Tel:

+8615930870079

Tel:

+8615930870079

ธ.ค. . 12, 2024 20:52 Back to list

ss filter cartridge

Understanding SS Filter Cartridges The Key to Efficiency and Purity

In today’s fast-paced industrial world, the demand for high-quality filtration solutions has never been more critical. One of the standout products in this domain is the stainless steel (SS) filter cartridge. These cartridges play a vital role in ensuring the purity of fluids across various applications, from pharmaceuticals to food and beverage production. This article delves into the significance, features, and advantages of SS filter cartridges, providing insight into why they are an essential component of modern filtration systems.

What is an SS Filter Cartridge?

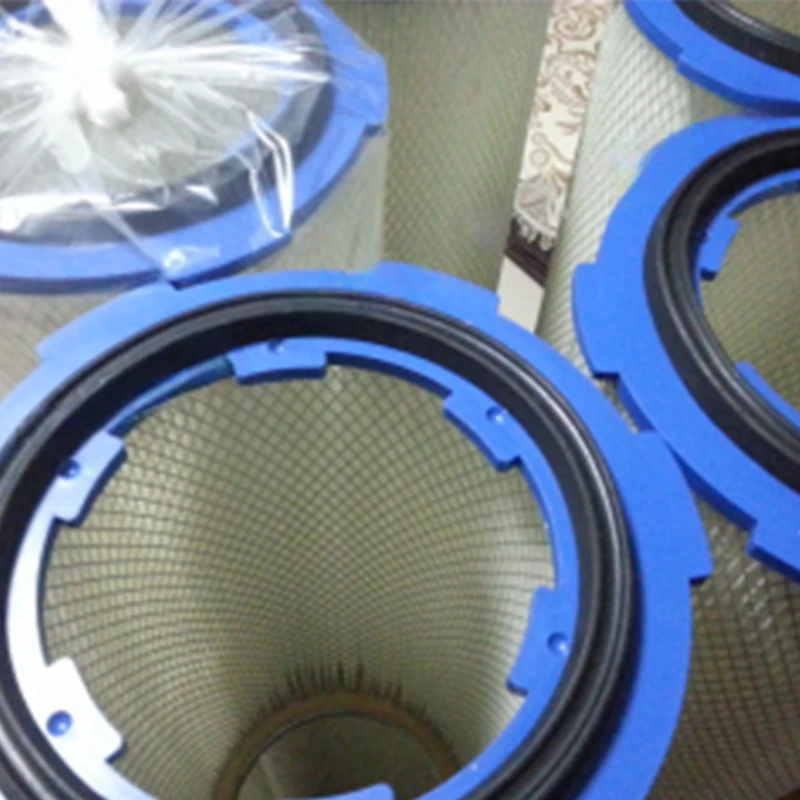

An SS filter cartridge is a cylindrical filtration device made from stainless steel, designed to remove impurities from liquids and gases. The core structure typically comprises a filter medium enclosed in a stainless steel housing, providing durability and resistance to corrosion and high temperatures. Depending on the specific needs of the application, the filter media may vary in porosity, allowing for tailored filtration solutions.

Applications of SS Filter Cartridges

SS filter cartridges are utilized in a myriad of industries, showcasing their versatility and importance. Some common applications include

1. Pharmaceutical Industry In the production of medicines, ensuring the purity of solutions is paramount. SS filter cartridges reliably remove contaminants, ensuring that products meet stringent regulatory standards.

2. Food and Beverage These cartridges are essential in maintaining the quality and safety of consumables. They effectively filter out particulates that could affect food safety and taste.

3. Chemical Processing The chemical industry often utilizes SS filter cartridges due to their durability and chemical resistance, essential for filtering aggressive substances.

ss filter cartridge

4. Water Treatment In municipal and industrial water treatment facilities, SS filter cartridges are employed to enhance water quality by removing suspended solids and other pollutants.

Advantages of SS Filter Cartridges

1. Durability and Longevity SS filter cartridges are designed to withstand harsh conditions, including high temperatures and corrosive environments. Unlike their plastic counterparts, stainless steel does not degrade over time, ensuring a long service life and reducing replacement frequency.

2. Easy to Clean and Reuse Many SS filter cartridges can be cleaned and sanitized, making them reusable and environmentally friendly. This reduces waste and the cost associated with constant replacements.

3. Superior Filtration Efficiency The pore structure of SS filter cartridges can be precisely engineered to achieve desired filtration levels, capturing particles as small as a few microns. This guarantees high filtration efficiency and the removal of microorganisms.

4. Cost-Effectiveness Although the initial investment in SS filter cartridges may be higher than other materials, their durability and reusable nature often result in lower overall costs in industrial applications. The reduction in downtime for filter changes also contributes to operational efficiency.

5. Versatile Design Options SS filter cartridges come in various designs, such as pleated, spun, or wound, allowing customization to meet specific filtration requirements. This adaptability makes them suitable for a wide range of systems and processes.

Conclusion

In conclusion, stainless steel filter cartridges are indispensable in many sectors, ensuring the purity and quality of fluids and gases while maintaining operational efficiency. Their durability, ease of cleaning, and superior filtration capabilities make them an excellent investment for industries that prioritize quality. As industries continue to evolve and face new challenges, SS filter cartridges will undoubtedly remain at the forefront of filtration technology, providing reliable and efficient solutions for a cleaner, safer world. Whether for food manufacturing or pharmaceutical production, understanding and utilizing SS filter cartridges can lead to significant improvements in product quality and compliance.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: