Tel:

+8615930870079

Tel:

+8615930870079

ส.ค. . 20, 2024 17:21 Back to list

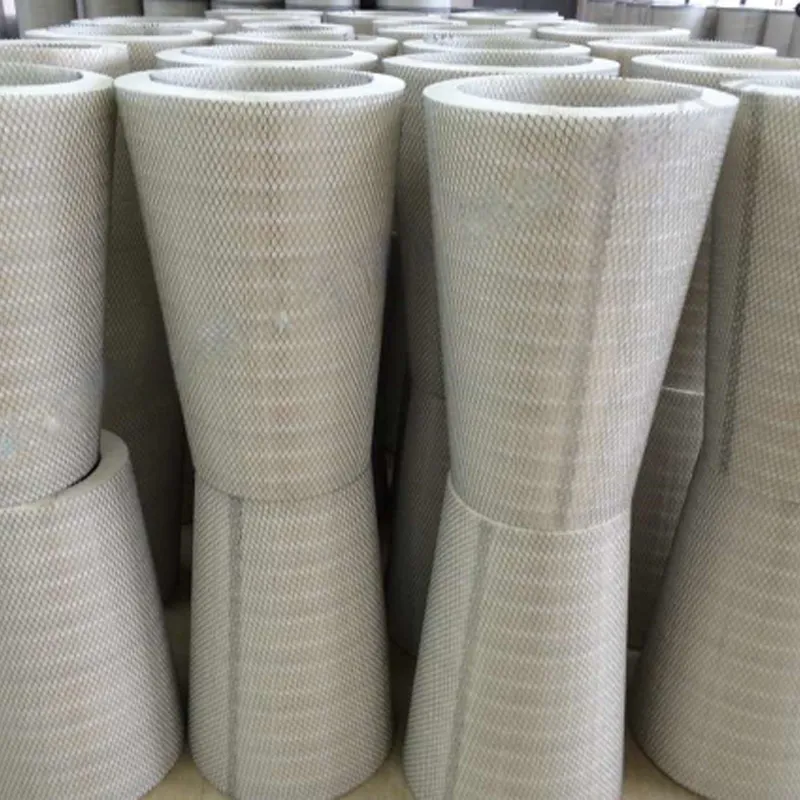

Durable Stainless Steel Filter Elements for Industrial and Commercial Applications

The Importance of Stainless Steel Filter Elements in Modern Filtration Systems

In today's industrial and commercial environments, the need for efficient and reliable filtration systems has become paramount. Among the various options available in the market, stainless steel filter elements stand out due to their durability, versatility, and effectiveness. These filter elements play a pivotal role in ensuring the purity and quality of fluids used across various applications, from water treatment to food processing and chemical manufacturing.

What are Stainless Steel Filter Elements?

Stainless steel filter elements are components used in filtration systems designed to separate solid particles from liquids or gases. Made from high-quality stainless steel, these filters are engineered to withstand harsh environments, high temperatures, and corrosive substances. Their construction allows for a higher degree of mechanical integrity compared to filters made of other materials, making them an ideal choice for demanding applications.

Advantages of Stainless Steel Filter Elements

1. Durability and Longevity

One of the most significant advantages of stainless steel filter elements is their durability. Unlike traditional filters made from paper or synthetic materials, stainless steel filters have a longer lifespan. They are not prone to tearing or breaking, which minimizes downtime and reduces the need for frequent replacements. This longevity translates into cost savings and improved operational efficiency.

2. Corrosion Resistance

Stainless steel is inherently resistant to corrosion, which is crucial for applications involving chemicals, oils, and various fluids. This resistance ensures that the filter maintains its integrity and performance over time, even when exposed to aggressive substances. By using stainless steel filter elements, industries can avoid contamination risks and ensure that their processes remain safe.

stainless steel filter element

Stainless steel filter elements are available in various pore sizes, making them suitable for filtering out different sizes of particles. They provide enhanced filtration efficiency, which is vital for applications that require high purity levels. This capability ensures that downstream processes and final products meet strict quality standards, particularly in sectors such as pharmaceuticals, food and beverage, and electronics.

4. Ease of Cleaning and Reusability

Another notable benefit is that stainless steel filter elements can often be cleaned and reused multiple times. Unlike disposable filters, which contribute to waste and increase costs, reusable stainless steel filters can be easily backwashed or chemical-cleaned to restore their filtering capability. This feature not only supports environmental sustainability but also provides a practical solution for reducing operational costs.

5. Customizability

Stainless steel filter elements can be customized to meet specific filtration requirements. Manufacturers can produce elements in various shapes, sizes, and configurations tailored to particular systems. This versatility allows industries to incorporate filters that perfectly fit their operational needs, ensuring optimal performance.

Applications of Stainless Steel Filter Elements

Stainless steel filter elements find applications in diverse industries, including

- Automotive Used in fuel and lubrication systems to ensure clean fuel flow and protect sensitive engine components. - Pharmaceutical Essential for maintaining high standards of cleanliness and purity in drug manufacturing processes. - Food and Beverage Critical in processes such as brewing and dairy production, where contamination could alter product integrity. - Chemical Processing Employed in filtration systems handling corrosive chemicals to prevent system failure and extend equipment life.

Conclusion

In conclusion, stainless steel filter elements are an indispensable component of modern filtration systems. Their remarkable properties—durability, corrosion resistance, high filtration efficiency, ease of cleaning, and customizability—make them a preferred choice across various industries. As the demand for efficient filtration solutions continues to grow, investing in stainless steel filter elements is a strategic decision that can lead to improved performance, cost savings, and enhanced product quality. Whether for industrial applications or commercial use, the benefits of these filter elements cannot be overstated, ensuring cleaner and safer processes for a sustainable future.

-

Types and Applications of Air Filtration CartridgesNewsJul.28,2025

-

The Role of Gas Turbine FiltersNewsJul.28,2025

-

Mastering Air Filter Cartridge UseNewsJul.28,2025

-

Advanced Turbine Filters for Modern Gas TurbinesNewsJul.28,2025

-

Cellulose Air Filter Cartridge Advantages in Dust FiltrationNewsJul.28,2025

-

Cellulose Filters for Air Particle ReductionNewsJul.28,2025

Email:

Email: