Tel:

+8618931101301

Tel:

+8618931101301

اکتوبر . 16, 2024 06:20 Back to list

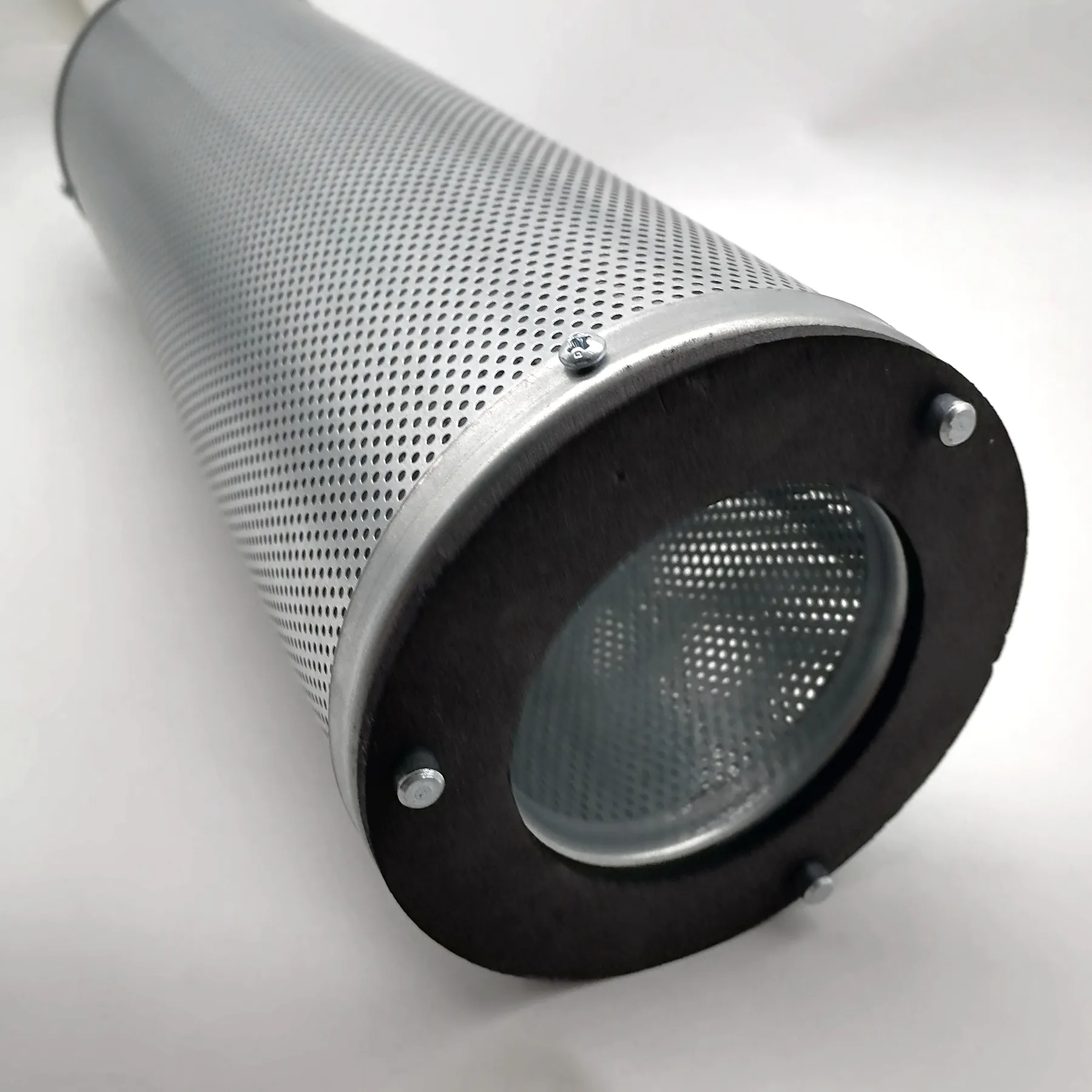

High-Efficiency Cartridge Filters for Industrial Dust Collection Systems

Industrial Dust Collector Cartridge Filters An Essential Component in Workplace Safety

In today’s industrial landscape, the management of airborne pollutants is paramount for both compliance with regulations and the health of workers. Among the various solutions tailored to address this issue, industrial dust collector cartridge filters have emerged as a critical component in air pollution control systems.

Understanding Dust Collector Cartridge Filters

Dust collector cartridge filters are specially designed filtration systems that capture particulate matter from industrial processes. These filter cartridges are constructed from robust materials designed to withstand harsh environments while effectively collecting dust, smoke, and other particulate contaminants. Unlike traditional bag filters, cartridge filters offer a greater surface area, allowing for efficient airflow and higher dust-holding capacity.

The Importance of Dust Collection

Work environments in industries such as manufacturing, pharmaceuticals, and food processing often produce dust that poses risks to both workers and machinery. Prolonged exposure to airborne dust can lead to serious respiratory problems, reduced visibility, and even explosive conditions in certain situations. Furthermore, accumulated dust on machinery can lead to breakdowns and increased maintenance costs, negatively impacting productivity.

Implementing a dust collection system equipped with high-quality cartridge filters helps mitigate these risks, ensuring cleaner air and a safer workplace. Moreover, regulatory bodies impose strict guidelines regarding air quality, necessitating the adoption of effective filtration systems to maintain compliance.

Features of Cartridge Filters

The design of cartridge filters offers several distinctive features that enhance their effectiveness. These include

1. High Filtration Efficiency Cartridge filters can capture small particles, often down to 0.5 microns, ensuring that the vast majority of contaminants are removed from the air stream.

2. Longer Service Life Due to their larger surface area, cartridge filters can hold more dust, leading to longer maintenance intervals and reduced replacement costs.

industrial dust collector cartridge filters

4. Easy Installation and Maintenance Cartridge filters are designed for easy installation, replacement, and cleaning, minimizing downtime and labor costs.

5. Reduced Emissions By effectively capturing dust before it is released into the atmosphere, cartridge filters play a pivotal role in decreasing overall emissions, supporting environmental sustainability initiatives.

Choosing the Right Cartridge Filter

Selecting the appropriate cartridge filter involves considering several factors

- Particle Size and Composition Understanding the specific type of dust generated in your industry is crucial. Different materials require different filtration technologies to capture contaminants effectively.

- Airflow Requirements The filter must be compatible with the airflow needs of the dust collection system to function efficiently.

- Operating Environment The physical and chemical environment where the filter will be used can influence its performance and longevity, thus requiring careful selection of materials.

- Maintenance Considerations Opting for filters that are easy to clean and maintain can save time and reduce operational costs.

Conclusion

In conclusion, industrial dust collector cartridge filters are vital components in maintaining a safe and compliant workplace environment. Their advanced design and capabilities allow industries to effectively manage hazardous dust emissions, ensuring the health and safety of employees while protecting machinery and adhering to environmental regulations. By choosing the right filtration system and maintaining it correctly, industries can enhance operational efficiency and contribute to a cleaner planet. Investing in high-quality cartridge filters is not merely a regulatory obligation but a commitment to workplace safety and environmental responsibility.

-

The impact of different filter materials on air filter performanceNewsMay.12,2025

-

The "weight" secret of activated carbon filter: the heavier the better?NewsMay.09,2025

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

Email:

Email: