Tel:

+8618931101301

Tel:

+8618931101301

نومبر . 19, 2024 00:11 Back to list

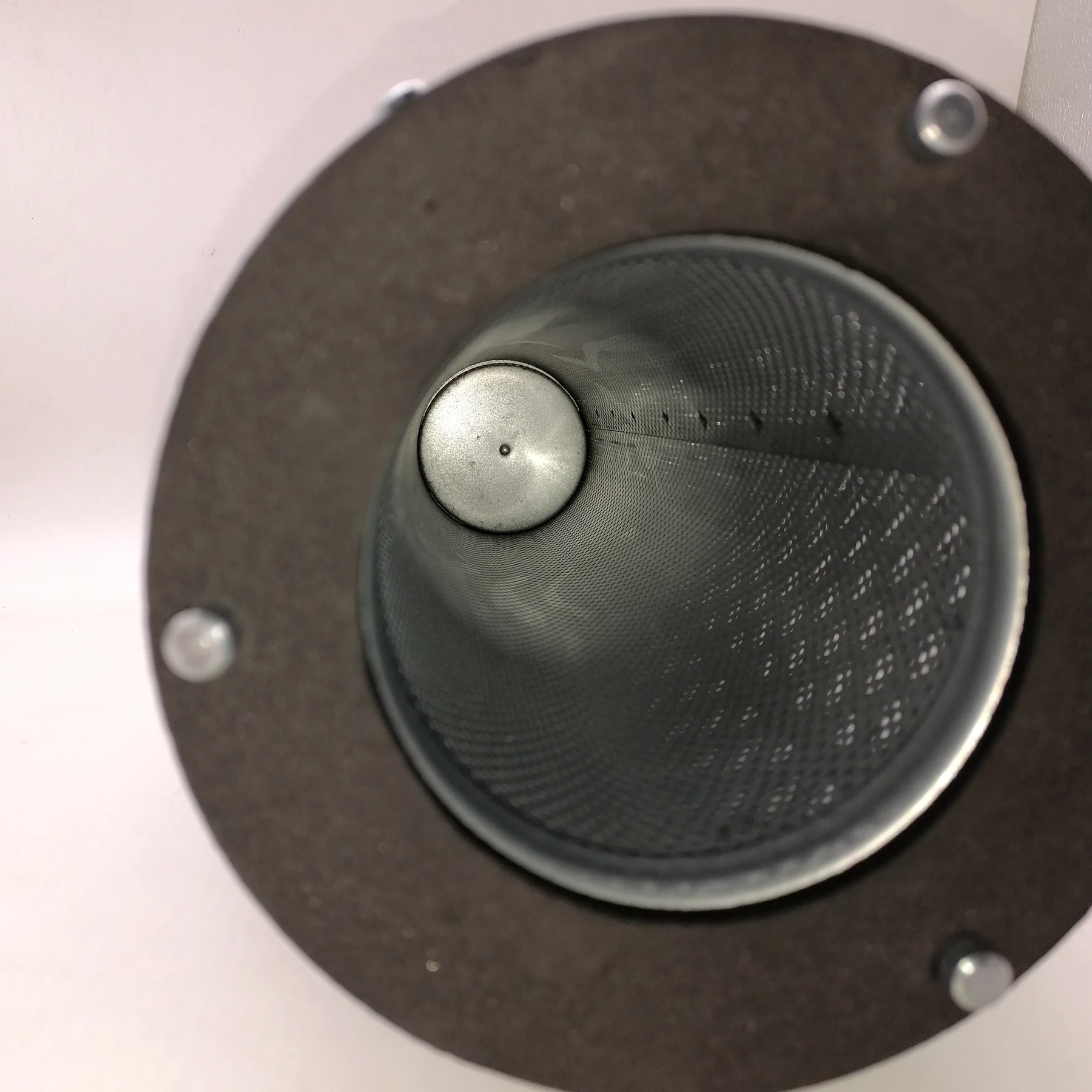

vacuum filter cartridge

Understanding Vacuum Filter Cartridges An Essential Component in Filtration Systems

In various industrial and laboratory settings, the need for efficient filtration of liquids is paramount. One of the key components in many filtration systems is the vacuum filter cartridge. This device plays a crucial role in separating solids from liquids, ensuring the purity and quality of the filtered product.

What is a Vacuum Filter Cartridge?

A vacuum filter cartridge is a cylindrical component that houses filtration media designed to operate under a vacuum. It functions by creating a suction effect that draws liquid through the filter medium, allowing solid particles to be retained while the filtered liquid passes through. This process not only enhances the efficiency of liquid separation but also speeds up filtration times compared to gravity-fed systems.

Components and Design

The design of vacuum filter cartridges can vary significantly based on their intended application, but they generally consist of several key components

1. Filter Medium The core of the cartridge, this can be made from various materials including polyester, polypropylene, or cellulose. The choice of filter medium depends on the specific solids being filtered and the desired filtration rate.

2. Cartridge Housing This is the outer shell that encases the filter medium. It often features ports for input and output connections, allowing for seamless integration into existing filtration systems.

3. Seal To ensure that all the wastewater goes through the filter without bypassing, cartridges are fitted with seals that prevent leaks.

4. End Plates These are fixtures at both ends of the cartridge that provide structural integrity and facilitate connection to the filtration system.

vacuum filter cartridge

Applications and Benefits

Vacuum filter cartridges are widely used across various industries, including pharmaceuticals, chemicals, food and beverage, and wastewater treatment. Some of their key benefits include

- Efficiency The vacuum mechanism enhances the filtration speed, making it ideal for high-throughput applications.

- Consistency They offer reliable and repeatable results, which is crucial in industries where product quality must be maintained.

- Space-saving Design Many vacuum filter cartridges are designed to fit into compact spaces, making them suitable for installations with limited room.

- Versatility They can be adapted for different liquid and solid combinations, allowing for the use of customized filtration media based on specific requirements.

Maintenance and Care

While vacuum filter cartridges are designed for durability, regular maintenance is essential to ensure their longevity and optimal performance. Routine inspection for wear and tear, proper sealing, and timely replacement are critical. Contaminated or clogged filters can lead to inefficient operation and poor filtration quality, which ultimately affects the entire process.

Conclusion

In summary, vacuum filter cartridges are indispensable tools in various filtration applications, offering a combination of speed, efficiency, and reliability. By understanding their components, benefits, and maintenance requirements, industries can harness the full potential of these cartridges to improve their filtration processes. As technology advances, we can expect even more innovations in filtration solutions, further enhancing the role of vacuum filter cartridges in safeguarding product quality across sectors.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: