Tel:

+8615930870079

Tel:

+8615930870079

ديسمبر . 11, 2024 10:07 Back to list

Optimizing Air Intake Filters for Enhanced Turbine Performance and Longevity

Turbine Air Intake Filters Essential Components for Optimal Engine Performance

In the modern era of engineering, particularly in aviation and power generation, the reliability and efficiency of turbine engines are of paramount importance. One of the critical components that significantly influence the performance and longevity of these engines is the air intake filter. Turbine air intake filters play a crucial role in ensuring that clean, unobstructed air enters the engine, thereby safeguarding it from potential contaminants and maintaining optimal operation.

Understanding the Importance of Air Intake Filters

Turbine engines, whether jet engines in aircraft or gas turbines in power plants, rely on a continuous flow of air for combustion. The air intake system is designed to harness and channel this airflow into the engine's combustion chamber. However, the atmosphere around us is filled with various contaminants, including dust, dirt, pollen, and other particles that can harm engine components. This is where air intake filters come into play.

Air intake filters act as a protective barrier, capturing these airborne contaminants before they can enter the engine. Without adequate filtration, these particles can lead to wear and tear on engine components, reduced efficiency, and ultimately, costly repairs. Therefore, maintaining clean air intake filters is critical for optimizing engine performance and extending the lifespan of the engine.

Types of Turbine Air Intake Filters

Turbine air intake filters come in various types, each designed to meet specific operational needs and environmental conditions. The most common types include

1. Panel Filters These are typically made of synthetic fibers or foam and are designed to be easily replaceable. They are suited for stationary applications like gas turbines in power plants.

2. Cylindrical Filters Often used in aircraft engines, these filters are circular and can fit various intake configurations. They are also designed to provide high airflow while maintaining effective filtration.

3. V-Bank Filters This design features multiple filter elements arranged in a V-shape, allowing for a more compact installation while maximizing surface area for contamination capture.

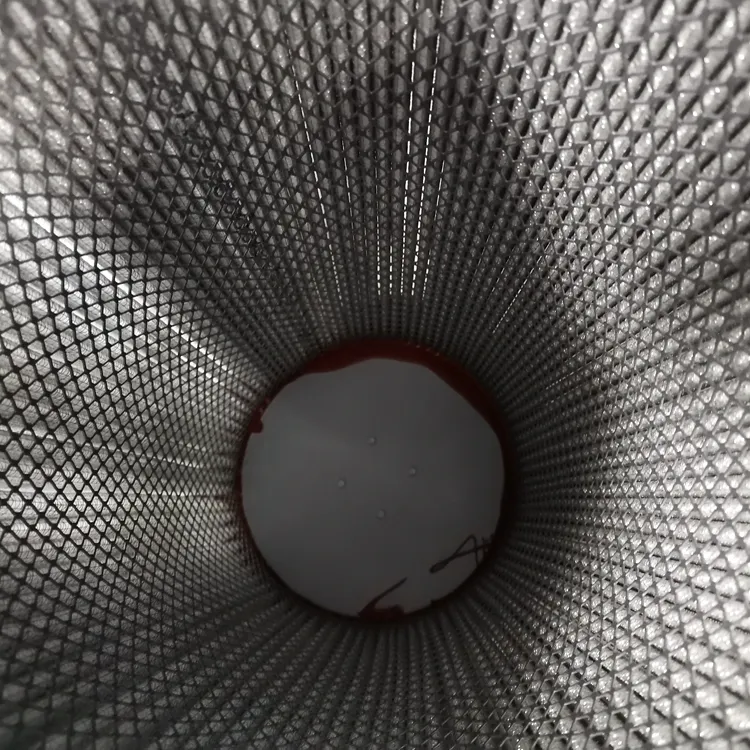

turbine air intake filters

4. HEPA Filters High-Efficiency Particulate Air filters are capable of trapping extremely small particles, making them ideal for critical applications where cleanliness counts, such as in aviation.

Optimizing Turbine Air Intake Filters

To ensure optimal performance, turbine air intake filters must be regularly inspected and maintained. Contaminated filters can restrict airflow, leading to engine inefficiencies and potential overheating. Engine operators should establish a routine maintenance schedule based on the manufacturer's recommendations and the operating environment.

Another critical factor in maintaining effective filtration is to choose the right filter for the specific application. The operational environment, including the levels of dust and other particulates, should dictate the type of filter selected. Moreover, advances in filtration technology have led to the development of filters designed to handle extreme conditions, balancing the need for airflow with superior filtration capabilities.

The Future of Turbine Air Intake Filtration

As the aviation and energy industries continue to evolve, so too will the technology behind turbine air intake filters. With the increasing focus on environmental sustainability, future innovations may include eco-friendly filter materials that can be reused or recycled. Additionally, the integration of smart technologies and IoT (Internet of Things) capabilities may allow for real-time monitoring of filter performance, enabling predictive maintenance that can avert potential failures before they occur.

Furthermore, the growing trend towards hybrid and electric propulsion systems could change the requirements and design of air intake systems, pushing manufacturers to rethink filter designs to accommodate these new technologies.

Conclusion

In conclusion, turbine air intake filters are a fundamental aspect of turbine engine operation, playing a critical role in protecting engine integrity and ensuring efficient performance. As the industry continues to advance, these filters will evolve in design and technology, further enhancing their effectiveness. Operators must remain vigilant in filter maintenance and selection to maximize engine performance and lifecycle. Investing in high-quality air intake filtration not only extends the life of turbine engines but also contributes to overall operational efficiency, making it an essential component of modern engineering practices.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: