Tel:

+8615930870079

Tel:

+8615930870079

ธ.ค. . 11, 2024 04:53 Back to list

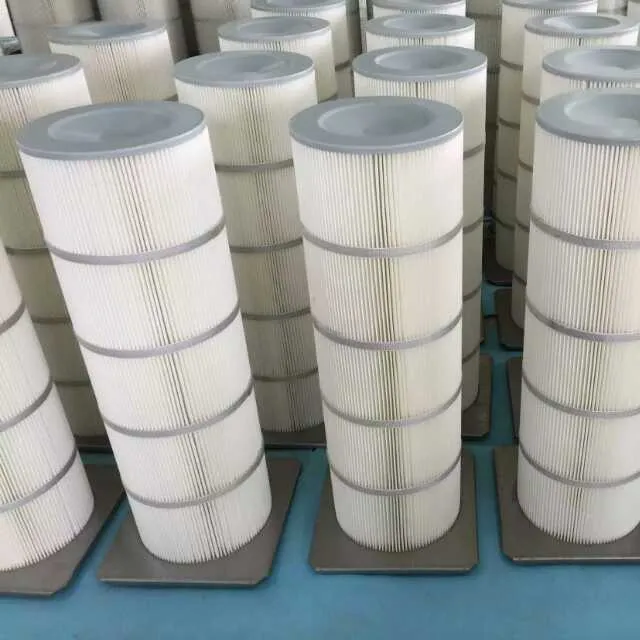

Efficient Dust Collection with Advanced Filter Cartridge Systems for Clean Environments

Understanding Filter Cartridges in Dust Collectors A Key Component for Industrial Cleanliness

In industrial environments, the management of dust and particulate matter is crucial. Dust collectors play an essential role in maintaining air quality and ensuring compliance with health and safety regulations. At the heart of many dust collection systems are filter cartridges, which are vital in capturing airborne dust and preventing it from circulating back into the environment. This article explores the importance, functionality, and maintenance of filter cartridges in dust collectors, as well as innovations in filtration technology.

What are Filter Cartridges?

Filter cartridges are cylindrical filter elements that are specifically designed to capture dust and other airborne particles. Unlike traditional bag filters, cartridge filters offer a higher filtration efficiency and a smaller footprint, making them an ideal choice for various industrial applications. These cartridges are typically made from materials such as polyester, cellulose, or fiberglass, which provide different levels of filtration performance and durability depending on the requirements of the application.

The Importance of Filter Cartridges

The primary function of filter cartridges in dust collectors is to remove harmful particles from the air. This is crucial not just for compliance with regulatory standards but also for protecting workers' health. Prolonged exposure to dust can lead to respiratory diseases, including pneumoconiosis and other chronic conditions. By effectively filtering airborne particulates, these cartridges help to create a safer and more comfortable working environment.

Another significant advantage of filter cartridges is their ability to improve operational efficiency. When dust collectors are equipped with high-quality cartridges, they can maintain lower pressure drops, leading to reduced energy consumption. In contrast, clogged or inefficient filters can cause the system to work harder, leading to higher operational costs and potential equipment failures.

Functionality of Filter Cartridges

Filter cartridges operate through the basic principles of filtration, capturing dust particles as air passes through. The design of these cartridges allows for a large surface area, which increases the amount of dust that can be collected without significantly hindering airflow.

filter cartridge dust collector

Most filter cartridges use a pleated design, which not only maximizes the filtering surface but also enhances the cartridge's overall strength. This design ensures that the cartridges can withstand the challenging conditions often found in industrial environments, including high humidity, temperature fluctuations, and exposure to various chemicals.

Maintenance and Replacement

Regular maintenance of filter cartridges is crucial to ensure their effective functioning. Over time, cartridges accumulate dust, leading to reduced airflow and increased resistance. It's essential to monitor the pressure drop across the cartridges, which indicates when they need cleaning or replacement. Many dust collection systems incorporate automatic cleaning mechanisms, such as pulse jet systems, which periodically blow compressed air through the cartridges to dislodge trapped dust.

Depending on the application and the type of dust being collected, filter cartridges may need to be replaced every few months to several years. Factors such as dust load, moisture levels, and the operating environment play significant roles in determining filter lifespan. Therefore, it’s critical to consult with manufacturers’ guidelines and conduct regular inspections to maintain optimal performance.

Innovations in Filtration Technology

Recent advancements in filtration technology have led to the development of more efficient and durable filter cartridges. New materials and coatings enhance dust release characteristics, improve particle capture efficiency, and increase service life. Additionally, smart dust collection systems utilize sensors and monitoring technology to provide real-time data on filter performance, enabling predictive maintenance and reducing unexpected downtime.

Conclusion

Filter cartridges are an essential component of dust collectors, playing a critical role in maintaining air quality and ensuring worker safety in industrial settings. Understanding the importance, functionality, and maintenance of these cartridges allows businesses to optimize their dust collection systems, ultimately leading to improved operational efficiency and compliance with health regulations. As technology continues to evolve, adopting innovative filtration solutions will be key to enhancing industrial air quality management.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: