Tel:

+8618931101301

Tel:

+8618931101301

نومبر . 07, 2024 13:41 Back to list

Understanding the Functionality and Benefits of Vacuum Cartridges in Various Applications

Understanding Vacuum Cartridge Technology Functionality and Applications

In today’s rapidly evolving technological landscape, vacuum cartridge technology plays a crucial role in various industries, from automotive engineering to consumer electronics. At its core, a vacuum cartridge is a device that operates using the principle of vacuum to create an environment that can significantly enhance performance, longevity, and reliability. This article delves into the functionalities, components, and applications of vacuum cartridges, providing a comprehensive overview of this vital technology.

What is a Vacuum Cartridge?

A vacuum cartridge is a sealed container that maintains a vacuum state within its internal environment. This vacuum is achieved by removing air and gases, thereby creating a pressure difference that allows for better functionality of the devices in which it is used. The maintenance of a vacuum reduces the occurrence of oxidation, corrosion, and other detrimental reactions that can occur in the presence of air. Most vacuum cartridges are designed to operate under various pressures and temperatures, making them versatile in their applications.

Key Components of Vacuum Cartridges

1. Sealing Mechanism The integrity of a vacuum cartridge relies on its sealing mechanisms, which are designed to withstand the external atmospheric pressure. Common materials used for seals include elastomers, metals, and specialized polymers, each chosen based on the specific operational environment.

2. Inner Chamber The inner chamber is where the vacuum is maintained. The design of this chamber ensures minimal thermal conduction and optimal material properties to reduce potential outgassing, which can degrade performance.

3. Vacuum Pump Interface To create and maintain the vacuum, a vacuum pump is typically connected to the cartridge. This interface is crucial for achieving the desired vacuum level and is engineered to ensure leakage is minimized during the pumping process.

4. Sensors and Monitoring Devices Many advanced vacuum cartridges are equipped with sensors to monitor pressure and temperature. This enables real-time data collection, ensuring that the cartridge remains within safe operational limits and enhancing reliability.

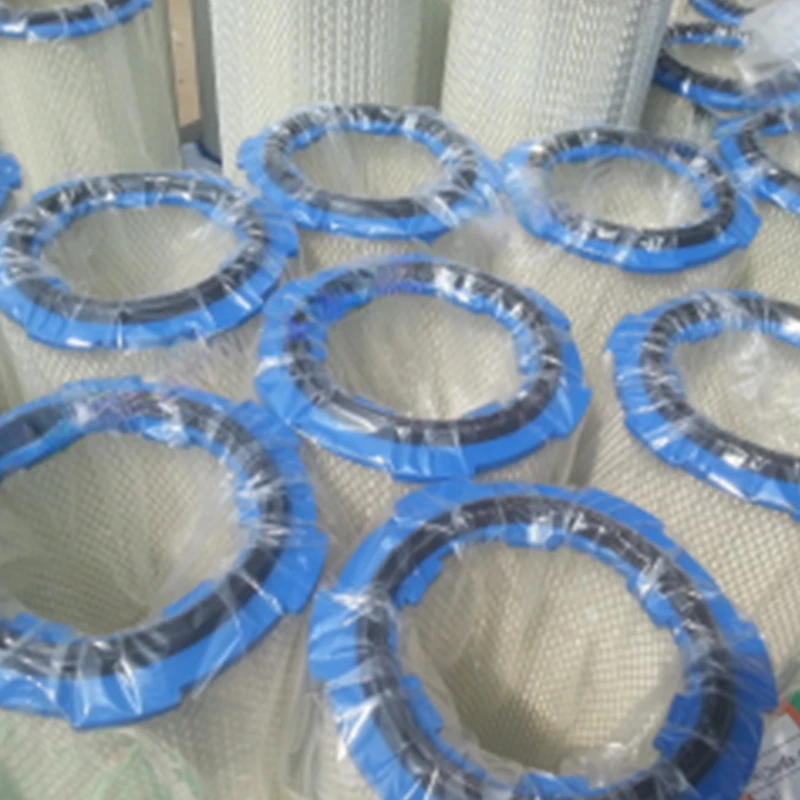

vacuum cartridge

Applications of Vacuum Cartridges

1. Automotive Industry Vacuum cartridges are commonly used in vehicle braking systems, where they provide the necessary force to amplify braking effort. The efficiency of these systems is critical, as they enhance vehicle safety and responsiveness.

2. Consumer Electronics In electronic devices, vacuum cartridges are used for sealed environments to protect sensitive components. For instance, in some high-performance audio devices, vacuum technology is employed to minimize sound distortion and enhance acoustic quality.

3. Medical Devices In the medical field, vacuum cartridges are essential for devices like syringes and clinical instruments where precise pressure control is required. They ensure sterility and maintain the efficacy of the contents during storage and transportation.

4. Food Packaging Vacuum cartridges are also pivotal in food preservation. By removing air from packaging, these cartridges extend shelf life, prevent spoilage, and preserve flavor and nutritional value.

The Future of Vacuum Cartridge Technology

As industries continue to innovate, the demand for more efficient and reliable vacuum cartridges is on the rise. Future advancements may include the development of smart vacuum cartridges equipped with IoT technology, enabling predictive maintenance and enhanced user control. Additionally, the use of advanced materials and nanotechnology could further improve the performance and durability of these systems.

In conclusion, vacuum cartridge technology is a remarkable innovation that serves as a backbone for numerous applications across different sectors. Understanding its components and functionality highlights its essential role in enhancing device performance, safety, and reliability. As technology progresses, vacuum cartridges are set to become even more integral to our daily lives, ensuring efficiency and effectiveness in various applications.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: