Tel:

+8615930870079

Tel:

+8615930870079

พ.ย. . 25, 2024 05:18 Back to list

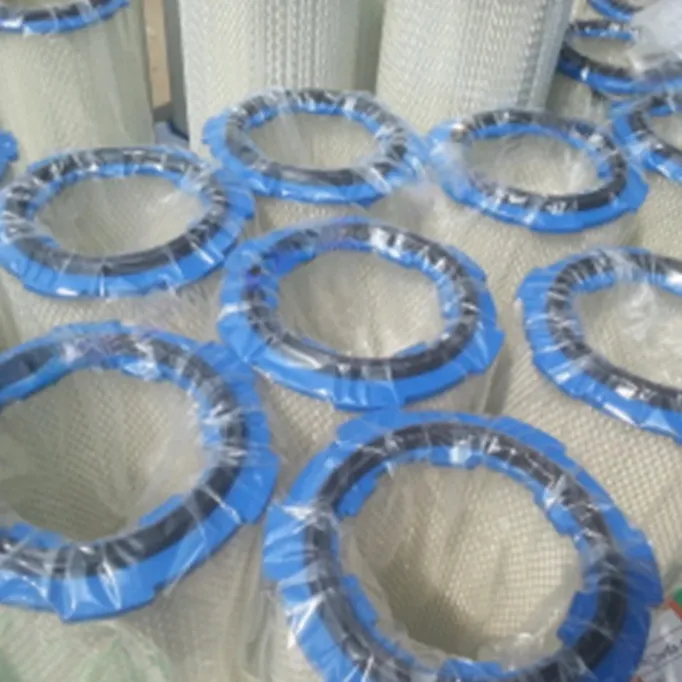

dust cartridges

Understanding Dust Cartridges Importance, Functionality, and Maintenance

In various industrial settings, controlling dust and particulate matter is crucial for the safety and health of workers. One of the most effective solutions to manage air quality is the use of dust cartridges. These components play a pivotal role in filtration systems, ensuring that clean air is circulated within environments that may otherwise be compromised by airborne particles.

What Are Dust Cartridges?

Dust cartridges are specialized filters designed to capture and collect fine dust particles from the air. They can be found in various dust collection systems, including those used in woodworking, metalworking, and food processing industries. Made from a variety of materials, such as polyester, PTFE, or cellulose, these cartridges are engineered to provide high-efficiency filtration, allowing for the effective removal of dust and other contaminants.

Functionality of Dust Cartridges

Dust cartridges work by employing a combination of mechanical and electrostatic filtration mechanisms. When air laden with dust enters the filter, larger particles are captured by the filter media, while smaller particles may adhere to the surface due to electrostatic forces. This dual-action ensures that even the smallest of particles are successfully trapped, preventing them from re-entering the workplace environment.

The design of dust cartridges is crucial for their efficiency. They are typically cylindrical and may feature pleated media to increase their surface area, which enhances dust holding capacity and minimizes resistance to airflow. This is particularly important because maintaining adequate airflow is essential for operational efficiency and equipment longevity.

Applications of Dust Cartridges

dust cartridges

Dust cartridges are used in a variety of applications across many industries. In manufacturing environments where cutting, grinding, or sanding is commonplace, dust cartridges serve to keep the air clean, thereby safeguarding the health of workers and reducing the risk of respiratory issues. In the food processing industry, maintaining a dust-free environment is not only a matter of health but also critical for ensuring product quality and compliance with safety regulations.

Moreover, dust cartridges are integral to the operation of vacuum systems and industrial cyclone collectors. By capturing dust before it reaches the exhaust, these cartridges help maintain cleaner air and protect sensitive machinery from abrasion and damage caused by particulate matter.

Maintenance and Replacement

To ensure the longevity and effectiveness of dust cartridges, regular maintenance is essential. Dust cartridges should be inspected frequently for signs of wear and tear. Over time, filters can become clogged with dust, which not only reduces their effectiveness but can also lead to increased operational costs due to decreased airflow and energy efficiency.

When replacing dust cartridges, it is imperative to choose the right type and size to match the specific requirements of the filtration system. This ensures optimal performance and compliance with industry standards. In some cases, pre-filters or secondary filters may be used in conjunction with dust cartridges to enhance filtration efficiency and extend the lifespan of the primary filters.

Conclusion

In conclusion, dust cartridges are a vital component in maintaining clean air within various industrial environments. Their effective filtration capabilities not only enhance worker safety but also contribute to the overall efficiency of industrial processes. Proper selection, maintenance, and timely replacement of dust cartridges are essential practices that industries must adopt to reduce health risks and ensure compliance with safety regulations. As industries continue to prioritize worker health and environmental sustainability, dust cartridges will remain an indispensable part of air quality management.

-

Nano Fiber Technology: Revolutionizing Cartridge Dust Collector FiltersNewsAug.06,2025

-

How Activated Carbon Air Cartridges Eliminate OdorsNewsAug.06,2025

-

Dust Filter Cartridge Handling Fine Particulate MatterNewsAug.06,2025

-

Cartridge Dust Collector Filter for Welding Fume ExtractionNewsAug.06,2025

-

Activated Carbon Filter Cartridge Effectiveness Against VOCsNewsAug.06,2025

-

Activated Carbon Air Filter Cartridge Benefits ExplainedNewsAug.06,2025

Email:

Email: