical or tubular cartridge made of filtration media, such as polypropylene, nylon, or cellulose. When the contaminated liquid is introduced into the system, a vacuum is applied, causing the liquid to be drawn through the filter media. As the liquid passes through, solid particles are trapped on the surface or within the pores of the cartridge, while the clean filtrate is collected on the other side.

One of the significant advantages of using cartridge filters is their ability to achieve a high level of separation and clarity. The filtration media can be selected based on the specific application, allowing for versatility in filtering a wide range of particle sizes, from large solids to microscopic contaminants. Additionally, the filters are designed for easy replacement, which enhances operational efficiency and minimizes downtime.

Applications of Cartridge Vacuum Filters

The versatility of cartridge vacuum filters makes them applicable in various industries

. In water treatment facilities, they are utilized to remove contaminants from wastewater before it is released into the environment. This process not only meets regulatory standards but also contributes to environmental conservation.cartridge vacuum filter

In the pharmaceutical industry, cartridge vacuum filters are crucial in maintaining the sterility of products. They help in the clarification of solutions, removing bacteria and other impurities that could compromise drug safety and efficacy. Furthermore, in the food and beverage sector, these filters are employed to ensure the quality of beverages such as juices and wines, providing a clean and appealing product to consumers.

Beyond these applications, cartridge vacuum filters are also used in the manufacturing process, particularly when dealing with slurries or viscous liquids. They help in recovering valuable materials and reducing waste, leading to more sustainable production practices.

Advantages of Cartridge Vacuum Filters

The use of cartridge vacuum filters offers several benefits over traditional filtration methods. Firstly, they provide high filtration efficiency, which ensures that the processed liquid meets required standards for clarity and purity. Secondly, the compact design of cartridge filters allows for easier integration into existing systems without requiring significant modifications.

Additionally, these filters are economical in the long run. The cost-effective nature of the cartridges, combined with their ease of replacement, means reduced maintenance costs and less frequent downtime. Operators can quickly change out the cartridges, keeping processes running smoothly and efficiently.

Conclusion

Cartridge vacuum filters represent an excellent solution for various filtration needs across diverse industries. By effectively removing contaminants and ensuring product quality, they are crucial in modern industrial applications. As technology continues to advance, these filters will likely evolve further, providing even more efficient and sustainable solutions in the future. With their broad range of uses and numerous advantages, cartridge vacuum filters are indispensable in maintaining the integrity of products and protecting the environment.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: