Tel:

+8618931101301

Tel:

+8618931101301

พ.ย. . 28, 2024 13:47 Back to list

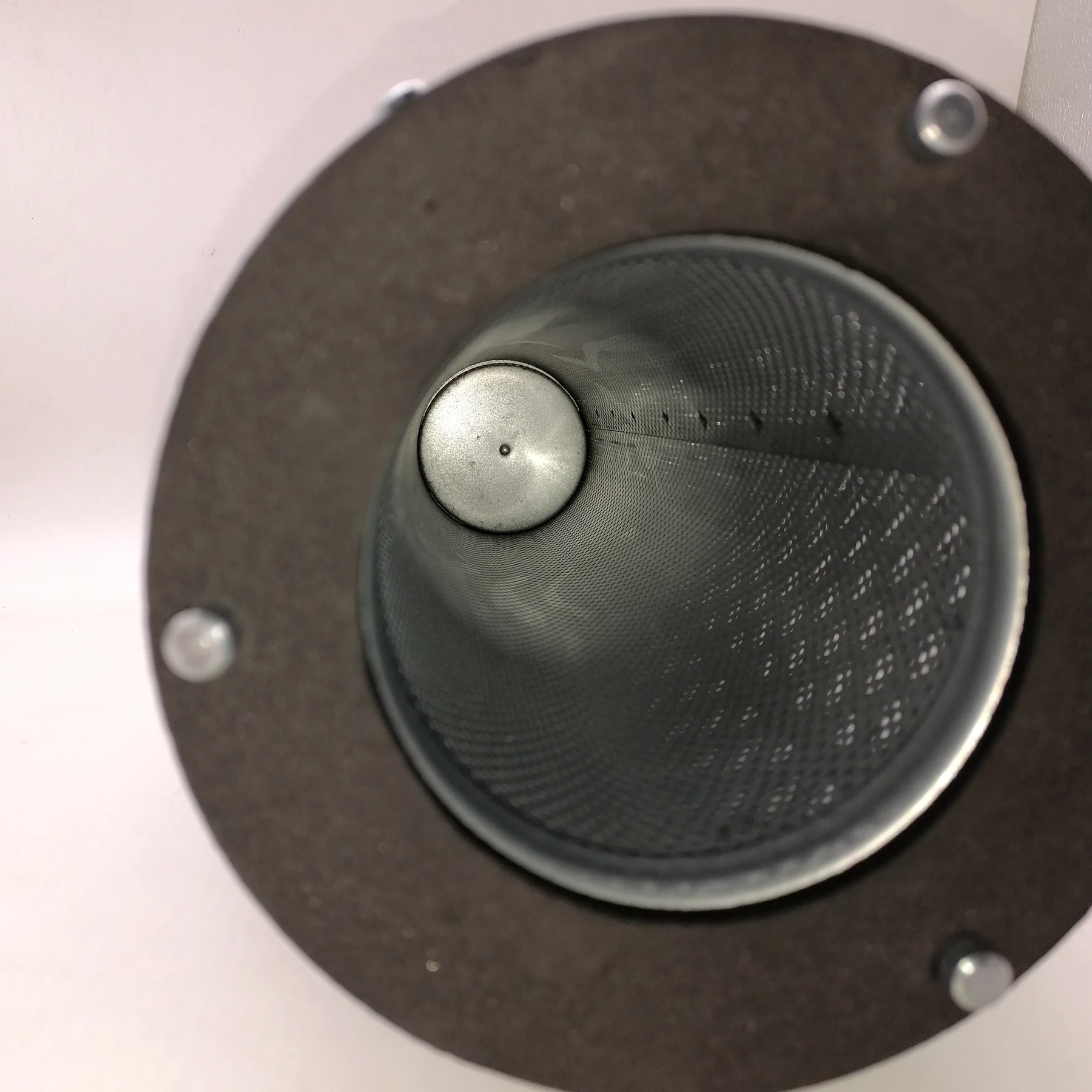

Stainless Steel Sintered Filter Cartridge for Enhanced Filtration Efficiency and Durability

Understanding SS Sintered Filter Cartridges Applications and Benefits

In various industries, the need for efficient filtration systems is paramount. Among the myriad of filtration solutions, SS (Stainless Steel) sintered filter cartridges stand out as a compelling choice due to their unique manufacturing process and superior performance characteristics. This article delves into the features, benefits, and applications of SS sintered filter cartridges, shedding light on why they are increasingly preferred in industrial filtration processes.

What are SS Sintered Filter Cartridges?

Sintered filter cartridges are porous filters made from stainless steel, produced through a process known as sintering. In this process, stainless steel powders are compacted and then heated to a point where the particles bond together without melting. This results in a solid, rigid structure with an interconnected pore network that allows for effective filtration while maintaining structural integrity under varying operating conditions.

SS sintered filter cartridges are often characterized by their excellent corrosion resistance, high mechanical strength, and the ability to withstand high temperatures, making them suitable in demanding environments where traditional filter materials may fail.

Key Characteristics

1. Durability One of the most significant advantages of SS sintered filter cartridges is their durability. Unlike polymer-based filters, which can degrade over time, stainless steel cartridges can last longer, reducing the need for frequent replacements.

2. Chemical Resistance Sintered stainless steel is resistant to most chemicals, including acids, bases, and solvents, making these cartridges ideal for a wide range of applications in industries such as chemical processing and pharmaceuticals.

3. High Filtration Efficiency The sintering process creates a filter with precise pore sizes, allowing for targeted filtration according to specific requirements. Whether it’s removing particulates in a fluid or separating phases in a mixture, SS sintered filters offer exceptional performance.

4. Cleanability These cartridges are not only robust but are also easily cleanable. They can often be backwashed or cleaned using ultrasonic methods, ensuring that they maintain their performance over time without needing to be disposed of.

ss sintered filter cartridge

5. Customization SS sintered filter cartridges can be customized in terms of size, porosity, and configuration, making them versatile for various applications.

Applications of SS Sintered Filter Cartridges

Given their numerous advantages, SS sintered filter cartridges find applications across a broad spectrum of industries

1. Chemical Industry In chemical manufacturing, these filters are employed to remove catalysts, particulates, and other impurities from process streams, thereby ensuring product quality and compliance with safety standards.

2. Pharmaceutical Industry The high purity and resistance to contamination make SS sintered filters ideal for critical applications such as drug formulation and sterility testing, where any impurities can have serious consequences.

3. Food and Beverage Sintered filter cartridges are extensively used in the food and beverage sector for processes such as wine clarification, oil filtration, and juice processing, where hygiene and safety are paramount.

4. Oil and Gas In the oil and gas industry, these filters are used for the filtration of drilling mud, separation of phases, and protecting sensitive equipment from particulates.

5. Water Treatment SS sintered filters are also employed in water purification systems, where they can effectively remove sediment and other impurities from water, ensuring clean and safe drinking water.

Conclusion

SS sintered filter cartridges provide a combination of durability, efficiency, and versatility that make them an excellent choice for industrial filtration applications. As industries increasingly seek reliable and long-lasting filtration solutions, the adoption of stainless steel sintered filters is expected to grow. Their ability to withstand harsh environments while delivering high performance aligns with the modern demands of manufacturing processes, ensuring that they remain a key player in filtration technology for years to come. Whether in chemical production, pharmaceuticals, or water treatment, SS sintered filter cartridges are sure to play a crucial role in ensuring the purity and quality of processed materials.

-

Cold knowledge of air filters: Why are some designed to be pleated?NewsJun.16,2025

-

Factory direct supply! High-precision air filter element wholesale and customizationNewsJun.12,2025

-

A complete analysis of the practical value of activated carbon filtersNewsJun.10,2025

-

Why are high iodine coconut shell activated carbon filters more durable?NewsJun.06,2025

-

Gas Turbine FilterNewsJun.06,2025

-

Filter TurbineNewsJun.06,2025

Email:

Email: