Tel:

+8615930870079

Tel:

+8615930870079

ديسمبر . 21, 2024 22:42 Back to list

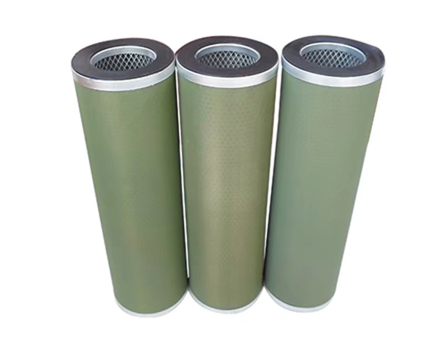

gas turbine air intake filter

Gas Turbine Air Intake Filters Essential for Optimal Performance

Gas turbines play a pivotal role in power generation and various industrial applications, relying heavily on air intake systems. One of the critical components of these systems is the air intake filter, which serves to protect the turbine from contaminants and ensure optimal performance. In this article, we will explore the importance of air intake filters in gas turbines, their types, and maintenance practices, underscoring their vital role in enhancing the efficiency and longevity of gas turbines.

Importance of Air Intake Filters

The primary function of air intake filters in gas turbines is to sift out particulate matter such as dust, dirt, and other contaminants from the air before it enters the turbine. Any foreign debris can cause several issues, including blade erosion, fouling of compressor stages, and overall degradation of performance. These contaminants can lead to reduced efficiency, increased maintenance costs, and potential downtime.

Air quality is crucial for gas turbine performance; a clean intake ensures that the combustion process operates efficiently, producing optimal power output. In fact, studies have shown that even minor decreases in efficiency due to contaminated air can result in significant economic losses over time. Therefore, investing in high-quality air intake filters contributes not just to performance but also to the economic viability of gas turbine operations.

Types of Air Intake Filters

There are several types of air intake filters designed for gas turbines, each with its unique advantages and applications

1. Panel Filters These are the most common type of air filters used in gas turbine applications. They consist of a flat panel made of various filtration media, including fiberglass or synthetic materials. Panel filters are effective at capturing larger particles and are generally easy to replace.

2. Bag Filters Bag filters have a higher dirt-holding capacity compared to panel filters, making them ideal for applications with higher dust concentrations. They have a greater surface area, enabling them to trap more particulates, thus ensuring cleaner air reaches the turbine.

3. Pre-filters Often used as a first line of defense, pre-filters capture larger particles before they reach the main filter. This not only helps extend the life of the primary filter but also reduces the overall load on the filtration system.

gas turbine air intake filter

4. HEPA Filters High-Efficiency Particulate Air (HEPA) filters provide superior filtration, capturing 99.97% of particles that are 0.3 microns or larger. While they are more expensive and may require more frequent replacement, they are excellent for environments with extremely fine particulate matter.

5. Wet Filters These filters use water or other liquids to trap airborne particles. They are often employed in situations where humidity levels are high, as they can also provide additional cooling to the incoming air.

Maintenance of Air Intake Filters

Regular maintenance and monitoring of air intake filters are fundamental to ensuring the longevity and efficiency of gas turbines. Maintenance practices include

- Regular Inspection Filters should be inspected periodically to assess their condition. Visual inspections can reveal signs of clogging or excessive dirt accumulation, indicating the need for replacement.

- Replacement Protocols Establishing a clear protocol for filter replacement can prevent issues associated with clogged filters, such as decreased air intake and reduced turbine efficiency.

- Monitoring Air Quality Using monitoring systems to assess the quality of incoming air can provide valuable data, helping to determine when filters need cleaning or replacement.

- Cleaning Practices For reusable filters, proper cleaning techniques must be employed to ensure their effectiveness. This may include washing or using air blowers, depending on the filter type.

Conclusion

Air intake filters are integral to the efficient operation of gas turbines, safeguarding them against harmful contaminants and ensuring optimal performance. By understanding the different types of filters and implementing effective maintenance practices, operators can enhance the reliability and efficiency of gas turbines. In an era where efficiency and sustainability are paramount, investing in quality air intake filtration systems is not just a best practice—it's a necessity for smooth and cost-effective turbine operation.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: