Tel:

+8618931101301

Tel:

+8618931101301

พ.ย. . 09, 2024 20:39 Back to list

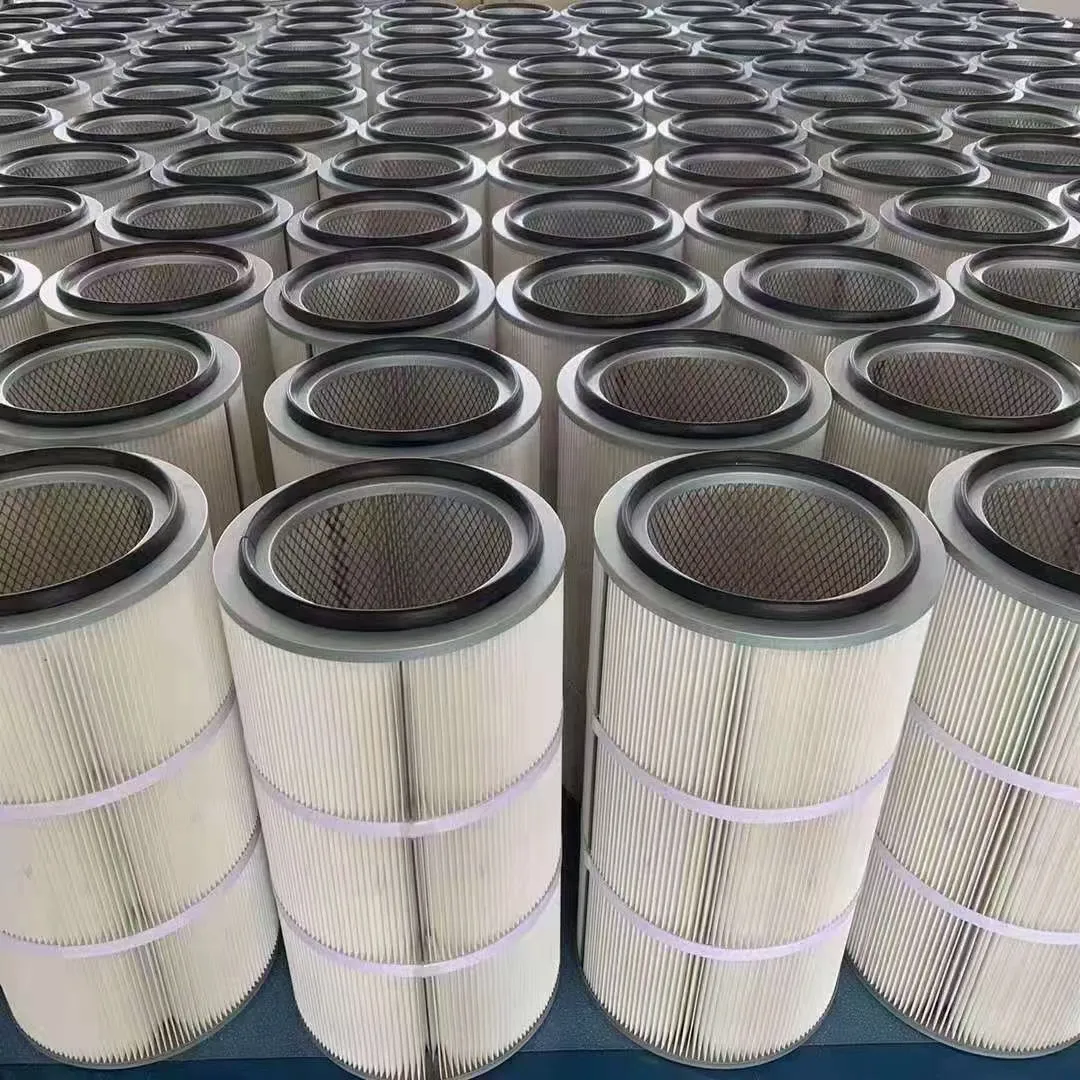

Advanced Sintered Metal Filter Cartridges for Enhanced Liquid Filtration Solutions

Understanding Sintered Metal Filter Cartridges A Comprehensive Overview

Sintered metal filter cartridges have emerged as an essential component in various industrial applications, owing to their remarkable properties, durability, and filtration efficiency. These filters are crafted from metal powders that are expertly pressed and then heated to bond the particles together, a process known as sintering. This innovative manufacturing technique allows for the creation of porous materials that exhibit high strength, corrosion resistance, and the ability to withstand extreme temperatures and pressures.

One of the defining characteristics of sintered metal filters is their unique porosity. The pore sizes can be precisely controlled during the sintering process, enabling the production of filters with specific filtration levels to meet diverse applications. This adaptability makes sintered metal filters ideal for industries such as oil and gas, water treatment, pharmaceuticals, and food processing, where contaminants must be effectively removed without compromising the integrity of the system.

Advantages of Sintered Metal Filter Cartridges

1. Durability and Longevity Unlike traditional filter media, which can degrade over time or become clogged, sintered metal filters are built to last. Their robustness allows them to endure harsh conditions, reducing the need for frequent replacements and maintenance.

2. Chemical and Heat Resistance Sintered metal materials are compatible with a wide range of chemicals and can operate under high temperatures. This resistance is crucial in applications where chemical exposure can lead to filter failure or degradation.

3. Cleanability One of the most significant advantages of sintered metal filters is that they can be cleaned and reused. Various cleaning methods, including backwashing and ultrasonic cleaning, can effectively restore their filtration capability. This feature not only reduces waste but also lowers operational costs over time.

sintered metal filter cartridge

4. High Filtration Efficiency With precise control over pore sizes, sintered metal filters achieve high levels of filtration efficiency. They can effectively capture particulate matter, including fine particles that are often challenging to filter out using traditional media, thus ensuring cleaner output.

5. Versatility Sintered metal filters can be manufactured in various shapes and sizes, accommodating different filtration needs across multiple industries. Whether in the form of cartridges, discs, or custom-designed components, their versatility enhances their applicability in specific scenarios.

Applications of Sintered Metal Filters

The industrial versatility of sintered metal filter cartridges allows them to perform effectively in various applications. In the oil and gas sector, for example, these filters are employed to remove solid impurities from fuels and lubricants, ensuring efficiency and longevity of machinery. In water treatment, sintered metal filters help remove sediments and contaminants, producing cleaner water for both industrial and municipal use.

In the pharmaceutical industry, maintaining the purity of products is crucial. Sintered metal filters are used to filter out contaminants in liquids and gases, preserving the integrity of pharmaceuticals and ensuring compliance with stringent regulations. The food industry also benefits from the application of these filters, where they play a vital role in filtering oils and beverages, ensuring quality and safety.

Conclusion

In conclusion, sintered metal filter cartridges represent a significant advancement in filtration technology, offering an array of benefits including durability, high filtration efficiency, and cleanability. Their ability to withstand harsh conditions while providing reliable performance makes them an invaluable asset in multiple industries. As industries continue to seek more efficient and sustainable solutions, the role of sintered metal filters will undoubtedly grow, leading to improved processes and enhanced product quality across the board. Thus, understanding and implementing these innovative filters can lead to considerable advancements in industrial operations, driving efficiency and sustainability in an increasingly competitive landscape.

-

Why is coconut shell activated carbon the preferred material for high-end filter elements?NewsMay.08,2025

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

Email:

Email: