Tel:

+8615930870079

Tel:

+8615930870079

ستمبر . 26, 2024 00:14 Back to list

Antistatic Filter Element for Enhanced Performance and Safety in Various Applications

The Importance and Functionality of Antistatic Filter Elements

In various industrial and technological applications, maintaining a clean and controlled environment is crucial for the efficiency and longevity of machines and processes. One critical component in achieving this goal is the antistatic filter element. Designed to mitigate the risks associated with static electricity, these filters play a vital role in ensuring the reliability and performance of filtering systems across numerous sectors.

Antistatic filter elements are specifically engineered to reduce static charge buildup on filter surfaces. Static electricity can lead to a host of problems, including dust attraction, operational inefficiencies, and even fire hazards in extreme cases. By incorporating conductive or dissipative materials, antistatic filters help prevent the accumulation of dust and particulate matter on their surfaces, ensuring consistent airflow and filtration performance.

These filter elements are essential in environments where airborne particles can compromise product quality, such as in cleanrooms, pharmaceuticals, and food processing industries. In such settings, even minor contaminations can have significant repercussions, making the role of antistatic filters paramount. They not only help to maintain air quality but also protect sensitive equipment and products from potential damage caused by static discharges.

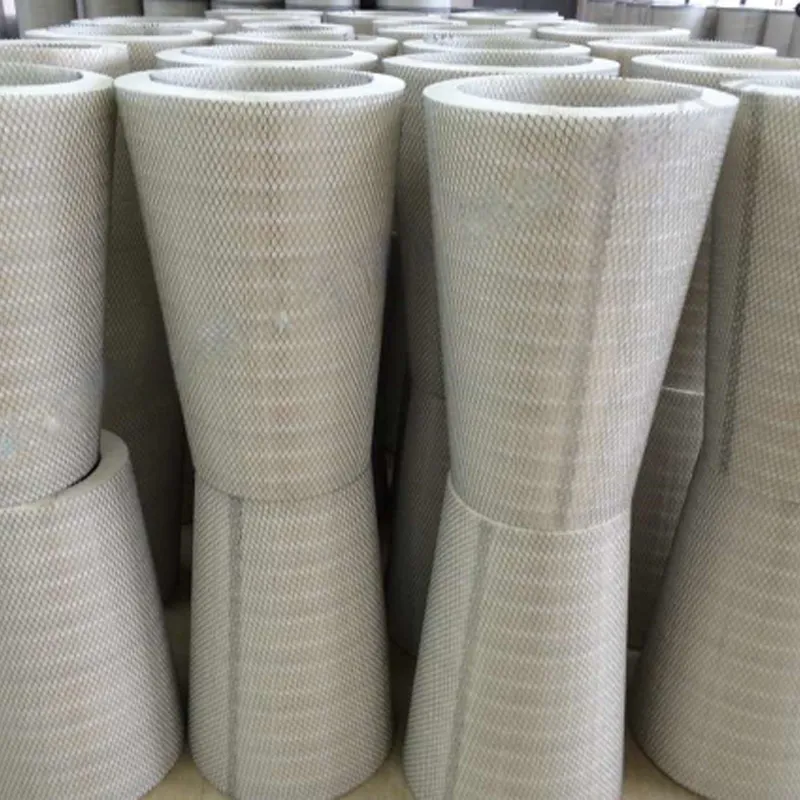

antistatic filter element

Moreover, antistatic filter elements are highly versatile and can be integrated into various types of filtration systems, including HEPA filters, electrostatic precipitators, and more

. Their adaptability makes them suitable for numerous applications, ranging from industrial machinery and HVAC systems to consumer electronics and automotive manufacturing.The performance characteristics of antistatic filter elements are further enhanced by their ability to withstand extreme operating conditions. Many of these filters are designed to endure high temperatures and humidity, thereby extending their service life and reducing maintenance costs. This durability is particularly important in industries that require continuous operation under demanding conditions, ensuring that the filters remain functional and effective over time.

In conclusion, antistatic filter elements are an essential component in maintaining a safe and efficient working environment. Their ability to suppress static electricity not only enhances filtration efficiency but also protects equipment and products from contamination and damage. As industries continue to evolve and innovate, the role of antistatic filters will remain critical, underpinning the integrity and reliability of modern filtration systems. By investing in quality antistatic filter elements, companies can ensure operational excellence and enhanced product quality.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: