Tel:

+8615930870079

Tel:

+8615930870079

ธ.ค. . 13, 2024 01:36 Back to list

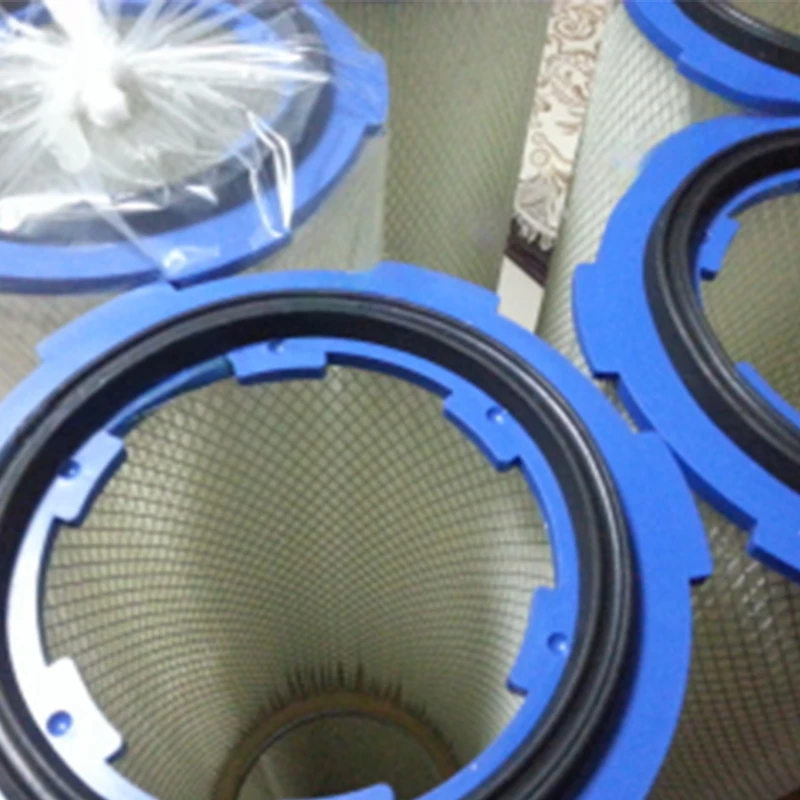

pleated filter cartridge dust collector

The Role of Pleated Filter Cartridge Dust Collectors in Modern Industrial Applications

In the highly regulated landscape of industrial operations, the need for effective dust collection systems cannot be overstated. Among the various solutions available, pleated filter cartridge dust collectors are gaining traction due to their superior efficiency, compact design, and environmental benefits. This article will explore the fundamental aspects of pleated filter cartridges, their advantages over traditional systems, and their applications across diverse industries.

Understanding Pleated Filter Cartridge Technology

Pleated filter cartridges are designed to enhance the surface area available for filtration without increasing the physical size of the filter itself. This is achieved by folding the filter media into pleats, allowing for a greater amount of material to be packed into a smaller volume. The pleating not only improves efficiency but also extends the life of the filter, which is a critical factor in cost-effectiveness and operational uptime.

Typically made from materials like polyester, polypropylene, or cellulose, the filter media is chosen based on the particulate size and type, as well as the specific requirements of the industry in which it is used. The pleating process maximizes the filtering surface—resulting in better airflow, lower pressure drops, and reduced energy consumption for the dust collection system.

Advantages of Pleated Filter Cartridge Dust Collectors

1. Efficiency One of the primary benefits of pleated filters is their high filtration efficiency. These filters can capture particles as small as 0.5 microns, making them suitable for applications that require stringent air quality standards. Their structure allows for minimal airflow resistance, which also translates into energy savings.

2. Longer Service Life The design of pleated filters provides a larger surface area, which translates to longer filter life. Fewer filter changes not only reduce maintenance costs but also minimize downtime in manufacturing processes.

3. Compact Design Pleated filter cartridges are more compact compared to traditional bag filters. This is particularly advantageous in facilities where space is at a premium. Their smaller footprint allows for easier integration into existing systems, streamlining installation and management.

4. Easy Maintenance Many pleated filter systems are designed for easy accessibility, allowing for quick changes when necessary. This ease of maintenance contributes to operational efficiency and ensures that dust collection remains a low-overhead process.

pleated filter cartridge dust collector

5. Environmental Compliance Increasingly strict environmental regulations mean that industries must invest in effective dust collection systems that minimize emissions. Pleated filter cartridge dust collectors help meet compliance standards by ensuring that harmful particulates are effectively captured and managed.

Applications Across Various Industries

Pleated filter cartridge dust collectors are widely applicable across a range of industries.

- Manufacturing In manufacturing environments, these dust collectors are essential for capturing debris and particulate from processes such as machining, sanding, and grinding. They help maintain worker health and safety while supporting a dust-free workspace.

- Pharmaceuticals The pharmaceutical industry requires extremely clean environments to avoid contamination. Pleated filters play a crucial role in ensuring optimal air quality while adhering to strict regulatory standards.

- Food Processing In this sector, maintaining hygiene and preventing the contamination of products is vital. Pleated dust collection systems help ensure that dust and allergens are effectively managed.

- Woodworking The woodworking industry generates high volumes of sawdust and wood particulates, making efficient dust collection essential. Pleated filters efficiently deal with these materials while improving the working environment.

Conclusion

As industries continue to face growing challenges related to air quality and environmental regulations, pleated filter cartridge dust collectors stand out as a highly effective solution. Their efficiency, compact design, and long service life make them an invaluable asset in various sectors from manufacturing to pharmaceuticals. By implementing these advanced filtering technologies, companies can not only comply with regulations but also promote a healthier and more productive workplace. The transition towards more sustainable and efficient dust collection practices is not merely a choice; it is a necessity for modern industrial operations aiming to thrive in an ever-changing landscape.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: