ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

ม.ค. . 26, 2025 07:47 Back to list

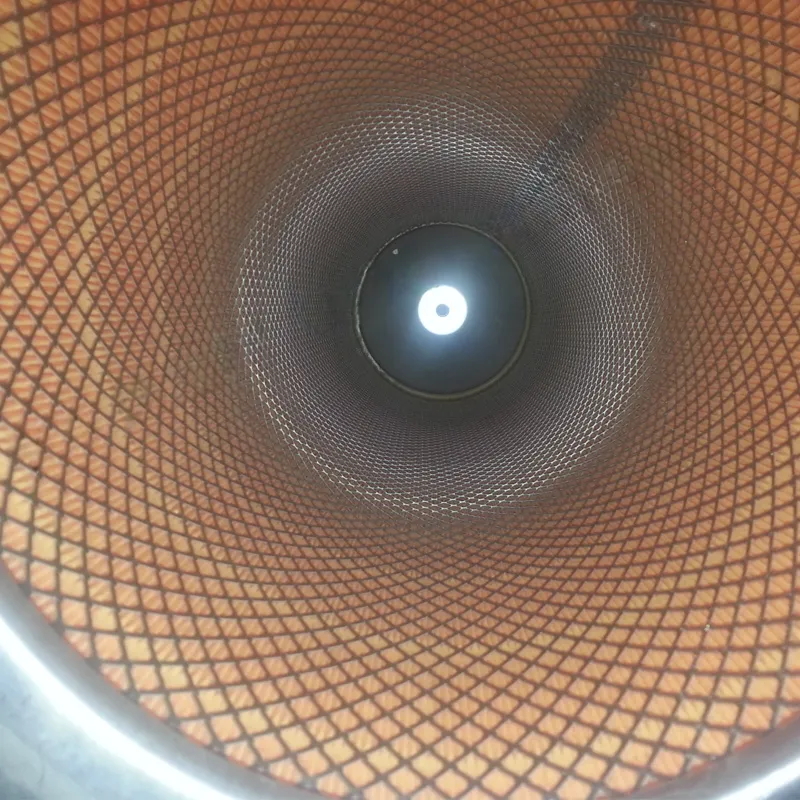

Custom-Made High Grade fine cartridge filter for dust extractor

In industrial environments, the dust collector air filter cartridge emerges as a critical component, safeguarding air quality and ensuring the longevity of machinery. Understanding its unique design, functionality, and maintenance can significantly impact the efficiency and safety of a workplace.

Trustworthiness in the field of dust collector air filter cartridges is best demonstrated through real-world applications and user testimonials. Businesses across sectors, from woodworking to pharmaceuticals, have seen marked improvements in air quality and equipment performance after upgrading to high-efficiency cartridges. For instance, a renowned furniture manufacturer reported a 30% increase in air quality after replacing their outdated filtration system with modern cartridges, which in turn reduced employee sick days and boosted productivity. Maintenance of dust collector air filter cartridges is paramount to ensure their effectiveness and longevity. Regular inspections for physical wear and tear, coupled with a periodic cleaning schedule, can greatly extend the filter's life. Implementing a pulse-jet cleaning system can automate this process, using compressed air to blow the accumulated dust off the filter surface, thus maintaining airflow and minimizing downtime. For those investing in dust collector air filter cartridges, consideration should be given to the total cost of ownership. While high-efficiency cartridges may have a higher upfront cost, their extended lifespan and reduced energy consumption often result in lower long-term expenses. Additionally, specialized filters designed for specific contaminants can prevent secondary issues, such as machine corrosion or product contamination, thereby safeguarding expensive machinery and enhancing production quality. In conclusion, a strategic approach to selecting and maintaining dust collector air filter cartridges not only improves air quality and compliance with health standards but also optimizes operational efficiency and cost management. By harnessing the latest filtration technologies and adhering to authoritative standards, industries can transform this fundamental component into a pivotal asset for workplace safety and productivity.

Trustworthiness in the field of dust collector air filter cartridges is best demonstrated through real-world applications and user testimonials. Businesses across sectors, from woodworking to pharmaceuticals, have seen marked improvements in air quality and equipment performance after upgrading to high-efficiency cartridges. For instance, a renowned furniture manufacturer reported a 30% increase in air quality after replacing their outdated filtration system with modern cartridges, which in turn reduced employee sick days and boosted productivity. Maintenance of dust collector air filter cartridges is paramount to ensure their effectiveness and longevity. Regular inspections for physical wear and tear, coupled with a periodic cleaning schedule, can greatly extend the filter's life. Implementing a pulse-jet cleaning system can automate this process, using compressed air to blow the accumulated dust off the filter surface, thus maintaining airflow and minimizing downtime. For those investing in dust collector air filter cartridges, consideration should be given to the total cost of ownership. While high-efficiency cartridges may have a higher upfront cost, their extended lifespan and reduced energy consumption often result in lower long-term expenses. Additionally, specialized filters designed for specific contaminants can prevent secondary issues, such as machine corrosion or product contamination, thereby safeguarding expensive machinery and enhancing production quality. In conclusion, a strategic approach to selecting and maintaining dust collector air filter cartridges not only improves air quality and compliance with health standards but also optimizes operational efficiency and cost management. By harnessing the latest filtration technologies and adhering to authoritative standards, industries can transform this fundamental component into a pivotal asset for workplace safety and productivity.

Latest news

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: