Tel:

+8615930870079

Tel:

+8615930870079

نوفمبر . 24, 2024 05:37 Back to list

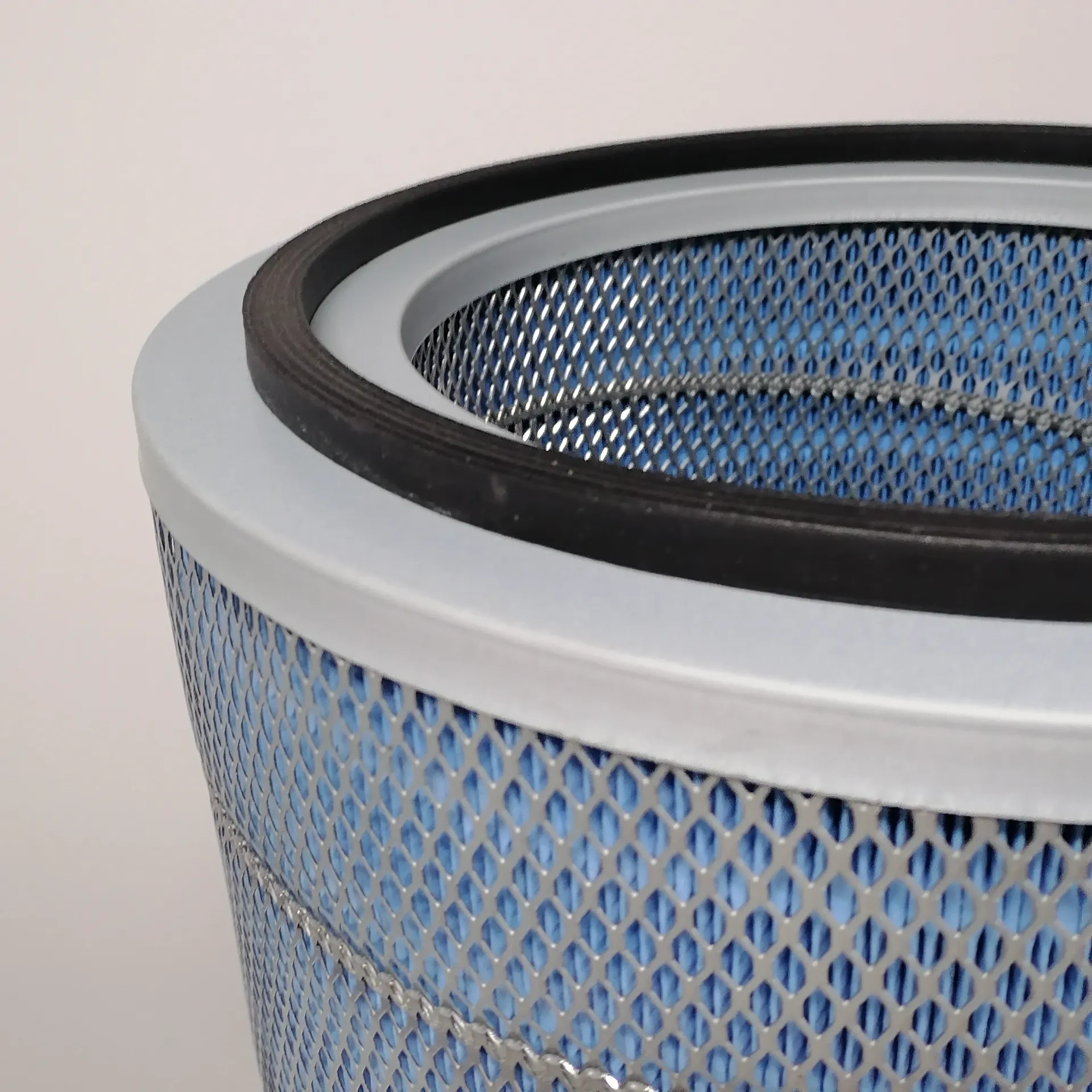

dust extractor pleated filter cartridges

The Importance of Pleated Filter Cartridges in Dust Extractors

In various industrial settings, maintaining a clean and safe environment is crucial for both worker health and operational efficiency. Dust extractors are integral to achieving this, tasked with the removal of airborne particles generated during manufacturing processes. A critical component of these systems is the pleated filter cartridge, which plays a significant role in effectively capturing dust and other pollutants.

What are Pleated Filter Cartridges?

Pleated filter cartridges are designed with a series of folds or pleats, which increase the surface area available for filtration. This unique design enables them to trap dust particles more efficiently as compared to standard filters. The multiple pleats provide a larger filtration area within a compact structure, making them highly effective at capturing fine particulate matter while maximizing airflow. This design is essential for dust extractors, which must operate continuously without a significant drop in performance.

Advantages of Using Pleated Filter Cartridges

1. Enhanced Filtration Efficiency The pleated structure allows for superior dust holding capacity and a smaller pore size, leading to higher efficiency in trapping harmful particles. This is especially important in industries where fine dust can pose health risks to employees or where it can interfere with equipment operations.

2. Longer Service Life Pleated filter cartridges tend to have a longer lifespan than traditional filters. Their larger surface area means they can hold more dust before needing replacement. This not only reduces costs associated with frequent filter changes but also minimizes downtime for maintenance.

dust extractor pleated filter cartridges

3. Lower Energy Consumption As pleated filter cartridges facilitate better airflow, they require less energy for the dust extractor to function. This can lead to significant energy savings over time, making them a more environmentally friendly option compared to other filtering technologies.

4. Versatile Applications These cartridges are suitable for various applications across different industries, including woodworking, metalworking, food production, and pharmaceuticals. Their ability to capture a range of particle sizes makes them invaluable in settings where dust generation is a significant concern.

5. Easy Maintenance Replacing pleated filter cartridges is typically straightforward, allowing for quick maintenance and minimal disruption to operations. Many manufacturers provide user-friendly installation instructions to assist with the replacement process.

Conclusion

In conclusion, pleated filter cartridges are an essential component of dust extraction systems. Their superior design not only enhances filtration efficiency but also contributes to longer service life and lower operational costs. Industries focused on worker safety and equipment longevity can benefit significantly from utilizing dust extractors equipped with pleated filter cartridges. As companies continue to prioritize cleanliness and air quality, investing in high-quality filtration solutions has never been more critical. By choosing the right filtration technology, businesses can ensure a healthier workplace and improve their overall productivity.

In a rapidly progressing industrial landscape, the significance of advanced filtration systems like pleated filter cartridges cannot be overstated. They represent a critical investment in both employee well-being and operational effectiveness, paving the way for safer and more efficient industrial practices.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: