Tel:

+8618931101301

Tel:

+8618931101301

nov . 09, 2024 09:23 Back to list

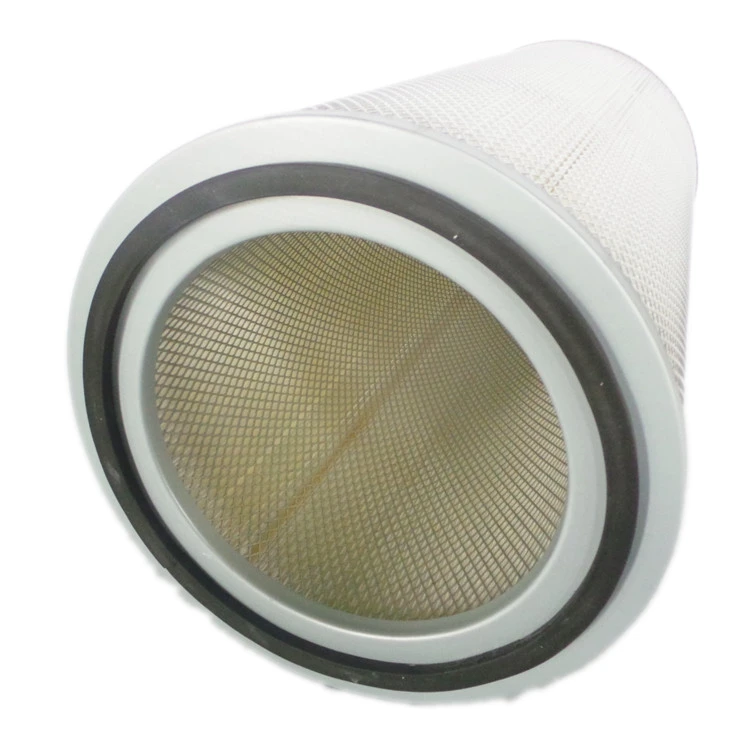

Stainless Steel Sintered Filter Cartridges for Enhanced Filtration Performance

Understanding SS Sintered Filter Cartridges Principles and Applications

In the rapidly advancing world of industrial filtration, stainless steel (SS) sintered filter cartridges have emerged as essential components known for their durability and efficiency. Constructed from metallic materials through a process known as sintering, these cartridges offer unique advantages such as thermal resistance, structural stability, and corrosion resistance. This article explores the principles behind SS sintered filter cartridges, their various applications, and factors to consider when selecting the appropriate filter for specific needs.

Principles of Sintered Filter Technology

Sintering is a process that involves the application of heat to compress and fuse powder materials without liquefaction. In the case of SS sintered filter cartridges, fine stainless steel powders are compacted and subjected to high temperatures, causing the particles to bond together while maintaining their porous structure. This results in a filter that exhibits a high degree of permeability and a controlled pore size distribution.

The porosity of sintered filters can be tailored during manufacturing, allowing for effective filtration of varying particulate sizes. The filters' pore sizes typically range from a few microns to larger openings, depending on the application requirements. Thus, SS sintered filter cartridges can efficiently capture contaminants and particulates while allowing the desired fluid or gas to pass through.

Advantages of SS Sintered Filter Cartridges

1. Durability One of the primary benefits of SS sintered filter cartridges is their robust nature. Unlike traditional polymer filters, stainless steel filters can withstand high temperatures and pressures, making them suitable for rigorous industrial applications.

2. Corrosion Resistance Stainless steel's innate resistance to corrosion makes it ideal for use in diverse chemical environments. It can handle aggressive chemicals and aggressive cleaning processes, thus ensuring a long operational lifespan.

3. Reusability SS sintered filters are easy to clean and can be reused multiple times. This not only reduces operational costs but also aligns with sustainability practices by minimizing waste.

ss sintered filter cartridge

4. Customizable The manufacturing process allows for customization in terms of pore size, length, and diameter. This versatility enables industries to obtain a filter that meets their specific filtration needs.

5. High Flow Rate Due to the open structure of sintered cartridges, the flow rates are typically higher compared to traditional filters, which is crucial in applications needing efficient fluid handling.

Applications of SS Sintered Filter Cartridges

The versatility of SS sintered filter cartridges makes them suitable for numerous applications across diverse industries

- Oil and Gas Used to remove particulate matter from drilling fluids, lubricants, and fuel, enhancing efficiency and equipment life. - Pharmaceuticals Ensures the purity of critical solvents and compounds, complying with stringent regulations. - Food and Beverage Employed in processes like beer filtration and wine clarification, where maintaining taste and quality is paramount. - Water Treatment Used for potable water filtration to remove suspended solids and pathogens, thus ensuring safe drinking water. - Chemical Processing Utilized to separate solids from various chemicals, preventing contamination and optimizing production processes.

Choosing the Right SS Sintered Filter Cartridge

When selecting the appropriate SS sintered filter cartridge, several factors should be taken into consideration

- Pore Size Determine the size of particles that need to be filtered based on the specific application. - Flow Rate Assess the required flow rates to ensure the chosen cartridge does not restrict operations. - Chemical Compatibility Ensure that the materials used in the cartridge are compatible with the fluids being filtered. - Maintenance Requirements Consider how often the filters will need cleaning and the ease of maintenance involved.

In conclusion, SS sintered filter cartridges are an invaluable asset in a range of industrial processes, offering durability, efficiency, and customization. Their ability to perform reliably under challenging conditions makes them a preferred choice for professionals looking to enhance filtration methods within their operations. As industries continue to evolve, the significance of such advanced filtration solutions will only continue to grow.

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

-

Air filter survival guide in high-dust environmentsNewsApr.23,2025

Email:

Email: