Tel:

+8615930870079

Tel:

+8615930870079

دسمبر . 16, 2024 15:54 Back to list

Optimizing Air Intake Filters for Turbine Efficiency and Performance Enhancement

The Importance of Turbine Air Intake Filters

In the realm of aerospace and industrial applications, the efficiency and reliability of turbines are paramount. Turbine air intake filters play a critical role in ensuring that these systems operate optimally. These filters serve as the first line of defense against contaminants that can compromise turbine performance, leading to potential failures and costly downtime. This article delves into the importance, functionality, and maintenance of turbine air intake filters.

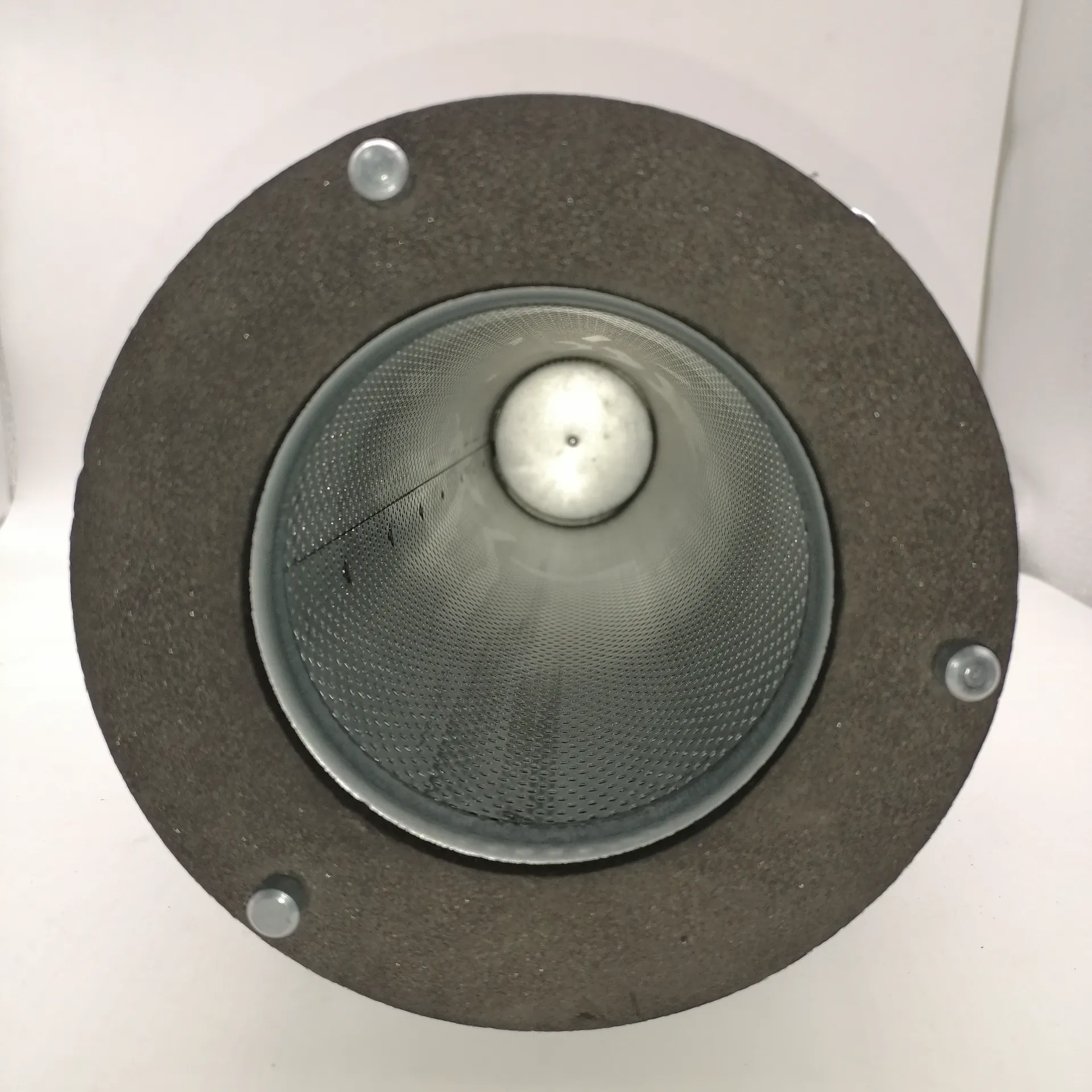

Understanding Turbine Air Intake Filters

Turbine air intake filters are specially designed filtration systems that prevent dirt, dust, debris, and other pollutants from entering turbine engines. Turbines, whether used in jet propulsion or power generation, rely on vast amounts of air to operate effectively. Clean air is crucial for maintaining the correct air-fuel ratio, ensuring combustion efficiency, and maximizing performance. Without adequate filtration, contaminants can disrupt engine operation and lead to inefficiencies.

Types of Contaminants

Contaminants that can affect turbine performance vary widely, ranging from large particles like sand and gravel to smaller pollutants such as pollen, smoke, and industrial emissions. Each type of contaminant can lead to different problems. For example, larger particles can cause physical damage to turbine blades, while smaller particles may result in fouling, which affects the engine's efficiency and operational lifespan.

The Mechanism of Filtration

Turbine air intake filters operate through various methods. Common types include mechanical filters, electrostatic filters, and specialized media such as carbon filters designed for specific applications. Mechanical filters work by trapping particles in their fibrous structure, while electrostatic filters use an electrical charge to attract and hold contaminants. Advanced filtration technologies often combine these methods to offer superior performance.

turbine air intake filters

When designing an air intake filter system, several factors need to be considered, including the operating environment, the size of particles being captured, flow rates, and the pressure drop across the filter. A well-engineered filter system can significantly extend the lifespan of the turbine and improve overall efficiency.

The Impact on Performance

The effects of inadequate filtration can be devastating. Entry of pollutants can lead to wear and tear on turbine components, resulting in reduced efficiency and increased fuel consumption. Studies have shown that even minor contamination can lead to performance losses of several percentage points, which is crucial in high-stakes environments such as aviation and energy production. Furthermore, the economic implications of downtime due to turbine repairs or replacements can be substantial, underscoring the necessity for effective air intake filtration.

Maintenance and Replacement

Regular maintenance and timely replacement of turbine air intake filters are crucial for sustaining performance. Operators must establish protocols to inspect and replace filters based on usage and environmental conditions. Dirty or clogged filters can lead to increased pressure drops even before reaching their maximum capacity, resulting in decreased airflow and engine performance issues.

Moreover, advancements in monitoring technology have made it easier for operators to track the condition of filters in real time. Using pressure gauges and airflow sensors, operators can receive notifications when filters are nearing their limit, allowing for proactive maintenance. This not only enhances reliability but also reduces operational costs.

Conclusion

In conclusion, turbine air intake filters are an essential component in the operation of turbine engines across various industries. Their role in ensuring clean air intake cannot be overstated, as it directly affects performance, efficiency, and the operational lifespan of the turbine. Regular maintenance and advancements in filtration technologies are key to optimizing turbine operations and minimizing costs. By investing in high-quality air intake filters and establishing rigorous maintenance protocols, operators can safeguard the performance of their turbine systems, ensuring that they operate effectively in a clean and contaminant-free environment.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: