Tel:

+8615930870079

Tel:

+8615930870079

ต.ค. . 22, 2024 03:01 Back to list

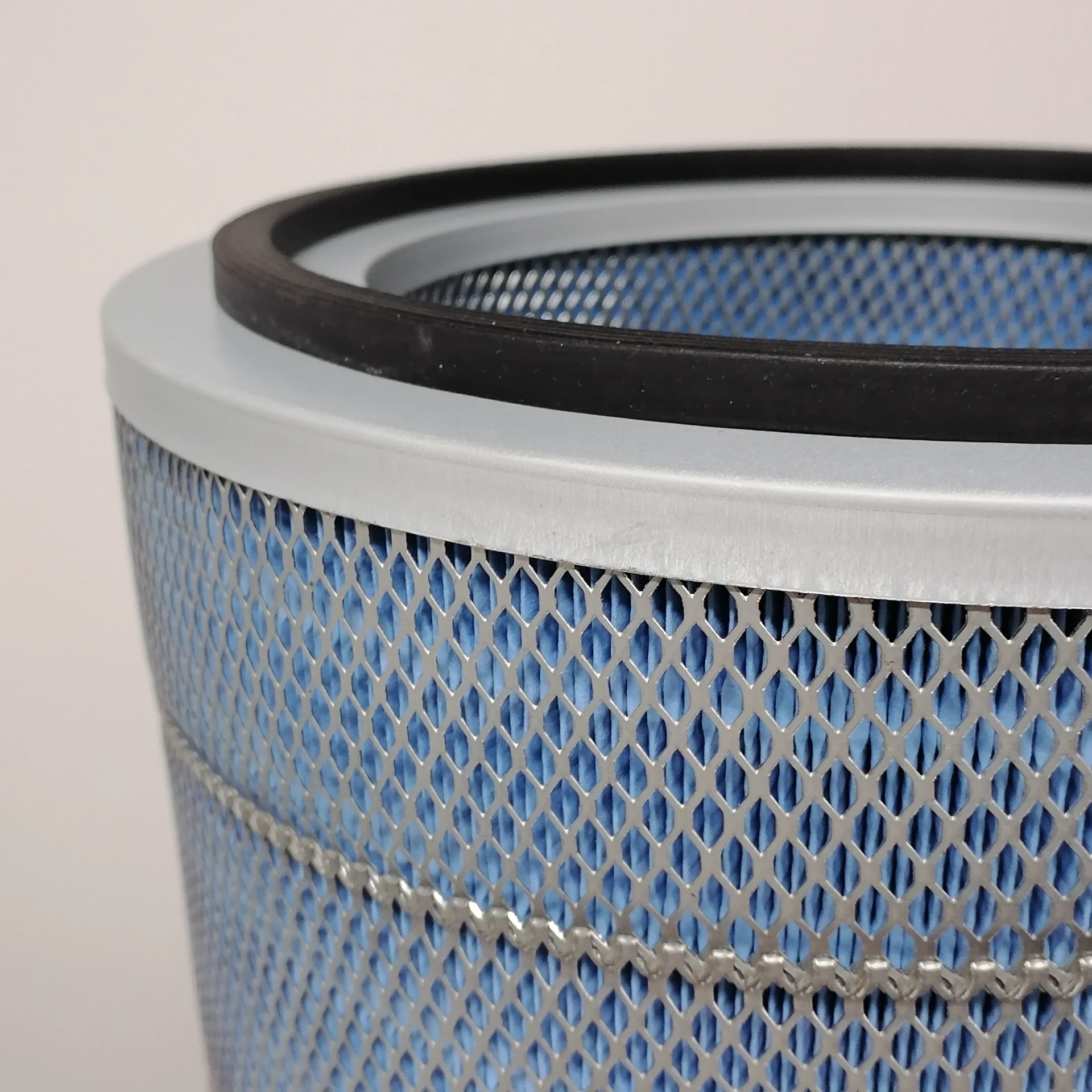

Stainless Steel Sintered Filter Cartridge for Efficient Filtration Solutions

The SS Sintered Filter Cartridge A Comprehensive Overview

In the realm of filtration technology, one of the standout innovations is the stainless steel (SS) sintered filter cartridge. This advanced filtering solution has gained significant attention across various industries due to its robustness, durability, and efficiency in removing particulates from liquids and gases. Understanding the properties, applications, and advantages of SS sintered filter cartridges can provide insights into their growing popularity in industrial processes.

What is a Sintered Filter Cartridge?

A sintered filter cartridge is a filtration device made from metallic or non-metallic materials that are fused together through a process known as sintering. In the case of stainless steel, fine particles are heated to a temperature below their melting point, allowing the particles to bond together. This process creates a porous structure that retains its shape and provides high strength. The result is a filter that can effectively trap solid particles while allowing fluids to pass through with minimal resistance.

Advantages of SS Sintered Filters

1. Durability Stainless steel sintered filters are exceptionally durable and can withstand high temperatures and pressures, making them ideal for demanding environments. Their resistance to corrosion ensures longevity, even when exposed to harsh chemicals. 2. Efficient Filtration With a pore size ranging from microns down to sub-microns, these filters are highly effective at removing fine particulates and contaminants. This precision in filtration is crucial for maintaining product quality in various applications.

3. Easy Cleaning and Reusability One of the most significant advantages of SS sintered filters is their ability to be cleaned and reused. Unlike traditional filters, which often need to be discarded after a single use, stainless steel filters can be backwashed or chemically cleaned, offering a more sustainable and cost-effective solution.

4. Customizable Properties Sintered filters can be engineered to meet specific requirements, including filtration efficiency, flow rate, and chemical compatibility. Manufacturers can tailor the pore structure and thickness to suit various applications, which enhances versatility.

ss sintered filter cartridge

Applications of SS Sintered Filter Cartridges

SS sintered filter cartridges are widely utilized across myriad industries, including

- Pharmaceuticals In drug production processes, purity is paramount. Sintered filters help maintain the integrity of the final product by eliminating contaminants during filtration stages.

- Food and Beverage In the food industry, these filters are critical for ensuring product safety and quality. They are used in processes such as brewing beer, clarifying juices, and other applications where contamination must be controlled.

- Chemical Processing Many chemical processes involve corrosive substances. SS sintered filters are capable of withstanding these harsh environments while ensuring efficient filtration of byproducts and particulates.

- Water Treatment These filters are also fundamental in water treatment applications, where they play a vital role in removing suspended solids and impurities, contributing to cleaner and safer water supplies.

Conclusion

In summary, the SS sintered filter cartridge represents an essential component in modern filtration systems. Its advantages in terms of durability, reusability, and efficient filtration make it a preferred choice for industries that prioritize quality and reliability. With ongoing advancements in material science and engineering, the future of sintered filters looks promising, potentially opening new avenues for innovative applications and improved filtration solutions. As industries continue to evolve, the demand for efficient and sustainable filtration solutions like the SS sintered filter cartridge will undoubtedly contribute to enhanced operational efficiencies and product integrity.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: