ONLY Technology (hebei Province) Co., Ltd.

Tel:

+8615930870079

Tel:

+8615930870079

ม.ค. . 15, 2025 04:36 Back to list

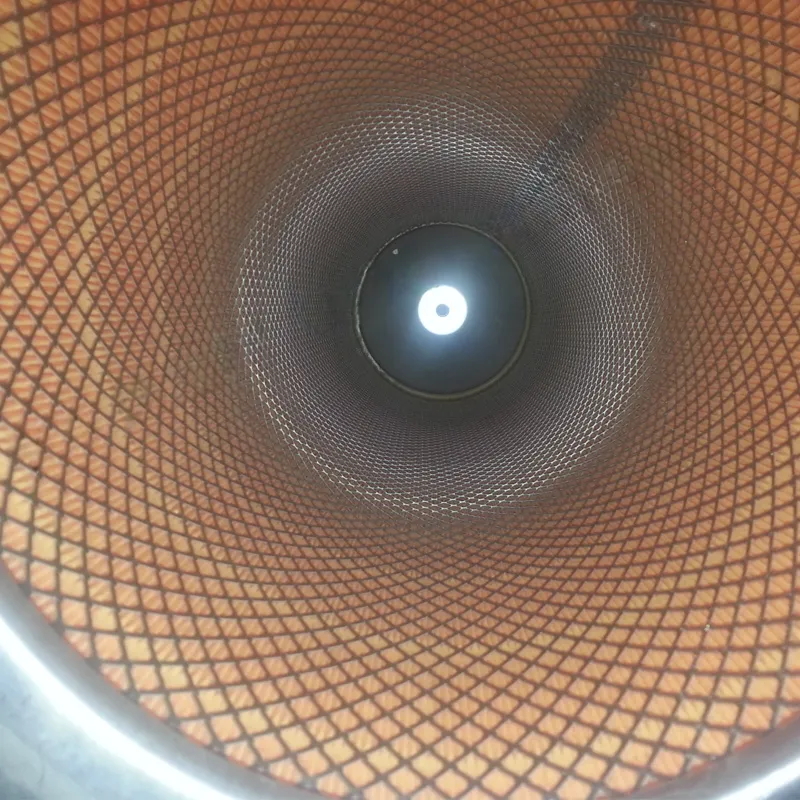

Custom-Made High Grade fine cartridge filter for dust extractor

Dust collector air filter cartridges are pivotal components in industrial environments, where air quality is of utmost importance. As a seasoned expert in air filtration systems, let me walk you through the intricacies of selecting the right cartridge, maintaining it, and ensuring optimal performance.

Authoritative figures in industrial air quality stress the importance of regular monitoring of differential pressure across the filter. This monitoring acts as an early warning system, indicating when a filter may be nearing the end of its service life or when operational adjustments are needed. Systems equipped with digital readouts and alerts take this a step further, ensuring real-time data availability for informed decision-making. Furthermore, leveraging data from these monitoring systems plays a critical role in predictive maintenance strategies. By analyzing trends and patterns in pressure differentials, experts can forecast maintenance needs, thereby avoiding unexpected failures and optimizing filter usage. This proactive approach underscores a commitment to maintaining air quality and operational efficiency. In conclusion, the significance of dust collector air filter cartridges extends beyond mere filtration. It embodies an intersection of material science, design expertise, and maintenance strategy, supported by authoritative endorsements from industry leaders. By understanding these elements and implementing advanced monitoring systems, businesses can ensure they maintain clean air standards, enhance equipment longevity, and ultimately, safeguard the health of their workforce. Trust in quality products and expert guidance remains an investment in your operational future.

Authoritative figures in industrial air quality stress the importance of regular monitoring of differential pressure across the filter. This monitoring acts as an early warning system, indicating when a filter may be nearing the end of its service life or when operational adjustments are needed. Systems equipped with digital readouts and alerts take this a step further, ensuring real-time data availability for informed decision-making. Furthermore, leveraging data from these monitoring systems plays a critical role in predictive maintenance strategies. By analyzing trends and patterns in pressure differentials, experts can forecast maintenance needs, thereby avoiding unexpected failures and optimizing filter usage. This proactive approach underscores a commitment to maintaining air quality and operational efficiency. In conclusion, the significance of dust collector air filter cartridges extends beyond mere filtration. It embodies an intersection of material science, design expertise, and maintenance strategy, supported by authoritative endorsements from industry leaders. By understanding these elements and implementing advanced monitoring systems, businesses can ensure they maintain clean air standards, enhance equipment longevity, and ultimately, safeguard the health of their workforce. Trust in quality products and expert guidance remains an investment in your operational future.

Latest news

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Related PRODUCTS

Copyright © 2025 ONLY Technology (hebei Province) Co., Ltd. All Rights Reserved. Sitemap | Privacy Policy

Email:

Email: