Tel:

+8615930870079

Tel:

+8615930870079

ก.ย. . 22, 2024 23:29 Back to list

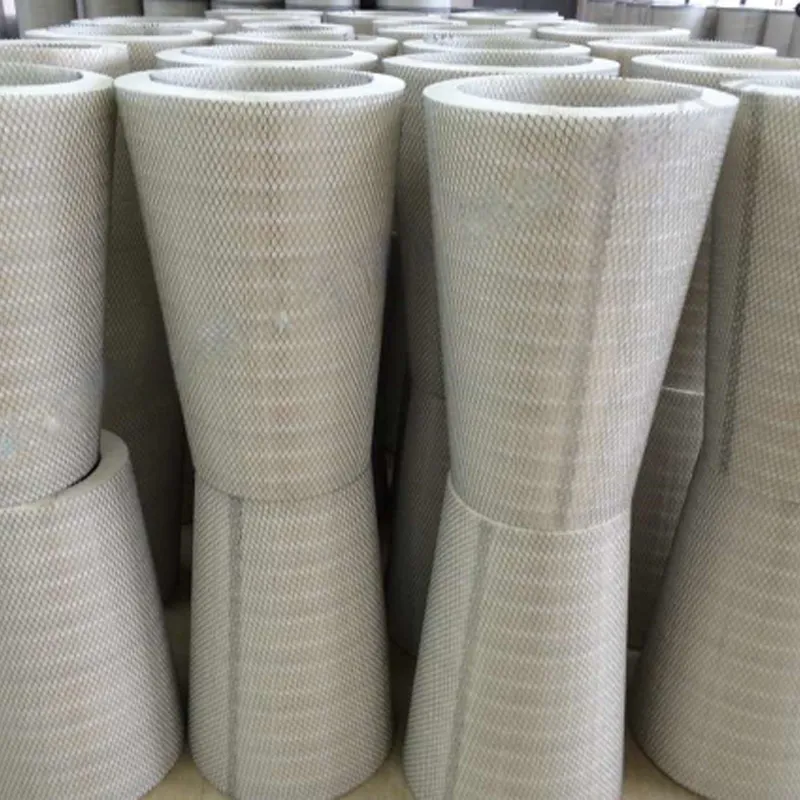

industrial air filter cartridges

The Importance of Industrial Air Filter Cartridges

In today's industrial landscape, maintaining air quality is critical for both environmental compliance and the health of workers. Industrial air filter cartridges play a vital role in this process, serving as the first line of defense against airborne pollutants, particulates, and contaminants. In this article, we will explore the significance of these cartridges, their types, applications, and best practices for choosing and maintaining them.

Understanding Industrial Air Filter Cartridges

Air filter cartridges are designed to remove harmful substances from the air in various industrial settings. They consist of porous materials, often made from fibrous materials such as fiberglass or synthetic media, that capture particulate matter and gaseous pollutants. Depending on the application, these cartridges can come in various sizes and specifications, tailored to meet specific filtration needs.

Types of Industrial Air Filter Cartridges

1. HEPA Filters High-Efficiency Particulate Air (HEPA) filters are known for their ability to capture 99.97% of particles as small as 0.3 microns. They are essential in environments requiring stringent air quality standards, such as pharmaceutical manufacturing and food processing.

2. Activated Carbon Filters These filters use activated carbon to absorb volatile organic compounds (VOCs) and odors. They are particularly useful in industries that produce strong smells or harmful gases, ensuring cleaner air release into the environment.

3. Pre-filters Often the first line of defense, pre-filters capture larger particles and extend the life of primary filters. They help reduce the overall load on more expensive filtration systems, making them cost-effective.

industrial air filter cartridges

4. Bag Filters Used for larger dust particles, bag filters offer high dust-holding capacity and can be cleaned and reused. These are common in woodworking and metal fabrication industries.

Applications of Air Filter Cartridges

Air filter cartridges are widely used across various sectors, including manufacturing, automotive, pharmaceuticals, food and beverage, and chemical processing. Each industry has distinct requirements for air quality, making it crucial to select the right type of filter cartridge for the job. For instance, in the semiconductor industry, ultra-clean air is critical, necessitating high-efficiency filtration solutions.

Best Practices for Choosing and Maintaining Air Filter Cartridges

Choosing the right air filter cartridge involves understanding the specific requirements of your application, including particle size, flow rate, and regulatory standards. It’s also important to consider the lifespan and efficiency of the cartridge to optimize replacement schedules and minimize downtime.

Regular maintenance is essential for ensuring the effectiveness of air filter cartridges. Monitoring pressure drop across filters can indicate when they need replacement, while keeping the surrounding area clean can prolong their lifespan. Additionally, training staff on proper handling and installation can prevent damage and ensure optimal performance.

Conclusion

In summary, industrial air filter cartridges are crucial components for ensuring clean and safe air in various industrial environments. With different types available and specific applications to suit, it’s important to select the right cartridge to address the unique challenges of your industry. By prioritizing maintenance and best practices, organizations can improve air quality, compliance, and overall productivity.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: