Tel:

+8615930870079

Tel:

+8615930870079

دسمبر . 25, 2024 16:44 Back to list

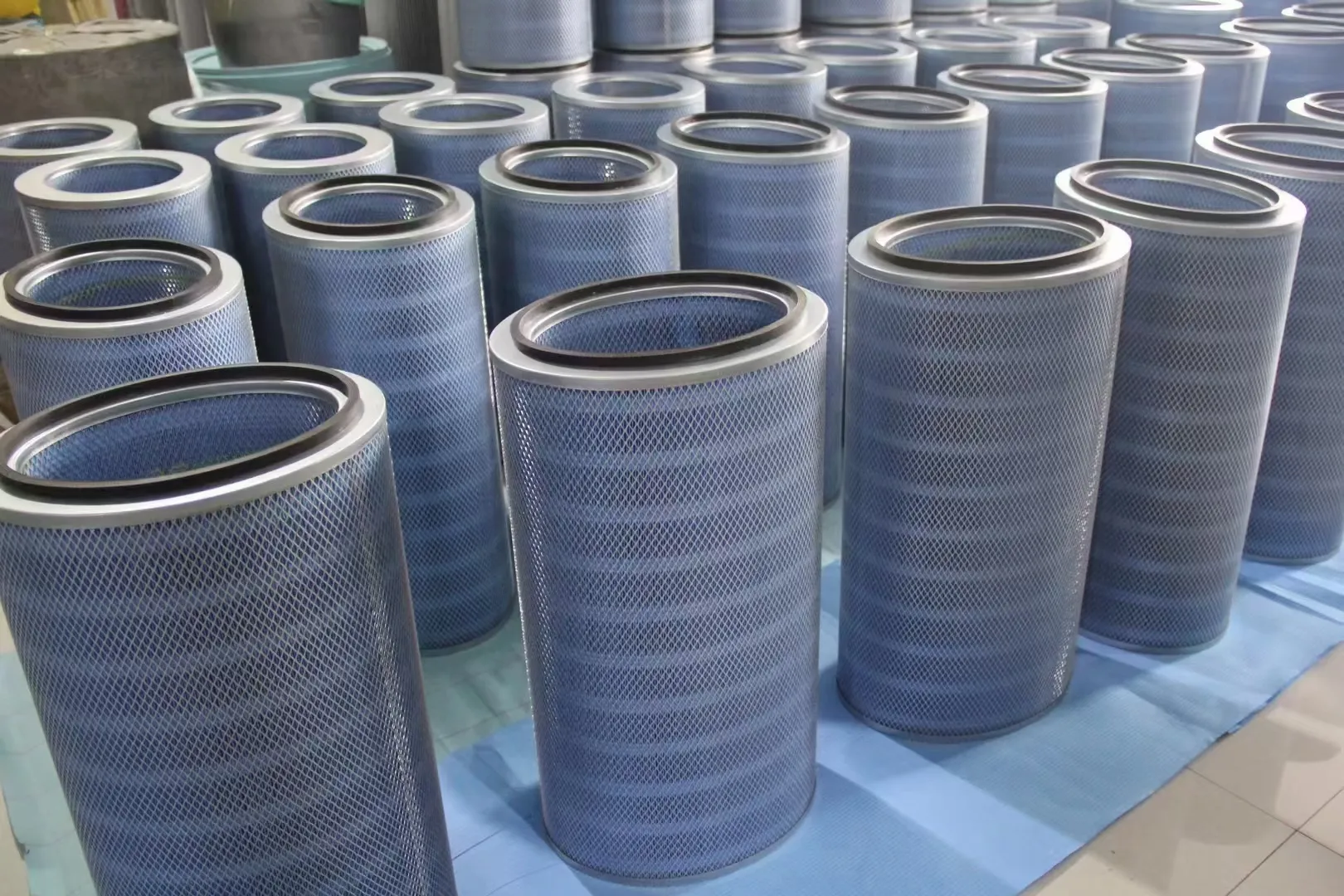

metal filter cartridge

Understanding Metal Filter Cartridges An In-depth Overview

Metal filter cartridges are essential components in various industrial applications, particularly in the fields of oil and gas, pharmaceuticals, food processing, and water treatment. These cartridges are designed to filter out contaminants and impurities, ensuring the purity and quality of the fluids being processed. This article aims to explore the significance, types, advantages, applications, and maintenance of metal filter cartridges.

What Are Metal Filter Cartridges?

Metal filter cartridges are specialized filtration devices made from various metals, including stainless steel, aluminum, and nickel alloys. Unlike traditional paper or cloth filters, metal cartridges are durable, reusable, and capable of withstanding extreme temperatures and pressures. Their design often features a porous structure that allows fluids to pass through while trapping particulate matter, mechanically preventing contaminants from entering the system.

Types of Metal Filter Cartridges

Metal filter cartridges can be classified based on their construction, the filtration mechanism used, and the specific application for which they are intended. The most common types include

1. Pore Size-Based Filters These filters have specific pore sizes, allowing them to capture particles of a certain diameter. They are typically used in applications where precise filtration is critical.

2. Coalescing Filters These filters are designed to separate immiscible liquids, such as oil and water. They facilitate the removal of water from fuel or oil, preventing contamination of the final product.

3. Strainers Often used in applications where larger particles need to be filtered out, strainers protect sensitive equipment by capturing debris that could cause damage or malfunction.

4. Mesh Filters Constructed from woven metal fibers, mesh filters provide excellent strength and are reusable. They are particularly useful in applications involving coarse filtration or high flow rates.

Advantages of Metal Filter Cartridges

The use of metal filter cartridges over traditional filtering methods offers several advantages

1. Durability Metal filters are highly resistant to corrosion, heat, and pressure, making them ideal for harsh environments where standard filters may fail.

2. Reusable Unlike disposable filters, metal cartridges can be cleaned and reused multiple times, leading to significant cost savings over time.

metal filter cartridge

4. Low Maintenance Their robust nature means metal filter cartridges typically require less frequent replacements, resulting in lower maintenance efforts.

5. Environmental Benefits By opting for reusable metal cartridges, industries can reduce waste and their overall environmental footprint.

Applications of Metal Filter Cartridges

Metal filter cartridges are used across diverse industries, including

1. Oil and Gas In these sectors, metal filters ensure the integrity of fuels and lubricants by removing sediments, particulates, and water.

2. Pharmaceuticals They are crucial in maintaining the sterility and purity of products by filtering out harmful agents from solvents and raw materials.

3. Food and Beverage Metal filters help in clarifying liquids and ensuring that food products meet safety standards by eliminating potential contaminants.

4. Water Treatment They are used in municipal and industrial water treatment facilities to purify water and remove harmful substances.

Maintenance of Metal Filter Cartridges

To ensure optimal performance and longevity of metal filter cartridges, regular maintenance is essential. This includes

1. Cleaning Depending on the application, cartridges may need to be cleaned periodically to remove trapped particles. Methods such as ultrasonic cleaning or backwashing can effectively restore their functionality.

2. Inspection Regular checks for signs of wear, corrosion, or damage help in identifying when a cartridge needs replacement.

3. Proper Storage When not in use, metal cartridges should be stored in a clean, dry environment to prevent contamination and deterioration.

Conclusion

Metal filter cartridges play a vital role in various industrial processes by providing effective filtration solutions. Their durability, efficiency, and environmental benefits make them a preferred choice for many applications. Understanding their types, advantages, and maintenance can help industries optimize their operations, ensuring the quality and safety of their products while reducing costs and environmental impact. As technology advances, metal filter cartridges will continue to evolve, offering even more innovative solutions for filtration needs.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: