Tel:

+8615930870079

Tel:

+8615930870079

أكتوبر . 16, 2024 23:10 Back to list

cartridge vacuum filter

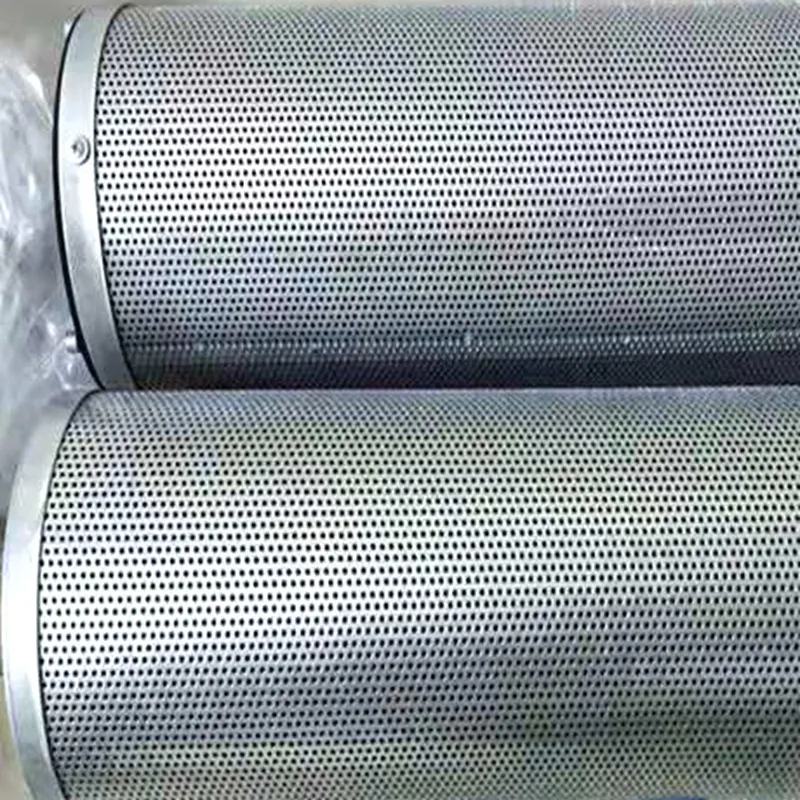

Understanding Cartridge Vacuum Filters Principles and Applications

Cartridge vacuum filters are a crucial component in various industries, serving as effective solutions for liquid-solid separation. Their design and operational efficiency make them suitable for a wide range of applications, including wastewater treatment, food and beverage processing, pharmaceuticals, and even the mining industry. This article explores the principles behind cartridge vacuum filters, their construction, advantages, and applications.

Basic Principles of Cartridge Vacuum Filters

At its core, a cartridge vacuum filter operates on the principle of creating a vacuum that pulls liquid through a filter medium, separating solids from liquids. The filter cartridges are typically cylindrical in shape and contain a porous medium that traps solid particles while allowing liquids to pass through. This process occurs in a closed system where a vacuum is generated typically by a mechanical pump, enhancing the filtration efficiency.

Construction of Cartridge Vacuum Filters

Cartridge vacuum filters are composed of several key components

1. Filter Cartridges These are replaceable units designed to increase the surface area available for filtration. They can be made from various materials, including paper, cloth, or polymer, depending on the intended application and the nature of the fluid being filtered.

2. Vacuum Chamber This is the section of the filter that holds the filter cartridges and where the vacuum is created. The design of the chamber is essential for maintaining the desired flow dynamics and ensuring even distribution of the fluid across the filtration surface.

3. Feed Pump This component supplies the liquid to the filter and is responsible for maintaining a consistent flow rate. The selection of an appropriate pump is critical for optimizing the filtration process without causing excessive pressure buildup.

4. Control System Modern cartridge vacuum filters often integrate automated control systems that monitor pressure, flow rate, and other operational parameters. This automation ensures efficiency and helps to prevent issues such as clogging or over-pressurization.

Advantages of Cartridge Vacuum Filters

Cartridge vacuum filters offer several advantages, making them a popular choice in various industries

cartridge vacuum filter

- High Efficiency The vacuum pressure enhances the filtration rate, allowing for quick processing of large volumes of liquid. This efficiency leads to reduced operational time and costs.

- Versatile Applications Due to their modular design, cartridge filters can be tailored to different filtration needs, accommodating various solid particle sizes and concentrations.

- Easy Maintenance The replaceable nature of the filter cartridges simplifies maintenance, as they can be quickly exchanged without significant downtime for the system.

- Space-Saving Design Cartridge vacuum filters often have a smaller footprint compared to other filtration systems, making them ideal for facilities with space constraints.

Applications of Cartridge Vacuum Filters

Cartridge vacuum filters find utility in diverse applications across industries

1. Wastewater Treatment They are employed to treat industrial and municipal wastewater, effectively removing suspended solids and contaminants before the water is released or reused.

2. Food and Beverage Industry In this sector, cartridge filters are used to clarify juices, wines, and other beverages, ensuring product purity and safety.

3. Pharmaceuticals In pharmaceutical manufacturing, cleanliness is paramount. Cartridge vacuum filters help maintain sterile conditions by effectively filtering out contaminants.

4. Mining and Metal Processing In the mining industry, they separate valuable minerals from slurries, enhancing recovery rates while minimizing environmental impact.

Conclusion

Cartridge vacuum filters represent a vital technology in the field of liquid-solid separation. Their efficient design and operational capabilities make them suitable for a multitude of applications across various industries. As businesses continue to prioritize efficiency and sustainability, the role of cartridge vacuum filters is likely to grow, further solidifying their importance in modern filtration systems. By understanding their principles, construction, advantages, and applications, industries can better appreciate and utilize these invaluable tools for their specific needs.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: