Tel:

+8618931101301

Tel:

+8618931101301

نوفمبر . 06, 2024 01:29 Back to list

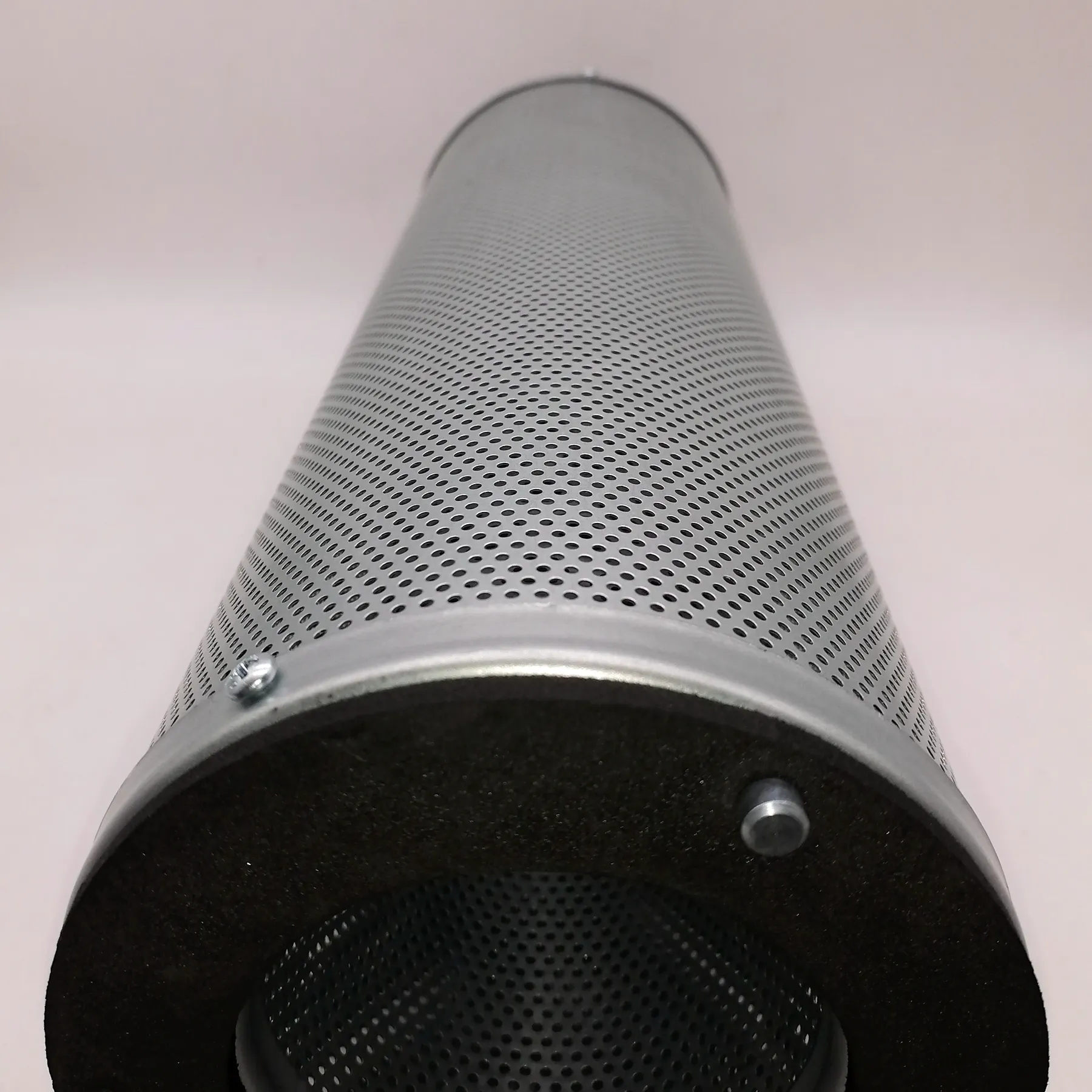

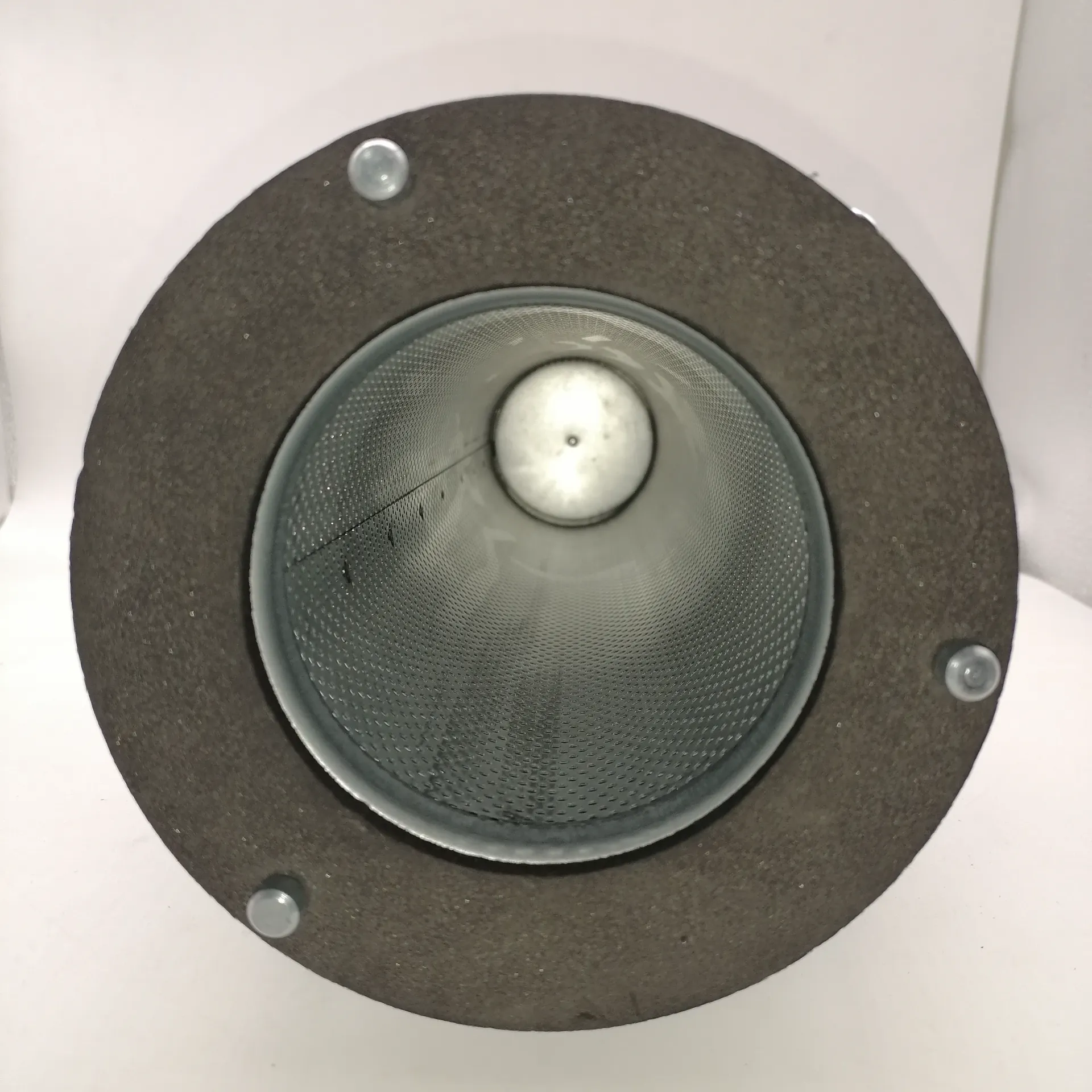

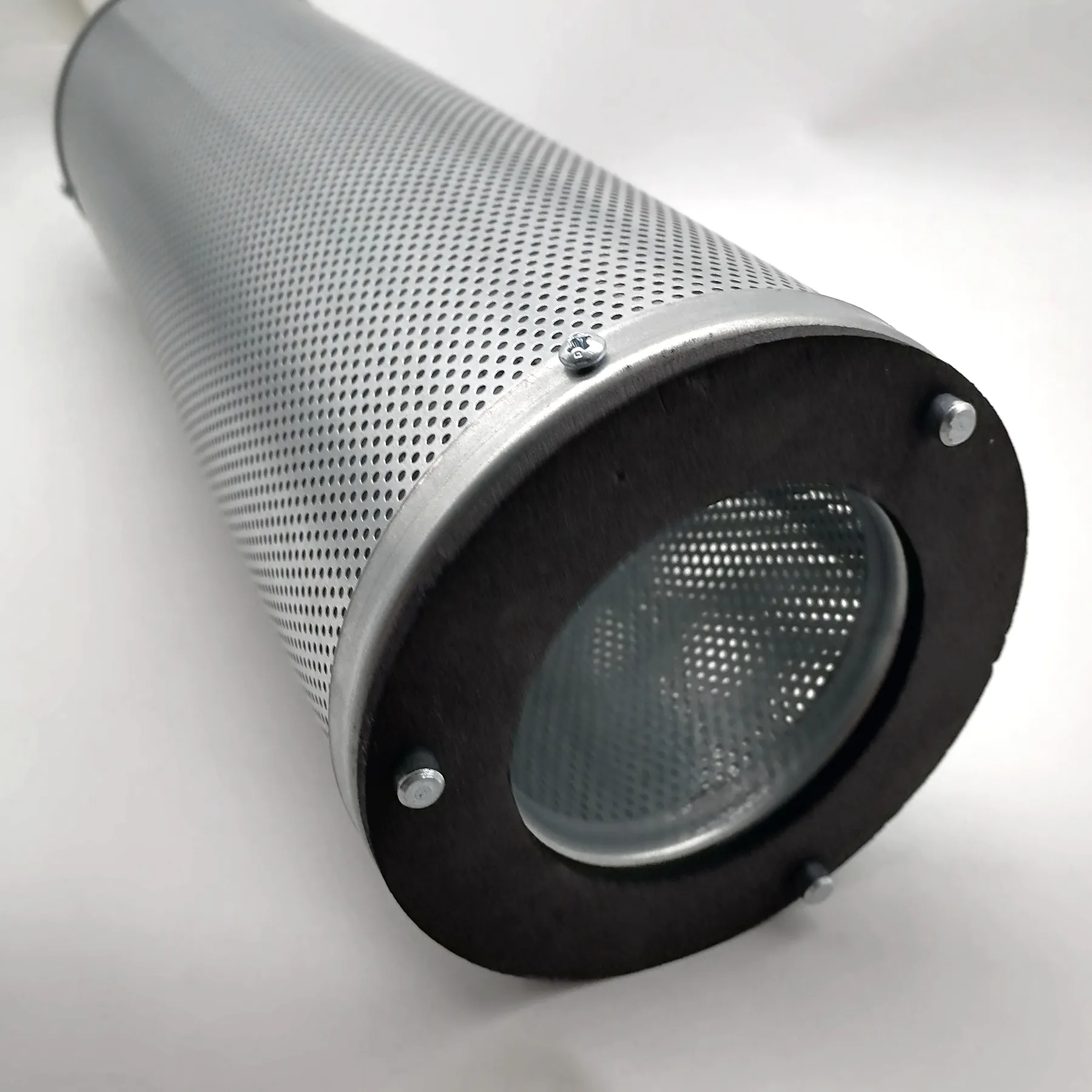

gas turbine filter

The Importance of Gas Turbine Filters

Gas turbines are remarkable machines that play a vital role in power generation, aviation, and various industrial applications. They operate by converting fuel into mechanical energy through a high-temperature combustion process. However, the efficiency and longevity of gas turbines are heavily dependent on the filtration systems that protect their components from harmful contaminants. This is where gas turbine filters come into play.

Gas turbine filters are designed to remove particulate matter, dust, and other impurities from the air before it enters the combustion chamber. Contaminants in the intake air can cause significant damage to the turbine's blades and other critical components. Over time, these pollutants can lead to reduced efficiency, increased maintenance costs, and even catastrophic failures. Therefore, implementing effective filtration systems is crucial for maintaining optimal performance and extending the operational life of gas turbines.

There are several types of filters used in gas turbine applications, including mechanical filters, electrostatic filters, and chemical filters. Mechanical filters utilize physical barriers to trap particles, while electrostatic filters use electrical charges to attract and capture pollutants. Chemical filters, on the other hand, can remove gaseous contaminants. Each type of filter has its advantages and disadvantages, and the choice of filter depends on factors such as the specific operating environment and the type of contaminants expected.

gas turbine filter

One significant advancement in gas turbine filter technology is the development of high-efficiency particulate air (HEPA) filters. These filters can remove 99.97% of particles that are 0.3 micrometers in diameter or larger, making them among the most effective filtration options available. The use of HEPA filters in gas turbines not only improves air quality but also enhances overall turbine performance by ensuring cleaner air for combustion.

Regular maintenance and monitoring of gas turbine filters are also essential. As filters accumulate dust and debris, their efficiency decreases, leading to increased pressure drop across the filter and reduced airflow to the turbine. This can result in a decline in performance and efficiency. It is crucial to establish a routine inspection and replacement schedule to keep the filtration system functioning optimally. Advanced monitoring systems can also provide real-time data on filter performance, helping operators make informed decisions regarding maintenance and replacement.

In conclusion, gas turbine filters are an essential component in the operation of gas turbines. They protect against harmful contaminants, ensuring efficiency and longevity. With advancements in filtration technology and a focus on regular maintenance, operators can maximize the performance and reliability of their gas turbines, making them more effective in meeting the world's growing energy demands. By investing in high-quality filters and implementing best practices in filter management, industries can safeguard their assets and enhance productivity.

-

How to increase the filtration area of pleated dust filter element?NewsMay.13,2025

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

Email:

Email: