Tel:

+8615930870079

Tel:

+8615930870079

ต.ค. . 18, 2024 20:08 Back to list

Enhancing Performance of Gas Turbine Air Intake Filters for Optimal Efficiency

Gas Turbine Air Intake Filter Essential for Optimal Performance

In the realm of gas turbine technology, the efficiency and reliability of power generation heavily depend on the quality of the air entering the turbine. The air intake filter is a critical component that ensures the cleanliness of the airflow, ultimately affecting the performance and longevity of gas turbines. This article explores the significance of gas turbine air intake filters, their types, and their maintenance.

Importance of Air Intake Filters

Gas turbines operate on the principle of combustion, which requires a precise mixture of air and fuel. Clean air is essential for optimal combustion; any contaminants—such as dust, dirt, and particulate matter—can significantly impact the turbine's performance. Contaminated air can lead to several issues, including

1. Reduced Efficiency Dirty filters can restrict airflow, causing the turbine to work harder and consume more fuel to maintain output levels. This not only increases operational costs but also reduces overall efficiency.

2. Increased Wear and Tear Contaminants can erode components within the turbine, leading to increased maintenance costs and potential operational failures. Over time, this wear can result in unplanned outages and expensive repairs.

3. Emissions Control Stricter environmental regulations necessitate the need for cleaner emissions from gas turbines. A well-functioning air intake filter ensures that the combustion process is efficient, leading to lower emissions and compliance with environmental standards.

Types of Air Intake Filters

Gas turbine air intake filters come in various types, each suited for different operational environments and requirements

. The most common types include1. Panel Filters These are the most widely used type of air filter in gas turbines. They consist of a pleated media that captures larger particles and dust. Panel filters are typically made from synthetic or fiberglass materials, providing excellent filtration efficiency.

2. Bag Filters Bag filters have a larger surface area compared to panel filters, allowing for higher airflow and dust-holding capacity. They are suitable for applications requiring extended service intervals and are often used in environments with high dust concentrations.

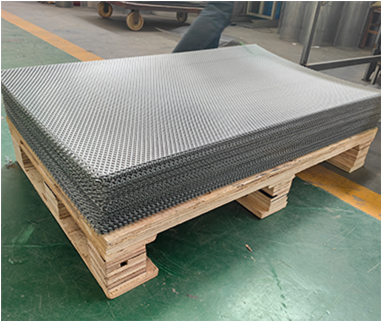

gas turbine air intake filter

3. Pre-filters These are used in conjunction with primary filters and serve to capture larger particles before they reach the main air filter. By removing larger debris, pre-filters extend the life of the primary filters and reduce maintenance frequency.

4. Electrostatic Filters Utilizing an electrostatic charge, these filters attract and capture smaller particles that standard filters may miss. They are effective in environments where high levels of fine particulate matter are present.

Maintenance Practices

Proper maintenance of air intake filters is vital for ensuring their effectiveness and prolonging the life of gas turbines. Here are some best practices

1. Regular Inspection Routine inspections should be conducted to assess the condition of the filters. This includes checking for visible dirt accumulation and ensuring that there are no tears or defects in the media.

2. Scheduled Replacements Filters should be replaced based on predetermined schedules or pressure drop measurements. Relying solely on time intervals can lead to unnecessary replacements or, conversely, to using filters beyond their effective life.

3. Cleaning Some filters, particularly those made from synthetic materials, can be cleaned and reused. It is imperative to follow the manufacturer's guidelines to avoid damaging the filter media during cleaning.

4. Monitoring Air Quality Keeping track of the air quality in the vicinity of the gas turbine can help in predicting filter life. Areas with high pollution levels may necessitate more frequent maintenance.

Conclusion

The air intake filter is a fundamental component of gas turbine systems, playing a crucial role in ensuring optimal operation and longevity. With the right type of filter and diligent maintenance practices, operators can enhance the performance of their gas turbines, reduce operational costs, and minimize environmental impact. Adequate attention to air intake filtration not only ensures efficient energy production but also contributes to sustainable practices in the energy sector. As the demand for cleaner and more efficient energy sources continues to grow, the importance of gas turbine air intake filters will remain paramount in the ongoing evolution of power generation technologies.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: