Tel:

+8615930870079

Tel:

+8615930870079

ธ.ค. . 16, 2024 03:10 Back to list

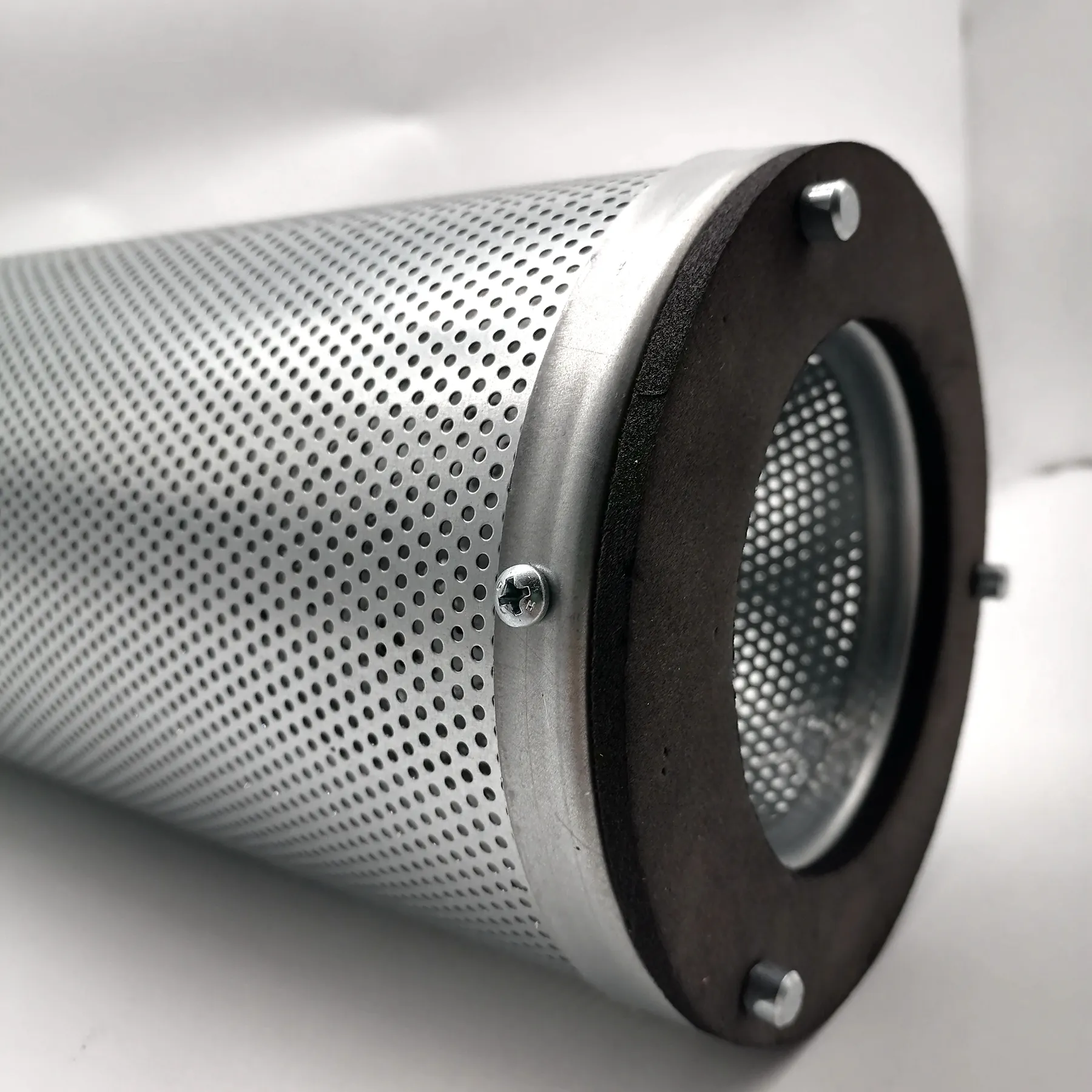

gas turbine inlet filter

The Importance of Gas Turbine Inlet Filters

Gas turbines are a crucial component in many power generation, aviation, and industrial applications. They offer significant advantages in efficiency and performance; however, one aspect that is often overlooked in their operation is the importance of inlet air filters. These filters play a vital role in ensuring the longevity and efficiency of gas turbines by protecting them from contaminants present in the atmosphere.

Understanding Gas Turbine Operation

At its core, a gas turbine operates by drawing in air, compressing it, mixing it with fuel, and igniting the mixture to produce high-velocity exhaust gases. These gases drive a turbine that generates power. The inlet air, therefore, is a primary input for the turbine's operation. Any impurities—like dust, sand, salt, or other particulates—present in the air can negatively impact the performance of the turbine.

Role of Inlet Filters

Inlet filters serve as the first line of defense against air pollutants. Their primary function is to remove particulate matter from the incoming air before it enters the turbine. This filtration process is critical for several reasons

1. Protection Against Damage Contaminants can cause erosion and wear on turbine blades and other components. Sand particles, for example, can lead to significant damage due to their abrasive nature. By filtering out these particles, inlet filters help extend the life of the turbine.

2. Efficiency Maintenance A clean air supply is essential for maintaining optimal turbine efficiency. When particles accumulate on turbine blades, they can form a layer that disrupts airflow, leading to reduced efficiency and increased fuel consumption. Proper filtration ensures that the turbine operates at its designed efficiency.

3. Operational Reliability Turbines are expected to operate reliably under various conditions. Inlet filters help maintain consistent performance levels by preventing the introduction of contaminants that could lead to unexpected failures or downtimes.

4. Environmental Compliance In some regions, regulations stipulate that air quality standards must be maintained. High-quality inlet filters can assist in meeting these regulatory requirements by reducing emissions associated with poor air quality.

Types of Inlet Filters

gas turbine inlet filter

Gas turbine inlet filters can be categorized into several types, each designed for specific applications and environments

- Panel Filters Commonly used for general air quality applications, panel filters use a layered media to capture particles. They are often installed in commercial and industrial settings.

- Bag Filters Ideal for environments with high levels of airborne particulates, bag filters provide a larger surface area for filtration, which allows for higher dirt-holding capacity and longer service life.

- Centrifugal Filters These filters utilize centrifugal force to separate dust and particulates from the air stream. They are effective in heavy-contamination scenarios and are designed to handle high volumes of airflow.

- Pre-filters Often used in conjunction with other filter types, pre-filters capture larger debris before it reaches the primary filtration stage, thus prolonging filter life and improving efficiency.

Maintenance and Best Practices

To ensure that inlet filters perform effectively, regular maintenance is essential. This includes routine inspections and replacements based on the manufacturer's recommendations and real-time monitoring of turbine performance. Implementing a predictive maintenance strategy using sensors can also help in optimizing filter changes and reducing operational costs.

Additionally, facilities should choose the appropriate filter media based on the environmental conditions and the specific operational needs of the gas turbine. Effective training of personnel responsible for the maintenance of these systems will further enhance the reliability and longevity of gas turbines.

Conclusion

In summary, gas turbine inlet filters are critical components that safeguard the performance and reliability of gas turbines. By maintaining a clean air supply, these filters prevent damage, enhance efficiency, and promote operational longevity. As industries continue to rely more heavily on gas turbines for power generation and various applications, the importance of effective inlet filtration will only grow. Ensuring the right filters are in place, along with proper maintenance practices, is essential for optimal turbine performance.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: