Tel:

+8615930870079

Tel:

+8615930870079

ديسمبر . 11, 2024 06:24 Back to list

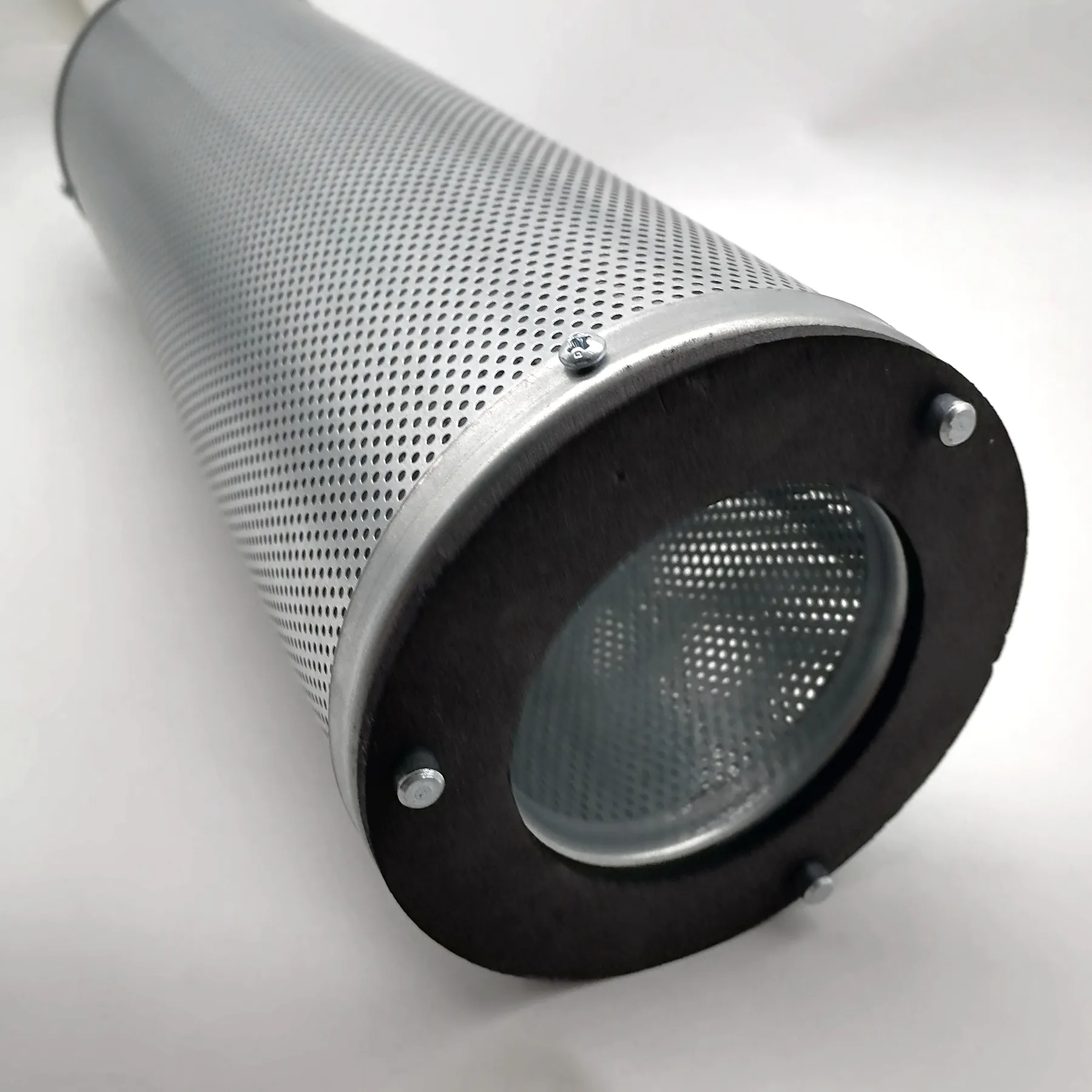

Metal Filter Element Specifications and Applications for Optimal Performance

Understanding Metal Filter Elements A Key Component in Filtration Systems

In the fluid processing industry, filtration plays a critical role in ensuring that liquids and gases remain uncontaminated and meet quality standards. Metal filter elements have emerged as a reliable solution for various filtration challenges. This article provides an overview of metal filter elements, exploring their construction, benefits, applications, and maintenance considerations.

What Are Metal Filter Elements?

Metal filter elements are filtration devices made from various metals such as stainless steel, aluminum, or other alloys. They are designed to capture particulates from liquids and gases, providing superior performance in demanding environments. Due to their robust construction, metal filter elements are capable of withstanding high temperatures and pressures, making them ideal for industrial applications.

Construction and Design

The design of metal filter elements varies widely, but they commonly consist of a mesh or porous structure that allows for effective filtration while maintaining high flow rates. These elements can be manufactured in various forms—replacement cartridges, discs, or housings—depending on the application requirements. They can also feature different pore sizes, allowing them to filter out specific particulate sizes.

Stainless steel is a popular choice due to its corrosion resistance and longevity, while other materials may be used for specialized applications. The surface treatment of metal filter elements, such as passivation or coating, can enhance their performance by further increasing resistance to corrosion and fouling.

Benefits of Metal Filter Elements

1. Durability Metal filter elements are known for their robustness. They can withstand harsh chemical environments and extreme temperatures, offering a longer service life than their non-metal counterparts.

2. Reusability Many metal filter elements are designed to be cleaned and reused. This not only reduces costs but also minimizes waste, making them an environmentally friendly option.

metal filter element

3. High Flow Capacity Because of their porous structure and varying mesh sizes, metal filter elements can facilitate high flow rates without compromising the filtration quality, making them suitable for high-volume applications.

4. Chemical Compatibility With proper selection, metal filters can be used in various chemical environments, making them versatile for different industries, including food and beverage, pharmaceuticals, and petrochemicals.

5. Effective Filtration Metal filter elements can effectively capture a wide range of particle sizes, including fine particulate matter, ensuring the purity of the processed material.

Applications

Metal filter elements find applications across several industries

- Food and Beverage Used to ensure product purity and extend equipment life by filtering out contaminants. - Pharmaceuticals Critical in maintaining the integrity of pharmaceutical products by removing unwanted particulates. - Chemicals Widely used in the chemical processing industry to protect equipment and enhance product quality. - Oil and Gas Employed to filter out solids and particulates from drilling fluids and other processes.

Maintenance Considerations

To ensure optimal performance, regular maintenance of metal filter elements is essential. Cleaning methods may include backwashing, ultrasonic cleaning, or chemical cleaning, depending on the degree of fouling and the type of contaminants. Inspecting the filter elements for signs of wear or damage can prevent unexpected failures and ensure a long service life.

Conclusion

In summary, metal filter elements are a vital component in many industrial filtration systems due to their durability, reusability, and effective filtration capabilities. With a wide range of applications and benefits, they are increasingly becoming the preferred choice in various industries. Understanding their construction, benefits, and maintenance requirements allows companies to make informed decisions and maintain the efficiency and effectiveness of their filtration systems.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: