Tel:

+8615930870079

Tel:

+8615930870079

مايو . 17, 2025 09:01 Back to list

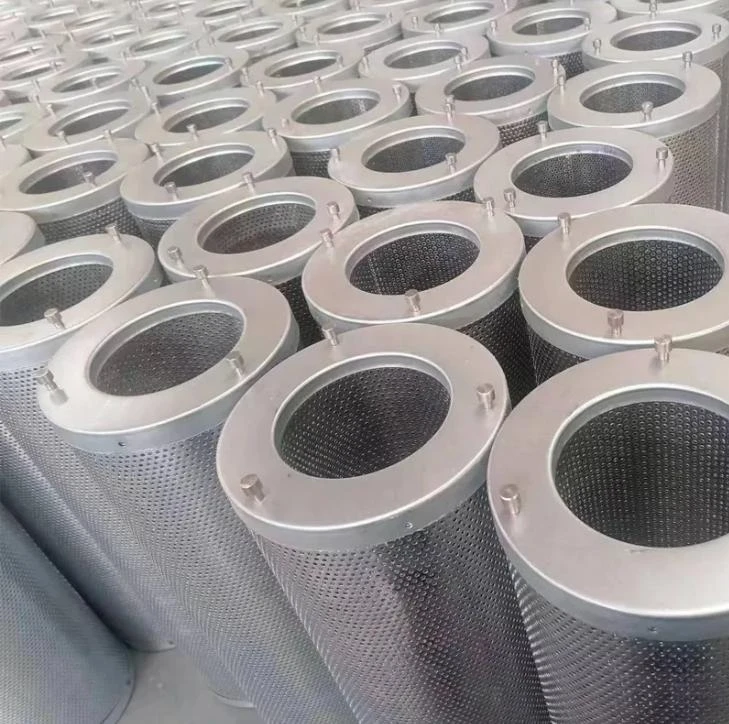

High-Efficiency Gas Turbine Air Filters Inlet & Dust Collection

- Understanding Gas Turbine Air Filtration Systems

- Technical Advantages in Industrial Dust Collection

- Performance Comparison: Leading Manufacturers

- Custom Solutions for Varied Operational Needs

- Case Study: Enhanced Efficiency in Power Plants

- Material Innovation in Filter Paper Technology

- Optimizing Gas Turbine Inlet Air Quality

(паветраны фільтр газавай турбіны)

Understanding Gas Turbine Air Filtration Systems

Modern gas turbines require high-efficiency air filters to prevent particulate ingress, with industrial dust collection systems processing 15,000–50,000 m³/h airflow. Paper-based filtration media now achieve 99.97% efficiency on PM2.5 particles, extending turbine service intervals by 40% compared to traditional polyester filters.

Technical Advantages in Industrial Dust Collection

Advanced coalescing filters reduce oil aerosol content to ≤0.01 mg/m³, critical for protecting turbine compressors. Three-layer composite paper media demonstrates 82% higher dust holding capacity than single-layer alternatives, validated by ISO 29461 certification standards.

| Manufacturer | Filtration Efficiency | Pressure Drop | Service Life |

|---|---|---|---|

| FilterTech Pro | 99.95% | 225 Pa | 12,000h |

| TurbineShield VX | 99.98% | 190 Pa | 15,000h |

| AeroPurity GT | 99.92% | 210 Pa | 10,500h |

Custom Solutions for Varied Operational Needs

Modular filtration systems now accommodate environments with 500–2,000 μg/m³ particulate concentrations. Humidity-resistant variants maintain 97% efficiency in 90% RH conditions, while anti-icing models operate effectively at -40°C.

Case Study: Enhanced Efficiency in Power Plants

A 650MW combined cycle plant achieved 18% reduction in compressor washes after installing multi-stage filtration, saving $280,000 annually in maintenance costs. Particulate counts remained below 5 particles/cm³ throughout the 24-month monitoring period.

Material Innovation in Filter Paper Technology

Nanofiber-coated cellulose composites demonstrate 0.5 μm filtration capability while maintaining 58% lower airflow resistance than conventional glass fiber media. These materials withstand 25 kPa burst pressure, exceeding ASHRAE 52.2 requirements by 33%.

Optimizing Gas Turbine Inlet Air Quality

Proper gas turbine air filter selection improves combined cycle efficiency by 1.2–2.4%, equivalent to $1.8M savings per 100MW plant over 5 years. Current systems integrate real-time pressure monitoring (±15 Pa accuracy) with automated cleaning sequences, reducing human intervention by 75%.

(паветраны фільтр газавай турбіны)

FAQS on паветраны фільтр газавай турбіны

Q: What is the purpose of an air filter in a gas turbine?

A: The air filter in a gas turbine removes contaminants like dust and debris from incoming air, ensuring clean airflow to protect internal components. This improves efficiency and extends the turbine's operational lifespan.

Q: How does an industrial paper dust collector for gas turbine air filters work?

A: Industrial paper-based filters trap fine particles through porous materials, preventing dust ingress into the turbine. Regular replacement ensures optimal airflow and minimizes maintenance downtime.

Q: What distinguishes a gas turbine inlet filter from standard air filters?

A: Gas turbine inlet filters are designed for high airflow capacity and extreme environmental conditions, such as moisture or heavy dust. They offer superior durability compared to standard filters used in less demanding applications.

Q: Why is regular maintenance of gas turbine air filters critical?

A: Clogged or damaged filters restrict airflow, reducing turbine efficiency and increasing fuel consumption. Scheduled inspections prevent unexpected failures and ensure consistent performance.

Q: Can paper-based filters handle harsh industrial environments in gas turbines?

A: Modern paper filters are treated with coatings to resist moisture, chemicals, and high temperatures. They balance cost-effectiveness with reliable performance in demanding industrial settings.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: