Tel:

+8615930870079

Tel:

+8615930870079

اکتوبر . 12, 2024 05:32 Back to list

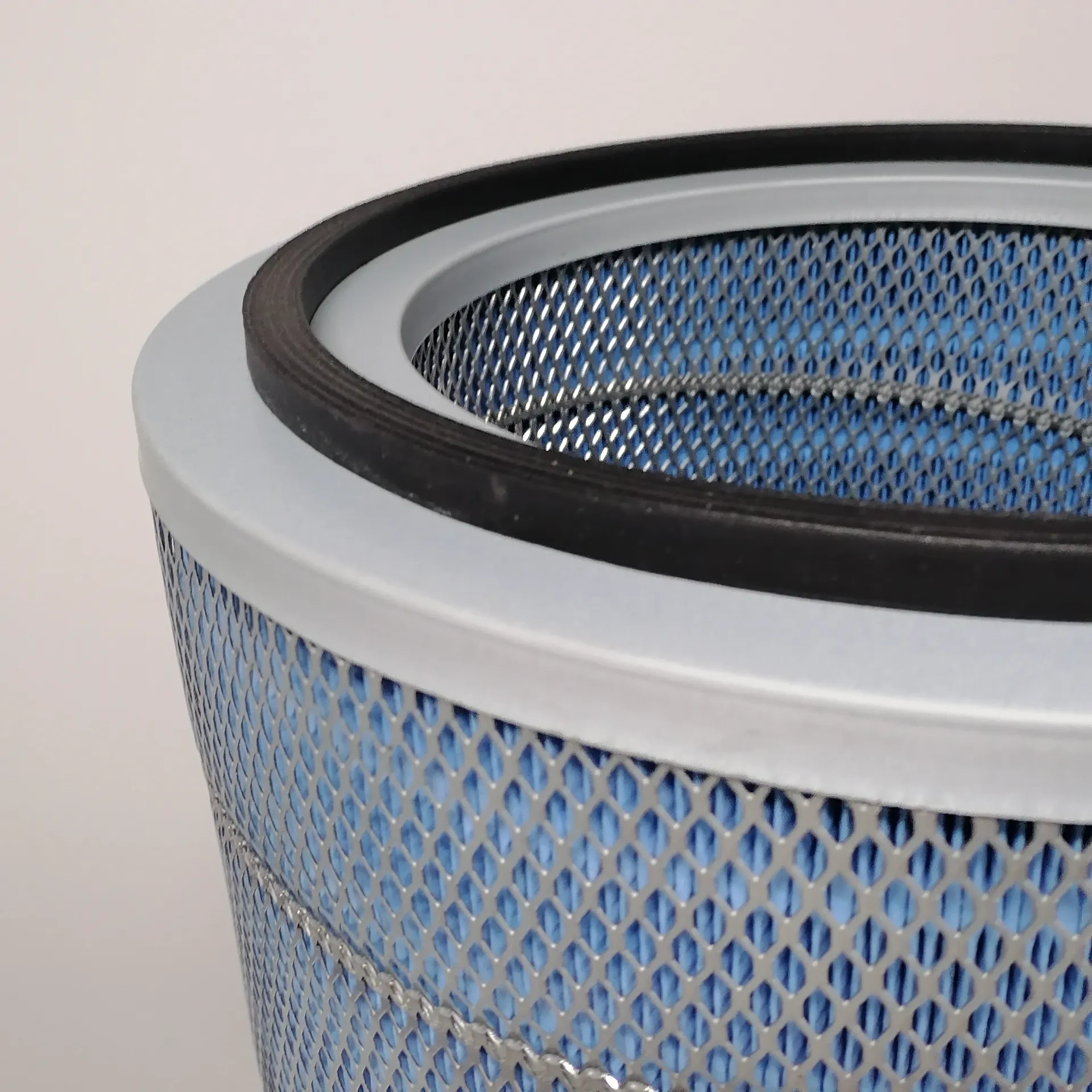

dust extractor cartridge filter

The Importance of Dust Extractor Cartridge Filters in Industrial Applications

In the contemporary industrial landscape, maintaining a safe and clean working environment is paramount. One of the most effective tools in achieving this goal is the dust extractor cartridge filter. These filters play a crucial role in air quality management, particularly in industries where dust and particulate matter are prevalent. This article delves into the significance, operation, and upkeep of dust extractor cartridge filters.

What Are Dust Extractor Cartridge Filters?

Dust extractor cartridge filters are specialized filtration systems designed to capture and eliminate airborne dust and particulates generated during various industrial processes. These filters consist of cylindrical cartridges that contain a high-efficiency filtration medium. When air is drawn through the filter, the particulate matter is trapped while the purified air is released, ensuring a clean environment for workers and machinery alike.

How Do They Work?

The functioning of a dust extractor cartridge filter revolves around a combination of mechanical and electrostatic filtration principles. As dust-laden air enters the filter, it undergoes several processes

1. Inertial Impaction Larger particles tend to collide with the filter media and get trapped due to their inertia. 2. Interception Particles that follow the airflow tend to get captured by fibers in the filter due to their proximity.

3. Diffusion Smaller particles move erratically and are more likely to collide with the filter fibers, leading to their capture.

The efficiency of these filters is often rated by their ability to capture various particle sizes, typically expressed in percentages. High-efficiency filters can capture particles as small as 0.3 microns.

Types of Dust Extractor Cartridge Filters

Dust extractor cartridge filters come in various types, each designed for specific applications

1. Pleated Cartridge Filters These filters offer a large surface area within a compact design, enhancing dust collection efficiency. 2. HEPA Filters High-Efficiency Particulate Air filters are designed to capture at least 99.97% of particles that are 0.3 microns in diameter.

3. Activated Carbon Filters These filters incorporate a material designed to absorb gaseous pollutants, making them ideal for industries where chemical fumes are released.

4. Specialty Filters Tailored for specific applications, such as capturing metal or wood dust, these filters address the unique challenges faced by diverse industries.

dust extractor cartridge filter

Benefits of Using Dust Extractor Cartridge Filters

1. Enhanced Air Quality By efficiently removing dust and particulates from the air, these filters contribute to a healthier work environment, reducing the risk of respiratory issues among workers.

2. Increased Equipment Longevity Reducing dust accumulation on machinery not only improves operational efficiency but also extends the lifespan of equipment by preventing wear and tear.

3. Regulatory Compliance Many industries are subject to strict air quality regulations. Utilizing effective dust extraction systems can aid in compliance with occupational health and safety standards.

4. Cost Efficiency Although there is an upfront investment in purchasing and installing dust extractor systems, the long-term savings in health-related costs and equipment maintenance often outweigh the initial expenses.

Maintenance and Best Practices

To ensure optimal performance, regular maintenance of dust extractor cartridge filters is essential. Following are some best practices

1. Regular Inspections Periodically check the filters for signs of wear, damage, or clogging.

2. Scheduled Cleanings Depending on the volume of dust produced, establish a routine cleaning schedule to prevent decrease in airflow and efficiency.

3. Timely Replacements Follow manufacturer guidelines for filter replacement to maintain optimal filtration performance.

4. Training Staff Educate staff on the importance of dust management and the proper use of dust extraction systems.

Conclusion

In conclusion, dust extractor cartridge filters are indispensable components of modern industrial operations. Their ability to enhance air quality, protect equipment, and promote worker health makes them a critical investment for any industry generating airborne particulates. By understanding their operation, benefits, and maintenance needs, businesses can foster a safer and more efficient working environment for all. As industries evolve, embracing advanced filtration technologies like dust extractor cartridge filters will become increasingly essential in addressing the challenges posed by dust and particulate matter.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: