Tel:

+8618931101301

Tel:

+8618931101301

اگست . 13, 2024 01:12 Back to list

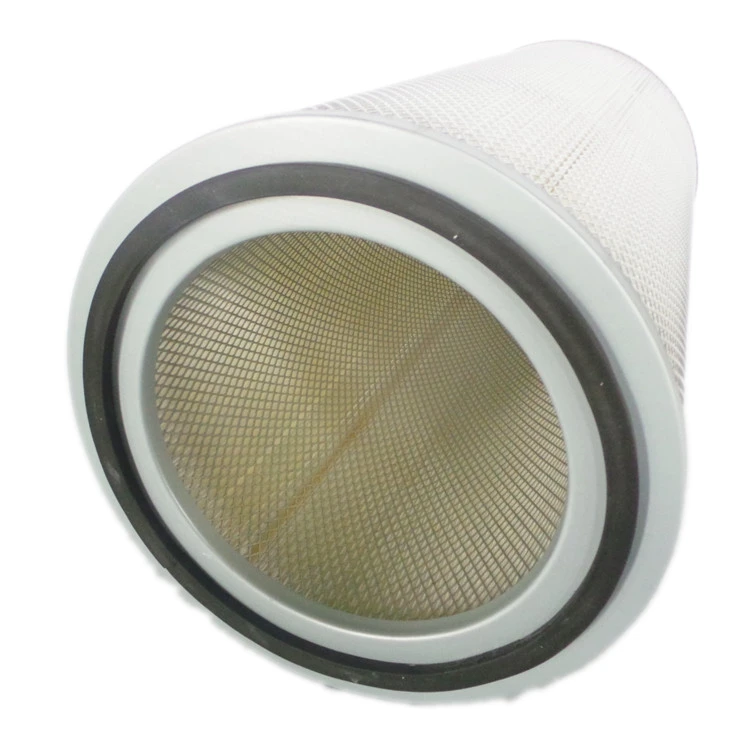

Efficient Filtration Solutions with Advanced Vacuum Filter Cartridge Technology for Optimal Performance

The Role and Importance of Vacuum Filter Cartridges

Vacuum filter cartridges play a crucial role in various industrial and environmental applications. Designed to separate solids from liquids, these cartridges utilize a vacuum system to enhance the filtration process, ensuring efficient and effective removal of unwanted substances. From water treatment facilities to food and beverage production, vacuum filter cartridges have become indispensable tools in maintaining product quality and environmental safety.

Understanding Vacuum Filtration

Vacuum filtration is a process that employs a vacuum pump to create negative pressure in a filtration vessel. This negative pressure aids in drawing the liquid through the filter medium, allowing for a faster and more efficient filtration process compared to gravity filtration. Vacuum filter cartridges are cylindrical filter elements used within this system. They are designed with a wide range of filter media, including woven fabrics, membranes, or porous materials, tailored to meet specific filtration requirements.

Applications of Vacuum Filter Cartridges

1. Water Treatment One of the most vital applications of vacuum filter cartridges is in the treatment of wastewater. Industries use these filters to remove contaminants, solids, and pollutants from water before it is discharged into the environment. By utilizing vacuum filter cartridges, treatment plants can enhance the clarity and safety of water, ensuring compliance with environmental regulations.

2. Food and Beverage Production In the food industry, maintaining hygiene and quality is essential. Vacuum filter cartridges help in the clarification of juices, removal of yeast and sediment, and filtration of oils. They ensure that the final products are not only safe for consumption but also visually appealing and consistent in quality.

vacuum filter cartridge

3. Pharmaceuticals The pharmaceutical sector relies heavily on vacuum filtration for the production of drugs and active ingredients. The use of vacuum filter cartridges allows for the precise removal of contaminants and ensures that the final product meets strict regulatory standards. This is particularly important in drugs that require sterile conditions.

4. Chemical Processing Many chemical processes generate by-products that need to be efficiently removed. Vacuum filter cartridges serve an essential role in these processes, helping to separate solids from liquids and ensuring that the desired chemical product is not tainted by impurities.

Advantages of Vacuum Filter Cartridges

The use of vacuum filter cartridges offers numerous advantages

- Efficiency The vacuum system accelerates the filtration process, significantly reducing filtration time compared to other methods. - Precision Different types of filter media can be used to achieve specific filtration goals, allowing for tailored solutions for various applications. - Cost-Effectiveness By improving the speed and effectiveness of the filtration process, businesses can reduce operational costs and increase productivity. - Versatility Vacuum filter cartridges are adaptable for various industries, allowing for broad application across diverse fields.

Conclusion

Vacuum filter cartridges are vital components in many industries, driven by their ability to efficiently separate solids from liquids. As businesses seek to improve their processes, maintain compliance with environmental regulations, and ensure product quality, the role of vacuum filtration becomes increasingly important. Investing in high-quality vacuum filter cartridges tailored to specific needs is an essential step toward achieving operational excellence and safeguarding public health and the environment. Whether in water treatment, food production, pharmaceuticals, or chemical processing, these cartridges represent a key technology that enhances productivity and effectiveness across various sectors.

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

-

Air filter survival guide in high-dust environmentsNewsApr.23,2025

Email:

Email: