Tel:

+8615930870079

Tel:

+8615930870079

اکتوبر . 02, 2024 02:11 Back to list

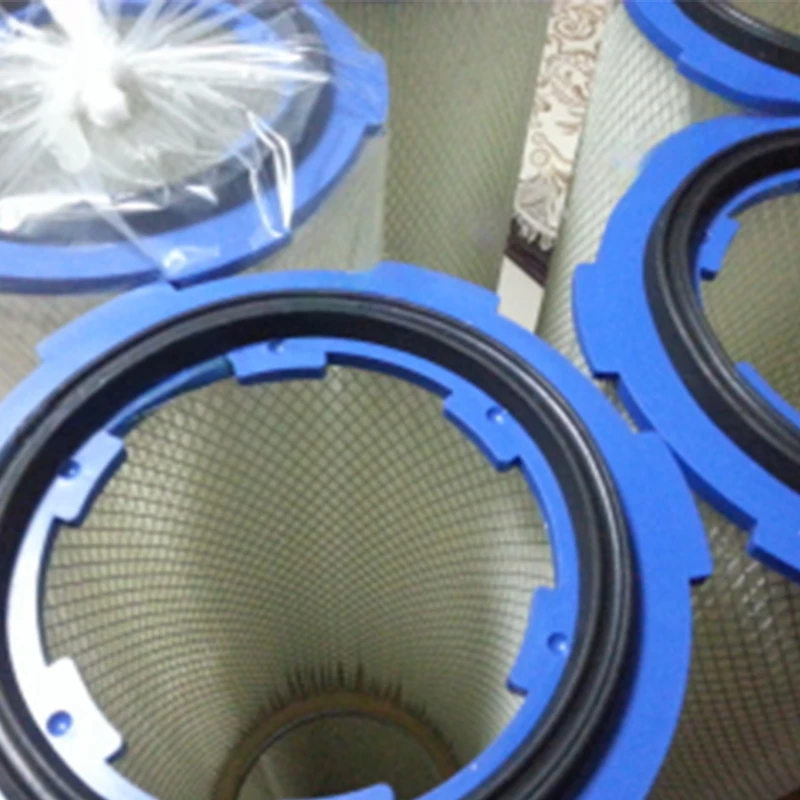

High Efficiency Metal Filter Cartridge for Superior Filtration Solutions

Understanding Metal Filter Cartridges Key Features and Benefits

In the world of industrial filtration, metal filter cartridges play a crucial role in maintaining the purity and quality of liquids and gases. These sophisticated filtration systems are designed to remove particulates, contaminants, and impurities, ensuring that processes run smoothly and efficiently. This article explores the various aspects of metal filter cartridges, their advantages, and their applications in different industries.

What Are Metal Filter Cartridges?

Metal filter cartridges are highly durable filtration devices typically made from various metals such as stainless steel, aluminum, or other alloys. They are designed to accommodate a wide range of filtration processes, including liquid and gas filtration. The cartridges feature a mesh or porous structure that allows for the effective trapping of unwanted particles while permitting the flow of clean fluid or gas.

Key Features

1. Durability One of the most significant advantages of metal filter cartridges is their resilience. Unlike their polymer or paper counterparts, metal filters can withstand extreme temperatures and pressures, making them ideal for harsh industrial environments. This durability also translates to a longer lifespan, reducing the need for frequent replacements.

2. Chemical Resistance Metal filter cartridges are often resistant to a variety of chemicals, enabling them to be used in diverse applications, including petrochemical processing, food and beverage production, and pharmaceuticals. Their ability to resist corrosion and degradation extends their applicability across different industries.

3. Reusability Many metal filter cartridges can be cleaned and reused, further enhancing their cost-effectiveness and sustainability. Depending on the design and filter media, users can employ various cleaning methods, including backwashing or ultrasonic cleaning, to remove accumulated debris, thus prolonging the life of the cartridge.

4. High Filtration Efficiency Metal filter cartridges offer superior filtration capabilities, capturing particles as small as a few microns. This high level of efficiency helps to maintain product quality by reducing contamination risks and ensuring compliance with industry standards.

metal filter cartridge

5. Customizability Manufacturers often provide options for customizing metal filter cartridges to meet specific application requirements. This includes varying mesh sizes, shapes, and filter thicknesses, allowing users to optimize their filtration processes based on the specific needs of the fluid or gas involved.

Applications in Various Industries

Metal filter cartridges are versatile and find applications across a broad spectrum of industries

- Food and Beverage In the production of food and beverages, maintaining a high level of cleanliness is critical. Metal filters ensure that no unwanted particles contaminate the final product.

- Pharmaceuticals The pharmaceutical industry demands the highest level of purity in its processes. Metal filter cartridges help meet stringent regulatory standards by effectively removing contaminants.

- Oil and Gas In oil and gas applications, these filters protect equipment from damage caused by particulate contamination, ensuring smooth operations and prolonging the life of costly machinery.

- Chemical Processing In chemical manufacturing, metal filters are essential for separating solids from liquids, safeguarding the integrity of chemical reactions.

Conclusion

Metal filter cartridges represent a critical component in many industrial filtration systems. Their unique combination of durability, chemical resistance, reusability, and high filtration efficiency makes them an ideal choice for a myriad of applications. By selecting the right metal filter cartridge for specific processes, industries can not only enhance the quality of their products but also achieve substantial efficiencies in operations, ultimately contributing to a cleaner and safer environment.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: