Tel:

+8618931101301

Tel:

+8618931101301

พ.ย. . 06, 2024 08:24 Back to list

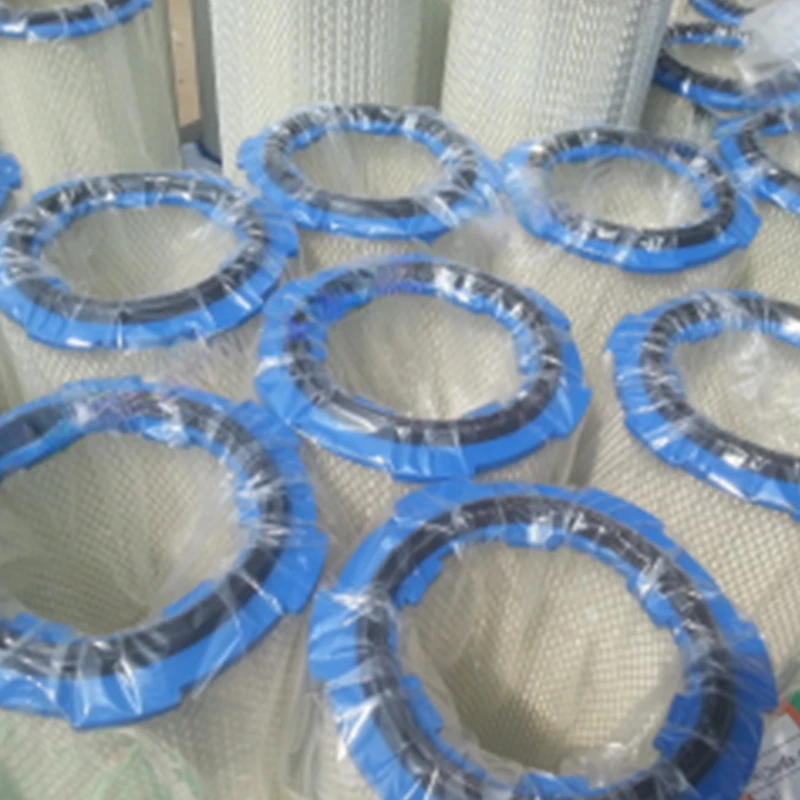

Effective Air Filter Cartridge Solutions for Dust Collection Systems

The Importance of Dust Collector Air Filter Cartridges

In industries that deal with heavy machinery, manufacturing processes, or construction, managing airborne dust is crucial for maintaining a safe and healthy work environment. Dust collector air filter cartridges play an essential role in this process, ensuring that particulates are effectively removed from the air before it is recirculated into the workspace or released into the environment. This article delves into the significance, functionality, and maintenance of dust collector air filter cartridges.

Understanding Dust Collector Systems

Dust collector systems are engineered to capture and filter out harmful dust particles created during various industrial processes. These systems are vital for compliance with environmental regulations and occupational safety standards. Dust particles can originate from many sources, including cutting, grinding, sanding, and other manufacturing processes. Without effective dust management, these particles can lead to respiratory problems in workers and can also cause damage to equipment and products.

At the heart of a dust collector system is the air filter cartridge

. These cartridges are designed to capture particles as small as a few microns, providing clean air and ensuring that facilities operate smoothly and within regulatory limits.Functionality of Air Filter Cartridges

Air filter cartridges are composed of a filtration material that traps dust and particulates. They come in various designs and materials, often using pleated filters to increase the surface area for enhanced filtration efficiency. The pleated design allows for more air to pass through while capturing a higher volume of dust.

dust collector air filter cartridge

When air passes through the cartridge, particles adhere to the filter media. As the air continues to flow, larger and heavier particles are captured, while lighter particles may require additional pre-filtration or specialized media to optimize capture efficiency. The effectiveness of a cartridge is measured by its efficiency rating, indicating the percentage of particulates it can remove from the air.

Moreover, modern cartridges are increasingly being designed to handle various airflows and dust types, improving their versatility across different applications. Features such as static charge enhancement can improve their ability to attract and retain particles, further enhancing their efficiency.

Maintenance and Replacement

The longevity and effectiveness of dust collector air filter cartridges depend on regular maintenance and timely replacement. Dust buildup reduces airflow and can lead to system inefficiencies, increased energy consumption, or even damage to the collector. Hence, monitoring pressure drops across the filters is essential; significant changes may indicate that the filters are clogged and need replacement.

Regularly scheduled maintenance should involve inspecting, cleaning, or replacing cartridges based on the manufacturer’s guidelines and the specific operational environment. Some cartridges are designed to be cleaned and reused, while others must be replaced after reaching their saturation point. Ensuring that filters are maintained can lead not only to operational improvements but also to cost savings over time.

Conclusion

Dust collector air filter cartridges are an indispensable component of industrial dust management systems. They not only protect workers' health and safety but also contribute to the overall efficiency of industrial processes. By investing in high-quality cartridges and adhering to a rigorous maintenance schedule, industries can ensure safe and clean air, promoting a healthier work environment and achieving compliance with regulatory standards. The importance of proactive dust management cannot be overstated, and air filter cartridges are at the forefront of this essential function.

-

5 maintenance tips to extend the life of dust filter elementsNewsMay.07,2025

-

Why does the air filter affect the power of the car?NewsMay.06,2025

-

When should the dust filter be replaced?NewsApr.30,2025

-

How to choose a special dust filter?NewsApr.29,2025

-

Industrial air filters: How to deal with high dust environments?NewsApr.28,2025

-

From coconut shell to coal: performance differences of activated carbon filter elementsNewsApr.24,2025

Email:

Email: