Tel:

+8615930870079

Tel:

+8615930870079

سبتمبر . 19, 2024 15:54 Back to list

High-Performance Pleated Filters for Dust Collectors

The Importance of Dust Collector Pleated Filters in Industrial Applications

In today's industrial landscape, maintaining a clean and safe working environment is paramount. One of the key components in achieving this goal is the dust collector system, particularly the pleated filter. These filters play a crucial role in managing airborne particles, ensuring both operational efficiency and compliance with health and safety regulations.

Dust collectors are essential for capturing dust and particulates generated during various manufacturing processes. They effectively prevent these particles from entering the air and creating unsafe working conditions. Among the various types of filters used in dust collection systems, pleated filters are gaining popularity due to their enhanced filtration efficiency and larger surface area.

The Importance of Dust Collector Pleated Filters in Industrial Applications

Moreover, pleated filters are constructed using advanced materials that provide high filtration efficiency. The synthetic and fiberglass materials used in these filters can effectively capture fine dust particles, including those that are hazardous to human health. For example, in industries dealing with wood, metal, or chemicals, the inhalation of fine dust can lead to serious health issues, such as respiratory problems. Pleated filters help mitigate these risks, promoting better air quality for workers.

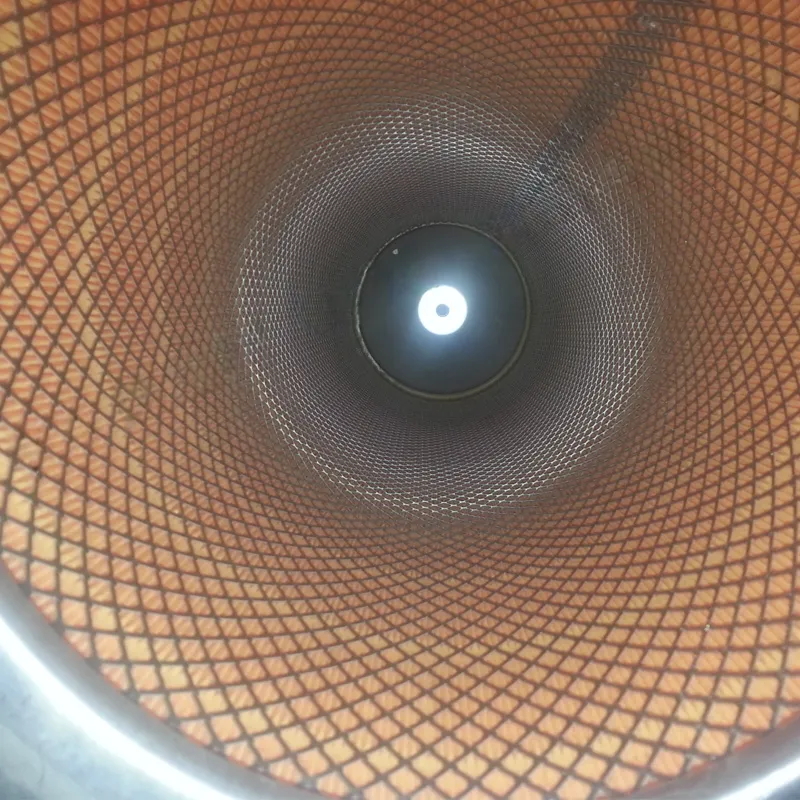

dust collector pleated filter

Efficiency is not the only advantage of pleated filters; they also contribute to energy savings. Because they offer lower resistance to airflow compared to traditional filters, pleated filters help dust collectors operate more efficiently. This can result in reduced energy consumption, which is a significant consideration for industrial facilities aiming to lower operational costs and minimize their environmental footprint.

Furthermore, the versatility of pleated filters makes them suitable for a wide range of applications. They can be used in various industries, from woodworking and metal fabrication to pharmaceuticals and food processing. This adaptability is vital in a manufacturing landscape that often requires tailored solutions to address specific dust challenges.

However, selecting the right pleated filter for a dust collector system involves consideration of several factors. It's crucial to evaluate the specific types of dust being generated, the airflow requirements of the system, and the filter's efficiency rating. Working with experienced suppliers can provide valuable insights into the best filter options that meet the unique needs of a facility.

In conclusion, dust collector pleated filters are indispensable in maintaining a safe and efficient industrial environment. Their enhanced filtration capabilities, energy efficiency, and versatility make them an ideal choice for a variety of applications. By investing in quality pleated filters, industries can not only protect the health of their employees but also improve operational efficiency and reduce costs in the long run. As the demand for effective dust management solutions continues to grow, pleated filters will undoubtedly play a central role in achieving cleaner, safer workplaces across the globe.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: