Tel:

+8615930870079

Tel:

+8615930870079

أغسطس . 10, 2025 04:00 Back to list

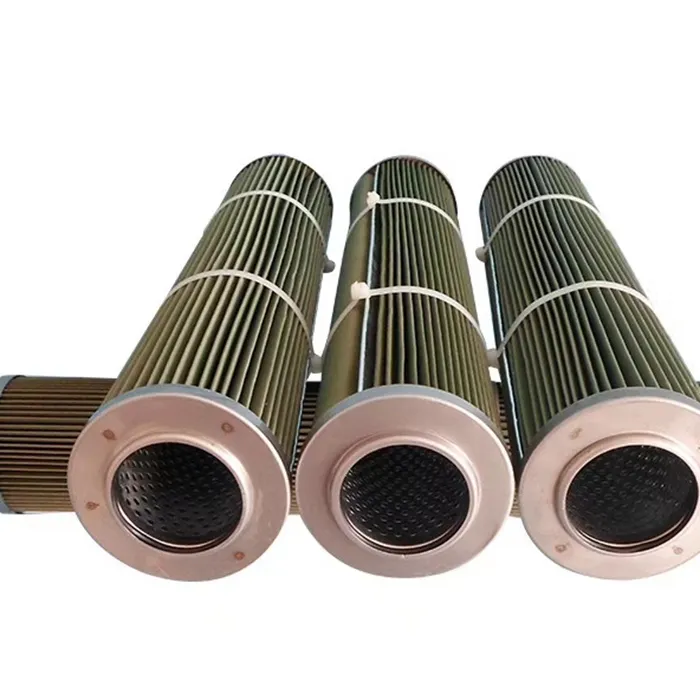

Wholesale Cartridge Dust Collector Filters - Factory Direct & Efficient

Understanding the Critical Role of Cartridge Dust Collector Filters in Modern Industry

In the contemporary industrial landscape, the management and mitigation of airborne particulate matter are not merely regulatory obligations but fundamental pillars of operational efficiency, worker safety, and environmental stewardship. Dust collection systems, and specifically their filtration components, stand at the forefront of these efforts, playing an indispensable role across a multitude of sectors. The strategic procurement of high-quality filtration solutions, particularly through channels like Factory Wholesale Cartridge Dust Collector Filter, offers a compelling value proposition for businesses seeking both peak performance and cost-effectiveness. These filters are engineered to capture a broad spectrum of dusts and fumes, ranging from fine particulates generated during grinding and welding to larger particles in woodworking or aggregates processing. Their design focuses on maximizing filter area within a compact footprint, leading to superior filtration efficiency and extended service intervals. The emphasis on wholesale channels ensures that industrial enterprises can access these crucial components at competitive price points, facilitating widespread adoption of advanced dust management practices. The evolution of filter media technology, coupled with advancements in manufacturing processes, has transformed cartridge filters into highly effective and versatile tools for industrial air purification. Enterprises are increasingly recognizing that investing in superior filtration not only ensures compliance with stringent environmental regulations, such as those set by EPA or OSHA, but also translates directly into tangible benefits like reduced equipment wear, improved product quality, and a healthier work environment, thereby enhancing overall productivity and profitability.

The prevailing industry trends underscore a pronounced shift towards more sustainable, efficient, and technologically integrated dust collection solutions. Businesses are actively seeking filters that offer higher capture efficiencies, lower pressure drops, and longer service lives to minimize energy consumption and reduce waste. This demand is driving innovation in filter media, including the development of nanofiber coatings, spunbond polyester, and specialized membrane materials that enhance filtration performance while resisting challenging operational conditions like high humidity or abrasive dusts. Furthermore, the integration of smart technologies, such as IoT-enabled sensors for real-time monitoring of filter performance and predictive maintenance, is gaining traction. These intelligent systems allow facility managers to optimize filter replacement schedules, prevent unexpected downtime, and respond proactively to changes in dust loading or environmental parameters. The global market for industrial dust collectors is projected to grow at a Compound Annual Growth Rate (CAGR) of approximately 5.8% from 2023 to 2030, reaching an estimated value of over USD 12 billion by 2030, according to industry reports. This growth is largely fueled by escalating environmental concerns, stricter regulatory frameworks worldwide, and the increasing recognition of the health implications associated with industrial dust exposure. Consequently, the demand for reliable and high-performance filtration components, like the Factory Wholesale Cartridge Dust Collector Filter, is expected to continue its upward trajectory, making strategic partnerships with reputable manufacturers and wholesale suppliers more critical than ever for maintaining operational excellence and achieving long-term sustainability goals.

The Advanced Manufacturing Process of Factory Wholesale Cartridge Dust Collector Filters

The production of a high-performance Factory Wholesale Cartridge Dust Collector Filter is a sophisticated process that integrates advanced materials science with precision engineering, ensuring each unit meets rigorous performance and durability standards. The core of any cartridge filter is its filter media, which is carefully selected based on the specific application requirements, including particle size, chemical composition of dust, temperature, and moisture content. Common filter media types include spunbond polyester, cellulose, blends of polyester and cellulose, nanofiber-coated media, PTFE membrane, and flame-retardant materials. The manufacturing journey typically begins with the preparation of the filter media, which is then precisely pleated to maximize the surface area for filtration within a compact cylindrical form factor. Pleating, often achieved using specialized machinery, ensures uniform spacing between pleats, which is critical for maintaining optimal airflow and dust loading capacity. The pleat count and depth are meticulously controlled to achieve the desired filtration efficiency and service life. Following the pleating stage, the pleated media is typically sealed at both ends using advanced techniques, such as hot melt adhesive bonding or polyurethane potting, to create a leak-proof seal that prevents unfiltered air from bypassing the media. This sealing process is paramount for the filter's overall efficiency and integrity.

The structural integrity of the Factory Wholesale Cartridge Dust Collector Filter is reinforced by robust end caps and an inner core. End caps, often made from galvanized steel, stainless steel, or polyurethane, are molded or stamped to precise dimensions and permanently attached to the pleated media assembly. The choice of end cap material and design varies depending on the operating environment and the specific dust collector model, ensuring a secure fit and resistance to corrosion or abrasion. An internal core, typically made from expanded metal mesh or perforated steel, provides essential support to the pleated media, preventing collapse under differential pressure during operation and reverse pulse cleaning. This core is engineered to allow for maximum airflow while maintaining structural stability. Throughout the entire manufacturing process, stringent quality control measures are implemented at every stage. This includes incoming material inspection, in-process checks of pleat spacing, adhesive bonding, and final product testing for pressure drop, filtration efficiency, and burst strength. Manufacturers adhere to international standards such as ISO 9001 for quality management systems, and filters may also meet specific industry standards like ANSI/ASHRAE for air filtration products or various fire retardancy standards where applicable. The use of advanced manufacturing technologies, including automated pleating lines and robotic assembly, minimizes human error and ensures consistency in product quality across large production runs, which is particularly beneficial for wholesale procurement. The resulting filters are designed for an optimal service life, often ranging from 6,000 to 12,000 operational hours or more, depending on the specific application, dust loading, and maintenance practices. This extended lifespan contributes significantly to lower total cost of ownership for industrial clients.

Key Technical Parameters and Performance Metrics of Cartridge Dust Filters

Selecting the appropriate Factory Wholesale Cartridge Dust Collector Filter requires a thorough understanding of its key technical parameters and performance metrics. These specifications dictate a filter's suitability for a given application, its efficiency, energy consumption, and overall operational longevity. One of the primary parameters is the Filter Area, measured in square feet or square meters, which represents the total surface area of the filter media available for dust collection. A larger filter area generally allows for higher airflow rates with lower pressure drop, or a longer service life before requiring cleaning or replacement. However, it must be balanced against the physical constraints of the dust collector housing. Another critical metric is Filtration Efficiency, often expressed as a percentage of particles captured at a specific size range. For instance, an industrial filter might boast 99.9% efficiency at 0.5 microns, meaning it captures nearly all particles larger than half a micron. Efficiency ratings can be categorized by standards like MERV (Minimum Efficiency Reporting Value) for general filtration, or HEPA (High-Efficiency Particulate Air) for critical applications requiring capture of 99.97% of particles at 0.3 microns. The Pressure Drop (or differential pressure) across the filter is a measure of the resistance to airflow. Initially, a new filter has a low pressure drop, but as dust accumulates on its surface, resistance increases. A higher pressure drop translates to increased energy consumption by the fan and reduced airflow, eventually necessitating cleaning or replacement. Monitoring this parameter is crucial for optimizing system performance and energy costs.

Further technical considerations for a Factory Wholesale Cartridge Dust Collector Filter include its Temperature Rating, indicating the maximum continuous operating temperature the filter media and components can withstand without degradation. This is vital for high-temperature industrial processes like metal casting or certain chemical reactions. Similarly, the Moisture and Chemical Resistance of the filter media is essential for applications involving humid air or corrosive gases, where specialized coatings (e.g., PTFE membrane) or media types are employed to prevent premature failure. The Air-to-Cloth Ratio, defined as the volume of air flowing through the filter per minute divided by the total filter area, is a crucial design parameter that influences filter sizing and performance. A lower air-to-cloth ratio generally indicates less stress on the filter media, leading to longer life and lower pressure drop, but may require more filters. The filter's mechanical design also includes specifications for its dimensions (diameter, length), mounting method (open/closed end, specific flange types), and the material of construction for end caps and inner core, which must be compatible with the environment (e.g., galvanized steel for general use, stainless steel for corrosive environments, or food-grade materials). Understanding these parameters allows B2B buyers and engineers to specify filters that not only meet regulatory compliance but also deliver optimal performance, extend maintenance cycles, and contribute to significant operational savings over the lifespan of the dust collection system. For example, a filter with superior efficiency at lower pressure drop might have a slightly higher initial cost but will yield substantial energy savings over time, showcasing the long-term value proposition of high-quality cartridge filters.

Typical Parameters for Factory Wholesale Cartridge Dust Collector Filters

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Filter Media Type | Spunbond Polyester, Cellulose, Blends, PTFE Membrane, Nanofiber | Determines efficiency, chemical resistance, abrasion resistance, and cost. |

| Filter Area | 150 - 350 sq ft (14 - 32 sq m) per cartridge | Higher area allows higher flow, lower pressure drop, or longer life. |

| Filtration Efficiency | 99.9% at 0.5 micron (MERV 10-16 typical, HEPA for critical) | Percentage of particles captured at a specified size; crucial for air quality. |

| Initial Pressure Drop | 0.5 - 1.5 inches w.g. (125-375 Pa) for new filter | Resistance to airflow; impacts fan energy consumption. |

| Max Operating Temperature | 180°F - 275°F (82°C - 135°C) for standard media; up to 400°F (204°C) for specialty | Determines suitability for high-temperature applications. |

| Air-to-Cloth Ratio | 1.5:1 to 3.0:1 (CFM/sq ft or m³/min/m²) for general industrial | Design parameter influencing filter sizing, life, and pressure drop. |

| Diameter Range | 8" to 16" (200mm to 400mm) common | Must match existing dust collector housing specifications. |

| Length Range | 24" to 60" (610mm to 1524mm) common | Must match existing dust collector housing specifications. |

| End Cap Material | Galvanized Steel, Stainless Steel, Polyurethane, Aluminum | Ensures secure fit and resistance to corrosion, temperature. |

Diverse Application Scenarios and Industry Benefits of Cartridge Filters

The versatility and high performance of the Factory Wholesale Cartridge Dust Collector Filter make it an indispensable component across an expansive array of industrial sectors. Its compact design and efficient filtration capabilities allow it to address varied particulate challenges, from fine powders to abrasive chips, ensuring compliance, safety, and operational continuity. In the Cement and Mineral Processing industries, these filters are critical for managing vast quantities of fine dust generated during crushing, grinding, kiln operations, and material handling. They prevent particulate emissions into the atmosphere, recover valuable product, and protect downstream equipment from abrasive wear, significantly extending the lifespan of machinery and reducing maintenance costs. For instance, in a cement plant, the effective capture of cement dust, often sub-micron in size, not only ensures compliance with PM2.5 emission limits but also allows for the reclamation of valuable material, translating to substantial economic gains. The Pharmaceutical and Food Processing sectors demand exceptionally high levels of air purity to prevent cross-contamination, ensure product integrity, and comply with strict health and safety regulations (e.g., FDA, GMP standards). Cartridge filters with specialized media, such as those with PTFE membranes, are widely used in these environments for collecting fine pharmaceutical powders or food ingredients, often in cleanroom conditions, where filter integrity and ease of validation are paramount. Their ability to capture even sub-micron contaminants effectively prevents product spoilage and safeguards consumer health.

In the Metalworking and Fabrication industries, which encompass welding, grinding, plasma cutting, and laser cutting, the generation of metal fumes and fine dust is a significant concern. Factory Wholesale Cartridge Dust Collector Filter solutions with flame-retardant or conductive media are frequently deployed to manage these hazardous airborne contaminants, protecting workers from respiratory illnesses and mitigating the risk of combustible dust explosions. For example, in a large-scale automotive manufacturing plant, cartridge filters are integrated into centralized dust collection systems that serve multiple robotic welding stations, effectively capturing metallic fumes and particulate matter, thus maintaining superior indoor air quality and ensuring worker comfort and safety. The Woodworking and Furniture Manufacturing industry benefits from these filters by effectively collecting sawdust and wood chips, which are highly combustible and can pose significant fire hazards. Efficient dust collection not only improves visibility and cleanliness but also reduces fire risks and can even allow for the reuse of wood waste for energy generation or other purposes. Furthermore, in the Chemical and Plastics Manufacturing sectors, specialized cartridge filters are used for handling corrosive, sticky, or hygroscopic dusts, often requiring unique filter media treatments or configurations to prevent blinding and maintain filtration efficiency over extended periods. The advantages across these diverse applications are multi-faceted: including significant energy savings due to lower system pressure drops and reduced fan power consumption, enhanced corrosion protection for equipment and structures, improved worker health and safety by maintaining clean breathable air, compliance with ever-tightening environmental regulations, and extended equipment lifespan by protecting machinery from abrasive dusts, ultimately leading to a lower total cost of ownership and a more sustainable industrial operation.

Strategic Manufacturer Comparison and Tailored Customization Solutions

When sourcing a Factory Wholesale Cartridge Dust Collector Filter, discerning industrial buyers and procurement professionals understand that not all manufacturers are created equal. A strategic comparison goes beyond just price, delving into critical aspects such as manufacturing quality, technical expertise, customization capabilities, and after-sales support. Reputable manufacturers distinguish themselves through rigorous quality control processes, adherence to international standards like ISO 9001:2015, and the use of premium-grade raw materials. They invest in advanced production lines that ensure consistent pleat spacing, robust end cap sealing, and durable filter media. For instance, a manufacturer with a proven track record might demonstrate their quality through third-party certifications (e.g., test reports from accredited laboratories confirming filtration efficiency and pressure drop performance) or by showcasing long-standing relationships with major industrial clients. The breadth of their product portfolio, including a variety of filter media (e.g., spunbond polyester, cellulose, PTFE membrane, nanofiber, conductive media, anti-static treatments), sizes, and end cap configurations, indicates a robust capability to meet diverse industrial needs. Furthermore, the capacity for research and development, allowing for the introduction of innovative filter technologies like enhanced surface filtration media or energy-saving designs, signifies a forward-thinking partner.

Our company prides itself on offering unparalleled customization solutions for the Factory Wholesale Cartridge Dust Collector Filter, a critical differentiator in a market saturated with generic options. We recognize that every industrial application presents unique challenges, whether it's dealing with highly abrasive dust, extreme temperatures, corrosive gases, or specific particulate sizes requiring ultra-high efficiency. Our technical team works collaboratively with clients, conducting detailed assessments of their operational environment, dust characteristics, existing dust collector specifications, and performance objectives. This allows us to recommend and engineer filters that are precisely tailored to their needs. Customization options extend to:

- Media Selection: From standard spunbond polyester for general dust to specialized PTFE membrane for sticky or hygroscopic dusts, or nanofiber media for superior sub-micron particle capture and improved pulse cleaning. We also offer flame-retardant and anti-static treatments for combustible dust environments.

- Dimensions and Configurations: Manufacturing filters with specific diameters, lengths, and mounting styles (e.g., open/open, closed/open with bolt holes, various gasket options) to perfectly match existing dust collector systems, regardless of OEM.

- End Cap Materials: Offering galvanized steel, stainless steel (304 or 316 for corrosive applications), aluminum, or durable polyurethane, chosen based on environmental compatibility and required sealing properties.

- Inner Core Design: Customizing the internal support core for specific flow rates or pulse-jet cleaning intensity, ensuring longevity without impeding airflow.

- Surface Treatments: Applying hydrophobic, oleophobic, or other specialized coatings to enhance dust release and prolong filter life in challenging conditions.

Real-World Application Cases and Performance Validation

The tangible benefits of investing in a high-quality Factory Wholesale Cartridge Dust Collector Filter are best illustrated through real-world application cases, where their superior performance directly translates into operational advantages and significant return on investment. These filters are not just components; they are solutions to complex industrial challenges, ranging from environmental compliance to optimizing production efficiency. Consider a major steel fabrication plant that was facing persistent issues with visible emissions from their welding fume extraction system. Their existing filters were rapidly blinding, leading to frequent manual cleaning, high differential pressure, and non-compliance with local air quality regulations. After consulting with our experts, they transitioned to our nanofiber-coated cartridge filters, specifically engineered for welding fume capture. The result was remarkable: filtration efficiency for sub-micron particles (PM2.5) improved from 98.5% to 99.9% consistently, reducing visible emissions to near-zero levels. The average operational lifespan of the filters increased from 6 months to 18 months, leading to a 67% reduction in filter replacement costs. Furthermore, the lower stable pressure drop achieved with the new filters resulted in a 15% reduction in fan energy consumption, contributing to significant electricity bill savings and a smaller carbon footprint. This case exemplifies how advanced filter technology can simultaneously address environmental, economic, and operational objectives.

Another compelling example comes from a large-scale pharmaceutical manufacturer dealing with highly sensitive and fine pharmaceutical powders, where preventing cross-contamination and ensuring product purity are paramount. Their existing dust collection system, while functional, relied on bag filters that proved challenging to clean, prone to media migration, and difficult to validate for FDA compliance. We provided a custom Factory Wholesale Cartridge Dust Collector Filter solution featuring PTFE membrane media with electrostatically dissipative properties, installed in their pulse-jet collectors. The PTFE membrane offered superior surface filtration, preventing particle penetration into the media, which drastically improved cleaning cycles and eliminated cross-contamination risks. Performance validation tests, conducted both in-house and by independent third-party laboratories, confirmed 99.995% filtration efficiency at 0.2 microns, exceeding the client's stringent requirements. The client also reported a 40% reduction in compressed air consumption for pulse cleaning due to the superior dust release properties of the PTFE media, leading to substantial energy savings. The seamless integration of these specialized filters into their existing system, coupled with comprehensive technical support during installation and commissioning, underscored the value of a trusted wholesale partner. These application examples, backed by quantitative data, highlight that choosing the right cartridge filter is a strategic decision that drives efficiency, ensures compliance, enhances safety, and ultimately contributes to the long-term profitability and sustainability of industrial operations, solidifying the reputation of our filters as reliable, high-performance solutions.

Ensuring Trustworthiness: Quality Assurance, Certifications, and Customer Support

In the B2B landscape, particularly when it comes to critical components like the Factory Wholesale Cartridge Dust Collector Filter, trustworthiness is paramount. It is built upon a foundation of verifiable quality assurance, industry-recognized certifications, and unwavering customer support. Our commitment to quality begins with strict raw material procurement, ensuring that all filter media, end cap materials, and adhesives meet or exceed industry specifications. We maintain a comprehensive Quality Management System (QMS) certified to ISO 9001:2015 standards, which governs every stage of our manufacturing process, from initial design and material sourcing to production, testing, packaging, and delivery. This certification is not merely a formality; it represents a systemic approach to ensuring consistent product quality, continuous improvement, and customer satisfaction. Each batch of filter media undergoes rigorous testing for parameters such as air permeability, burst strength, and filtration efficiency before it is incorporated into a final product. Finished cartridge filters are subjected to a series of performance validation tests, including initial pressure drop, overall filtration efficiency, and burst pressure testing to simulate operational stresses. Our internal testing protocols often exceed industry benchmarks, and we regularly collaborate with independent, accredited laboratories for third-party verification of our filter performance data, offering an unbiased validation of our claims. This commitment to transparent and verifiable quality data builds immense confidence with our wholesale clients, providing them with the assurance that they are investing in reliable and high-performing filtration solutions.

Beyond robust manufacturing and testing, our approach to trustworthiness extends through our comprehensive service offerings. We understand that timely delivery is crucial for industrial operations to minimize downtime and maintain production schedules. Our well-established logistics network and efficient production planning enable us to offer competitive delivery cycles, often ranging from 2-4 weeks for standard wholesale orders, with expedited options available for urgent requirements. Each shipment of Factory Wholesale Cartridge Dust Collector Filter products is meticulously packaged to prevent damage during transit, ensuring that they arrive in perfect condition, ready for immediate installation. Furthermore, we stand behind the quality and performance of our products with a robust warranty commitment, typically offering a 12-month warranty against manufacturing defects and material failures under normal operating conditions. This warranty provides our clients with peace of mind and reflects our confidence in the durability and reliability of our filters. Our dedicated customer support team and technical service engineers are available to provide expert guidance on filter selection, installation best practices, and troubleshooting common issues. We offer post-sales support that includes performance monitoring advice, media lifespan analysis, and recommendations for optimizing dust collector system performance. This holistic approach, combining world-class manufacturing with transparent quality assurance and responsive customer service, positions us as a truly trustworthy partner for all industrial filtration needs, helping our clients achieve superior air quality, operational efficiency, and regulatory compliance.

Frequently Asked Questions (FAQ)

-

Q: How do I determine the correct Factory Wholesale Cartridge Dust Collector Filter for my application?

A: Selecting the right filter involves understanding your dust characteristics (particle size, abrasiveness, moisture content, explosivity), operating temperature, airflow volume (CFM/m³/hr), and existing dust collector model. Our technical sales team can guide you through this process, often requesting a sample of your dust or detailed specifications of your current system to ensure a precise match and optimal performance.

-

Q: What is the typical lifespan of a cartridge dust collector filter?

A: The lifespan varies significantly based on dust loading, dust type, operating hours, pulse-jet cleaning frequency and effectiveness, and environmental conditions. Generally, a high-quality Factory Wholesale Cartridge Dust Collector Filter can last anywhere from 6,000 to 12,000 operational hours or more. Factors like high humidity, sticky dusts, or abrasive particles can reduce life, while effective cleaning systems and appropriate media selection can extend it. Regular monitoring of differential pressure is key to determining optimal replacement times.

-

Q: Can your filters be customized for unique applications or obsolete collector models?

A: Absolutely. Customization is a core strength. We can manufacture Factory Wholesale Cartridge Dust Collector Filter units with specific dimensions, end cap configurations, gasket materials, and specialized filter media to perfectly fit virtually any dust collector system, including those for which OEM filters are no longer available. Provide us with your specifications or a sample, and we can engineer a precise replacement or upgrade.

-

Q: What environmental certifications or standards do your products meet?

A: Our filters are designed to help clients achieve compliance with various local and international air quality standards, such as EPA regulations, OSHA permissible exposure limits (PELs), and industry-specific guidelines. While the filters themselves may not carry direct "environmental certifications" in the sense of a product label, their performance characteristics (e.g., high filtration efficiency for PM2.5/PM10) enable dust collection systems to meet these stringent emission requirements. Our manufacturing processes are also ISO 9001 certified, demonstrating our commitment to quality that supports environmental performance.

-

Q: What is your typical delivery lead time for wholesale orders?

A: For standard Factory Wholesale Cartridge Dust Collector Filter orders, our typical lead time ranges from 2 to 4 weeks, depending on order volume and specific filter configurations. We also offer expedited production and shipping options for urgent requirements. Please contact our sales team with your specific needs for an accurate quote and delivery schedule.

The Future of Industrial Dust Collection and Our Role

The landscape of industrial dust collection is continually evolving, driven by advancements in material science, increasingly stringent environmental regulations, and the integration of smart technologies. The future promises dust collection systems that are not only more efficient but also more intelligent, requiring filtration components like the Factory Wholesale Cartridge Dust Collector Filter to evolve in parallel. Key trends shaping this future include the wider adoption of IoT (Internet of Things) and AI for predictive maintenance and real-time performance monitoring. Sensors integrated within dust collectors will monitor filter pressure drop, airflow, and dust loading, transmitting data to cloud-based analytics platforms. This will enable facility managers to anticipate filter replacement needs, optimize pulse-jet cleaning cycles, and diagnose potential issues before they lead to costly downtime. The development of self-cleaning or self-healing filter media, while still in nascent stages, represents a long-term aspiration to further extend filter life and reduce manual intervention. Furthermore, there is a growing emphasis on energy recovery from exhaust air, especially in high-temperature applications, and the design of filtration systems that can efficiently separate and recover valuable fine powders for reuse or recycling, aligning with circular economy principles.

Our company is actively engaged in these transformative trends, continuously investing in research and development to ensure our Factory Wholesale Cartridge Dust Collector Filter offerings remain at the forefront of innovation. We are exploring next-generation filter media with enhanced surface properties for even lower pressure drop and superior dust release, potentially reducing compressed air consumption for cleaning by an additional 20-30%. Our focus also extends to developing filter solutions optimized for specific emerging industrial processes and materials, such as those in additive manufacturing (3D printing) where ultra-fine metallic powders are prevalent, or in new composite material production. By partnering with leading research institutions and material scientists, we aim to introduce filters that not only meet but anticipate future industrial demands for efficiency, safety, and environmental compliance. Our commitment to providing high-quality, customizable, and technologically advanced cartridge filters ensures that our wholesale clients are equipped with the best possible tools to navigate the complexities of industrial dust management, securing a cleaner, safer, and more productive operational environment for years to come. The enduring value proposition of our filters lies in their ability to deliver consistent performance, longevity, and significant operational savings, making them a strategic investment for any industrial enterprise.

Industry References and Further Reading

- Air & Waste Management Association (AWMA): Provides technical papers and discussions on industrial air pollution control technologies, including advancements in fabric filtration and cartridge filter design. https://www.awma.org/technical-papers

- Filtration Society: An international body promoting scientific knowledge and research in filtration and separation, with numerous publications on filter media performance and dust collection. https://www.filtrationsociety.com/

- Journal of Environmental Chemical Engineering: Often features peer-reviewed articles on industrial air pollution control, including filter design and efficiency studies. https://www.sciencedirect.com/journal/journal-of-environmental-chemical-engineering

- Occupational Safety and Health Administration (OSHA): Provides detailed guidelines and regulations on permissible exposure limits for various industrial dusts and the importance of effective dust collection. https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1000

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: