Tel:

+8615930870079

Tel:

+8615930870079

ต.ค. . 03, 2024 23:46 Back to list

High-Performance Stainless Steel Sintered Filter Cartridge for Efficient Filtration Solutions

Understanding SS Sintered Filter Cartridges A Key Component in Filtration Systems

In various industrial applications, the need for effective filtration solutions is paramount. Among the myriad of filtration technologies available, SS (Stainless Steel) sintered filter cartridges stand out as a reliable and efficient choice. These cartridges offer several advantages over traditional filter media, making them essential in processes that require the highest purity levels.

What is a Sintered Filter Cartridge?

A sintered filter cartridge is made by compressing and heating stainless steel particles until they fuse together, forming a porous structure. This process creates a robust filter medium that allows for effective particle removal while maintaining high strength and integrity. SS sintered filters can be engineered to achieve specific pore sizes, making them versatile for various applications, from food and beverage production to oil and gas filtration.

Advantages of SS Sintered Filter Cartridges

1. Durability and Longevity One of the primary benefits of SS sintered filter cartridges is their durability. Unlike conventional filter media, which may degrade or clog over time, sintered filters can withstand harsh operating conditions, including high temperatures and pressures. This durability translates into longer service life and reduced replacement costs, making them a cost-effective filtration solution.

2. High Chemical Resistance Stainless steel is known for its corrosion resistance, which is particularly important in industries that deal with aggressive chemicals or abrasive materials. SS sintered filter cartridges can be used in a wide range of applications, including those involving acids, solvents, and corrosive fluids, ensuring that the filtration process remains efficient and effective.

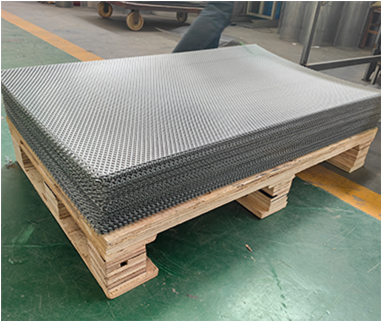

ss sintered filter cartridge

3. Ease of Cleaning and Maintenance Another significant advantage of SS sintered filter cartridges is their cleanability. Unlike paper or polymer filters that can become contaminated, stainless steel filters can be backwashed or cleaned using various methods, such as ultrasonic cleaning or chemical baths. This feature not only maintains filtration efficiency but also extends the lifespan of the cartridge.

4. Customizable Pore Sizes SS sintered filters can be designed with various pore sizes, allowing for precise filtration according to specific needs. Depending on the application requirements, these filters can effectively remove particles of different dimensions, ensuring that the end product meets stringent quality standards.

Applications of SS Sintered Filter Cartridges

The versatility of SS sintered filter cartridges makes them suitable for various industries. In the pharmaceutical industry, these filters are used to ensure that sterilized products are free from contaminants. In the food and beverage sector, they play a crucial role in maintaining product integrity and safety by removing unwanted particles. Additionally, in the oil and gas industry, they are vital for protecting machinery and ensuring the efficient operation of systems by filtering out particulates and sediments.

Conclusion

In summary, SS sintered filter cartridges represent a superior filtration solution that combines durability, versatility, and efficiency. Their ability to withstand challenging conditions, resist chemical degradation, and be cleaned for repeated use makes them an indispensable component in many industrial applications. As industries continue to prioritize quality and efficiency, the demand for advanced filtration technologies like SS sintered filters is expected to grow, further solidifying their role in modern manufacturing and processing environments. Whether for liquid or gaseous applications, investing in SS sintered filter cartridges is a proactive step toward enhancing system performance and ensuring a high-quality output.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: